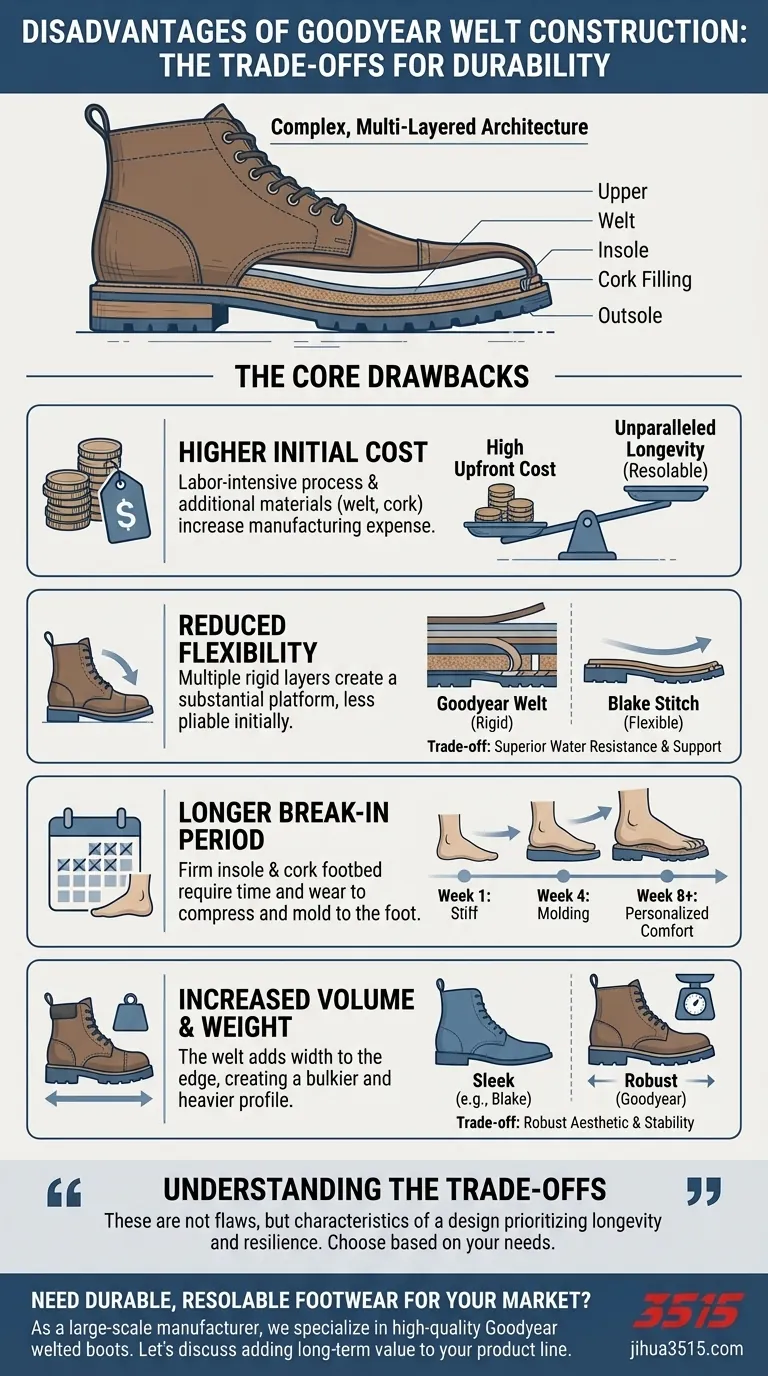

To be direct, the primary disadvantages of Goodyear welt construction are its higher cost, reduced flexibility, and a longer break-in period. These drawbacks are a direct result of the complex, multi-layered construction that also gives this method its renowned durability and water resistance.

While celebrated for longevity, Goodyear welt construction achieves its resilience through trade-offs. Understanding that its disadvantages—cost, stiffness, and bulk—are inseparable from its strengths is the key to making an informed decision.

The Source of the Trade-offs: A Look at the Construction

To understand the disadvantages, you must first appreciate the architecture. The Goodyear welt method is defined by its complexity and use of additional materials.

The Key Components

A strip of leather, rubber, or plastic—the welt—is stitched to the upper and the insole. A layer of cork filling is added to the cavity created by this process. Finally, the outsole is stitched directly to the welt, not the upper.

An Intensive Process

This multi-step process requires more time, more material, and a higher degree of artisan skill compared to simpler methods like cemented or Blake-stitched footwear. This inherent complexity is the root of its primary drawbacks.

The Core Disadvantages Explained

Each benefit of a Goodyear welt comes with an associated cost. These are not necessarily flaws, but rather characteristics of the design that may not suit every user or purpose.

Higher Initial Cost

The labor-intensive nature and the additional materials—the welt and cork filling—directly increase the manufacturing cost. This expense is passed on to the consumer, making Goodyear welted footwear a significant initial investment.

Reduced Flexibility

The multiple layers (insole, upper, welt, cork, outsole) create a rigid and substantial platform. This structure is less flexible out of the box compared to a Blake stitch, where the outsole is stitched directly to the insole, resulting in a more pliable shoe.

A Longer Break-in Period

The same stiffness that reduces initial flexibility also contributes to a more demanding break-in period. The firm insole and cork footbed require time and wear to compress and mold to the unique shape of your foot.

Increased Volume and Weight

The welt adds width to the edge of the sole, creating a bulkier and heavier profile than more streamlined construction methods. While many appreciate this robust aesthetic, it can feel less sleek or formal.

Understanding the Trade-offs: Why These Flaws Exist

The disadvantages of a Goodyear welt are not accidental; they are the price of its celebrated advantages. Viewing them as two sides of the same coin provides a clearer picture.

Cost vs. Longevity

The high upfront cost is a direct trade-off for unparalleled longevity. Because the outsole is stitched to the welt instead of the upper, a cobbler can easily remove and replace the sole multiple times without compromising the shoe's structure.

Stiffness vs. Water Resistance and Support

The rigid, multi-layered construction that causes initial stiffness is also what provides superior water resistance and stability. The welt creates a stronger barrier against moisture seeping in from the ground, and the robust platform offers excellent foot support.

Break-in vs. Personalized Comfort

The challenging break-in period is the precursor to exceptional, long-term comfort. As the cork footbed compresses and the leather molds, the shoe creates a personalized fit that is uniquely supportive to your foot's shape and gait.

Is Goodyear Welt Right for You?

Choosing a construction method means choosing a set of priorities. By aligning the characteristics of a Goodyear welt with your specific needs, you can determine if it's the correct choice.

- If your primary focus is maximum durability and long-term value: The ability to resole the footwear makes Goodyear welt the superior choice, justifying the initial cost and break-in period.

- If your primary focus is a sleek profile and immediate flexibility: A construction method like the Blake stitch will better serve your needs, though you will sacrifice some water resistance and durability.

- If your primary focus is out-of-the-box comfort with no break-in: You may prefer a cemented construction, understanding that it cannot be resoled and will have a significantly shorter lifespan.

Ultimately, choosing Goodyear welted footwear is an investment in a product designed to last, adapt, and be renewed over many years of service.

Summary Table:

| Disadvantage | Core Reason |

|---|---|

| Higher Initial Cost | Labor-intensive process and use of additional materials (welt, cork). |

| Reduced Flexibility | Multiple layers (insole, upper, welt, cork, outsole) create a rigid structure. |

| Longer Break-in Period | Firm insole and cork footbed require time to mold to the foot's shape. |

| Increased Bulk & Weight | The welt adds width, resulting in a heavier, less sleek profile. |

Need Durable, Resolable Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We specialize in crafting high-quality Goodyear welted boots and shoes that balance durability with comfort. Our production capabilities encompass all types of shoes and boots, ensuring you get the right product for your customers' needs.

Let's discuss how our manufacturing expertise can add long-term value to your product line.

Contact our team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene