At first glance, all firefighter boots look tough, but their designs are engineered for fundamentally different battlefields. A structural firefighting boot is a piece of heavy armor, built with safety toes, puncture-proof soles, and extreme heat resistance for urban environments. In contrast, a wildland firefighting boot is a specialized endurance tool, made of durable leather with aggressive traction and breathability for hiking miles over rugged, unpredictable terrain.

The core difference isn't just the material, but the mission. Structural boots are built for short, intense battles against extreme hazards within a structure, while wildland boots are designed for long-duration campaigns across challenging natural landscapes.

The Mission Dictates the Design

The most significant factor driving the differences between these boots is the environment where they will be used. Each hazard profile demands a unique set of protective features.

Structural Boots: The Urban Fortress

Structural boots are designed for fires inside buildings. Firefighters face threats from falling debris, sharp objects like nails and glass on the ground, extreme conductive heat, and the need to climb ladders.

The boot acts as a shield. Its primary purpose is to provide maximum protection against a wide array of immediate, high-intensity threats in a relatively confined space.

Wildland Boots: The All-Terrain Hiker

Wildland boots are built for the outdoors. Firefighters may spend 12 hours or more on their feet, hiking up steep mountainsides, navigating loose rock, and crossing uneven ground, all while carrying heavy gear.

The boot is a tool for mobility and endurance. It must provide stability and protection from ambient heat while remaining comfortable enough for what is essentially extreme, long-distance hiking.

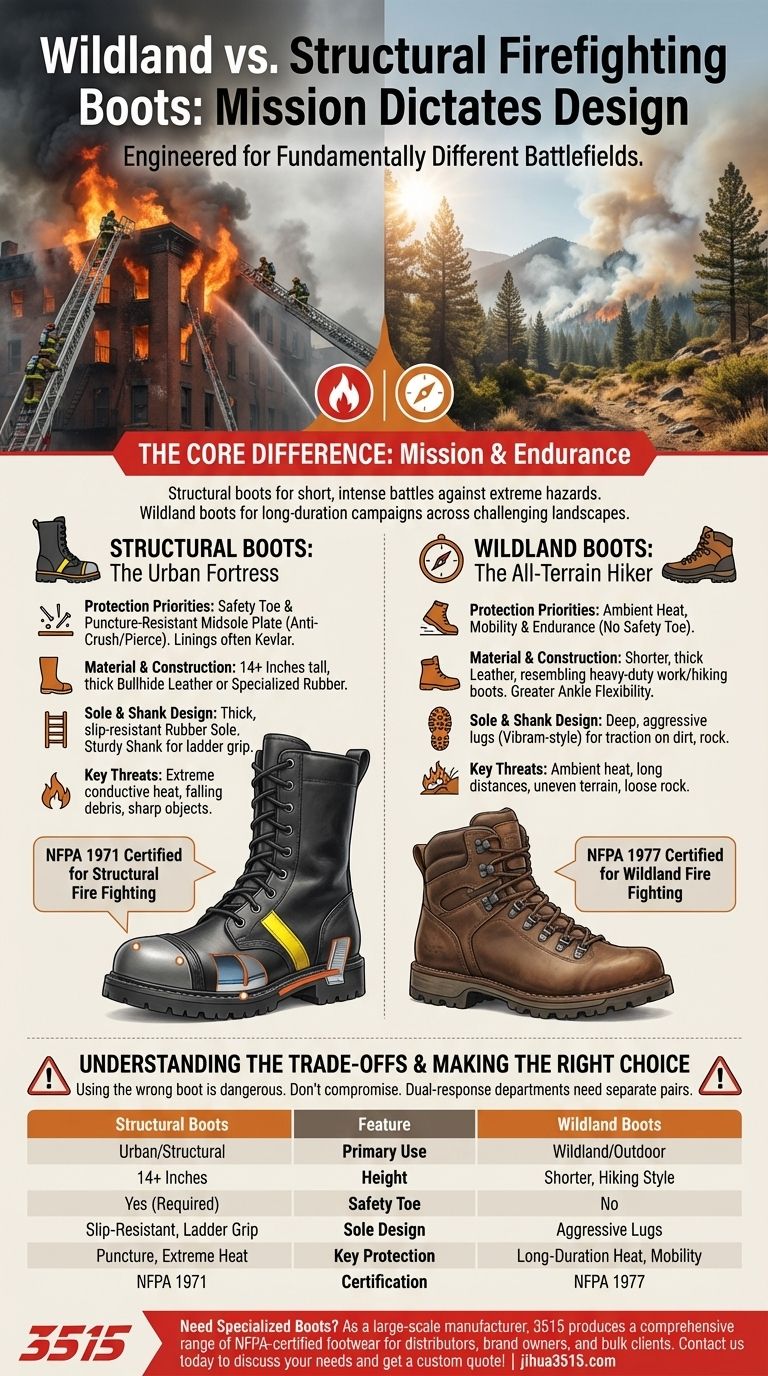

A Head-to-Head Feature Comparison

Understanding the specific design choices reveals why each boot is perfectly suited for its task.

Protection Priorities

A structural boot must have a safety toe and a puncture-resistant midsole plate to protect against crushing and piercing injuries from building collapse and debris. Linings are often made of materials like Kevlar for thermal and cut protection.

A wildland boot, however, prioritizes protection from ambient heat over long periods. It lacks a safety toe, as the risk comes from fire and terrain, not falling beams.

Material and Construction

Structural boots are typically much taller, often 14 inches or more, to protect the shin. They can be made of thick, treated bullhide leather or specialized rubber compounds.

Wildland boots are almost always made of thick leather and resemble heavy-duty work or hiking boots. Their shorter height allows for greater ankle flexibility, which is critical for navigating uneven ground.

Sole and Shank Design

The sole of a structural boot is thick, often rubber, and designed for heat and slip resistance on wet floors. It includes a sturdy shank specifically to provide support and grip on ladder rungs.

Wildland boots feature deep, aggressive lugs on their Vibram or similar-style soles. This design is purely for traction on dirt, rock, and loose soil.

Understanding the Trade-offs

Choosing the wrong boot for the job is not just inefficient—it's dangerous.

Why You Can't Use One for the Other

Using a heavy, rigid structural boot on a wildland fire would lead to rapid exhaustion and an increased risk of slips and falls due to its poor traction on natural terrain.

Conversely, wearing a flexible wildland boot to a structure fire would be catastrophic. It offers no protection from punctures by nails, no safety toe for impacts, and insufficient protection from the intense, conductive heat found inside a burning building.

The Leather vs. Rubber Debate

For structural boots, departments often choose between leather and rubber. Rubber boots offer superior waterproofing and are often easier to decontaminate.

Leather boots typically provide better ankle support, are lighter (reducing fatigue), and offer better breathability, but they come at a higher cost. Both materials can meet the necessary NFPA 1971 safety standards.

The Critical Role of Certification

Each boot type is governed by its own safety standard set by the National Fire Protection Association (NFPA). Compliance is non-negotiable and ensures the boot has been rigorously tested for the specific hazards it was designed to face.

Making the Right Choice for Your Role

Selecting the correct footwear is a foundational element of firefighter safety and operational effectiveness.

- If your primary focus is urban and suburban structure fires: You need a certified structural boot with a safety toe, puncture-resistant sole, and tall shaft for maximum protection.

- If your primary focus is wildland or the wildland-urban interface (WUI): You need a durable leather wildland boot designed for hiking, with excellent traction and all-day comfort.

- If you work in a dual-response department: Never compromise. The only safe and effective solution is to have two separate, specialized pairs of boots and use the correct one for every call.

Choosing the right boot is a critical decision that directly impacts your safety, endurance, and effectiveness on the ground.

Summary Table:

| Feature | Structural Boots | Wildland Boots |

|---|---|---|

| Primary Use | Urban/structural fires | Wildland/outdoor terrain |

| Height | 14+ inches | Shorter, hiking boot height |

| Safety Toe | Yes (required) | No |

| Sole Design | Slip-resistant for wet surfaces | Aggressive lugs for natural terrain |

| Key Protection | Puncture resistance, extreme heat | Long-duration heat, mobility |

| Certification | NFPA 1971 | NFPA 1977 |

Need specialized firefighting boots tailored to your mission? As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Whether you require the heavy-duty protection of structural boots or the rugged endurance of wildland boots, our production capabilities ensure top-quality gear for every firefighting scenario. Contact us today to discuss your specific needs and get a custom quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the key features of police tactical boots? Essential Gear for Law Enforcement Performance

- What are the advantages of side-zip boots? Unmatched Speed and Daily Convenience

- Why is choosing the right footwear important for wildland firefighting? Ensure Safety & Endurance on the Fireline

- What are the key considerations when choosing police footwear? Select the Right Boots for Safety & Performance

- Why is the weight of police boots an important consideration? Balance Fatigue & Protection for Peak Performance

- What are the three main components of police footwear? The Anatomy of a High-Performance Duty Boot

- Why is support important in police boots? Prevent Injury & Boost Performance

- Why is footwear important for law enforcement officers? Boost Endurance, Safety & Performance