At a fundamental level, the primary difference between standard synthetic and TPU horse boot materials comes down to performance and fit. Thermoplastic Polyurethane (TPU) is a high-quality, flexible material that molds to the horse's leg for superior protection and comfort. In contrast, "synthetic" typically refers to less expensive, more rigid plastics that are heavier and lack the ability to provide a custom-like fit.

The choice between boot materials is not merely about price; it's a critical decision that balances upfront cost against the long-term durability, protective capability, and comfort your horse receives.

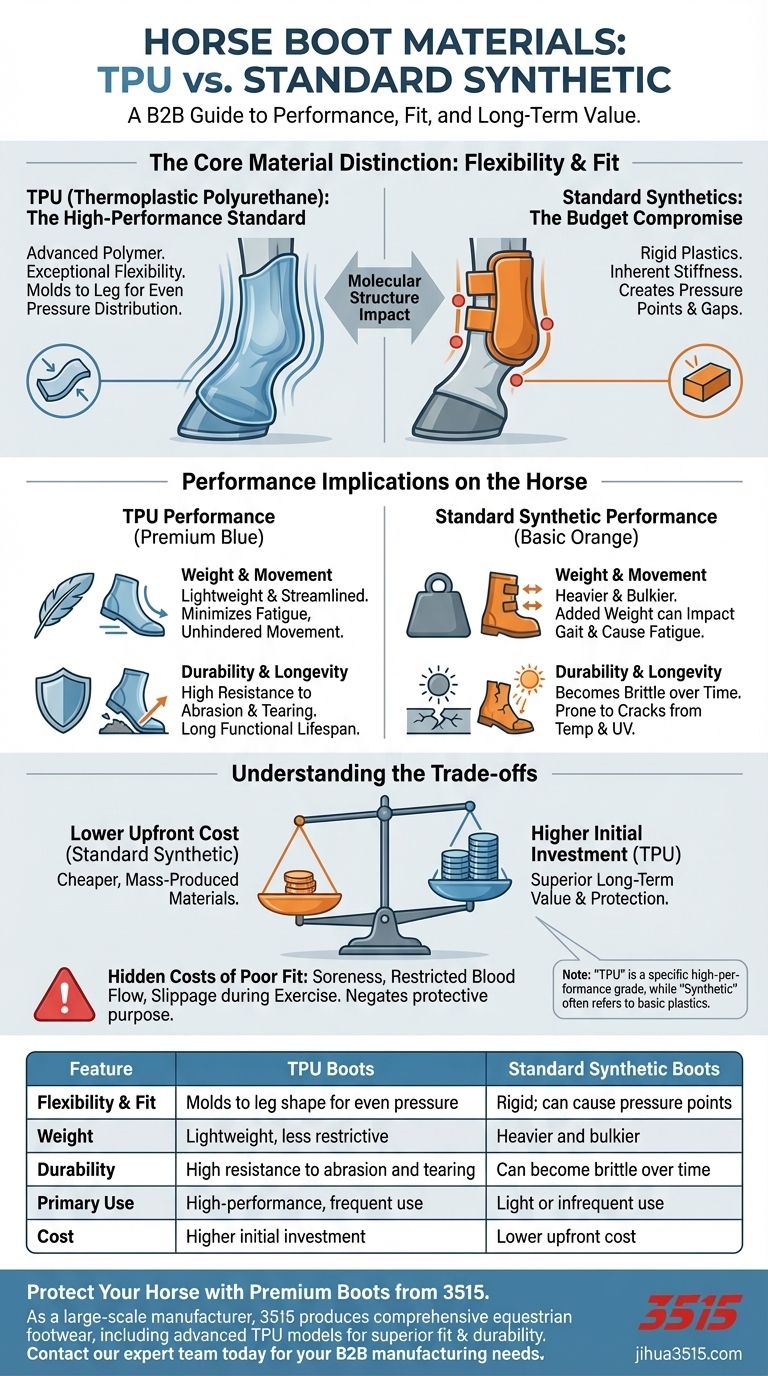

The Core Material Distinction: Flexibility and Fit

The most significant differentiator between these materials is their molecular structure, which directly impacts how the boot interacts with the horse's leg.

TPU: The High-Performance Standard

Thermoplastic Polyurethane (TPU) is an advanced polymer known for its exceptional flexibility and resilience. This allows a boot to conform closely to the unique contours of a horse's leg.

This "molding" capability is crucial because it distributes pressure evenly, minimizing the risk of rubbing or uncomfortable friction during intense work.

Standard Synthetics: The Budget Compromise

Most less expensive synthetic boots are molded from common, rigid plastics. These materials prioritize low production costs over functional performance.

Their inherent stiffness prevents them from adapting to the leg's shape. This can create pressure points and gaps, potentially compromising both comfort and protection.

Performance Implications on the Horse

The material's properties directly translate into how the boot performs under stress and affects the horse's movement.

Weight and Freedom of Movement

Cheaper synthetic boots tend to be heavier and bulkier. While seemingly minor, this added weight can impact a horse's natural gait and lead to faster fatigue.

TPU, by contrast, offers a superior strength-to-weight ratio. This allows for the design of lightweight, streamlined boots that protect without hindering movement.

Durability and Longevity

Durability is where the initial investment in a higher-quality material pays off. TPU is highly resistant to abrasion, tearing, and environmental factors.

Less expensive plastics can become brittle over time, especially with exposure to temperature changes and UV light, leading to cracks and a shorter functional lifespan.

Understanding the Trade-offs

Choosing the right material requires an objective look at both the initial investment and the potential hidden costs.

The Clear Cost Factor

Standard synthetic boots are undeniably less expensive upfront. Their lower price point is a direct result of using cheaper, mass-produced plastic materials.

The Hidden Costs of a Poor Fit

A boot that doesn't fit well is a liability. The rigidity of cheaper synthetics can lead to sores, restricted blood flow, or slippage during exercise, which negates the boot's protective purpose.

Not All "Synthetics" Are Equal

It's important to understand that TPU is technically a type of synthetic material. The key is the grade of the material. When evaluating boots, "synthetic" often serves as a catch-all for basic plastics, while "TPU" signifies a specific, high-performance polymer engineered for demanding applications.

Making the Right Choice for Your Horse

Your decision should be guided by your specific goals for performance, protection, and long-term value.

- If your primary focus is initial affordability for light or infrequent use: A standard synthetic boot may be adequate, but you must be vigilant about checking for proper fit and signs of rubbing.

- If your primary focus is high-performance, optimal comfort, and long-term durability: A TPU boot is the definitive choice, providing a superior investment in your horse's protection and well-being.

Ultimately, selecting the right material is a direct investment in your horse's comfort and safety.

Summary Table:

| Feature | TPU Boots | Standard Synthetic Boots |

|---|---|---|

| Flexibility & Fit | Molds to leg shape for even pressure | Rigid; can cause pressure points |

| Weight | Lightweight, less restrictive | Heavier and bulkier |

| Durability | High resistance to abrasion and tearing | Can become brittle over time |

| Primary Use | High-performance, frequent use | Light or infrequent use |

| Cost | Higher initial investment | Lower upfront cost |

Protect Your Horse with Premium Boots from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of performance boots, including advanced TPU models designed for superior fit and durability.

We can help you provide the best protection for your customers' horses. Contact our expert team today to discuss your boot manufacturing needs.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do you estimate the correct boot size for a horse? A Guide to Accurate Measurement and Fit

- Why is it necessary to define a digital skill matrix in footwear labor management? Achieve Precision and Consistency

- Why is the use of high-performance footwear necessary during the biomechanical adjustment and dynamic capture process?

- How do weather conditions affect motorcycle boot selection? Choose the Right Gear for Safety and Comfort

- How do integrated vibratory motors in smart insoles optimize dynamic balance control? Mastering Stochastic Resonance

- What is the purpose of integrating thin-film pressure sensors into an industrial exoskeleton? Enhance Foot Stability

- How does high-quality PPE influence safety culture in the ABC model? Boost Compliance with Premium Gear

- What are the main applications of PVC in manufacturing? From Pipes to Medical Tubing