The fundamental difference between steel toe and composite toe boots lies in the material used for the protective toe cap. Steel toe boots use a heavy-duty steel cap for maximum resistance against crushing and impact. Composite toe boots use non-metallic materials like carbon fiber, Kevlar, or advanced plastics to provide a lighter-weight, non-conductive alternative that still meets mandated safety standards.

Your choice is not about which boot is universally "better," but which is strategically suited to your specific workplace hazards. Steel offers the pinnacle of strength for heavy industry, while composite provides versatile protection against a wider range of environmental risks like electricity, extreme temperatures, and security screenings.

A Head-to-Head Material Comparison

To understand which boot is right for you, we must first examine the core materials that define their function and performance.

The Steel Toe Standard

Steel toe caps are the traditional and most established form of safety footwear protection. They are forged from solid steel.

This construction gives them exceptional strength against both direct impacts from falling objects and steady compression forces, such as from a vehicle rollover.

The Composite Toe Alternative

Composite toe caps are engineered from a blend of non-metallic materials. These can include carbon fiber, plastic, fiberglass, or Kevlar.

The goal of this design is to create a protective cap that is significantly lighter than steel while still meeting the same official safety requirements.

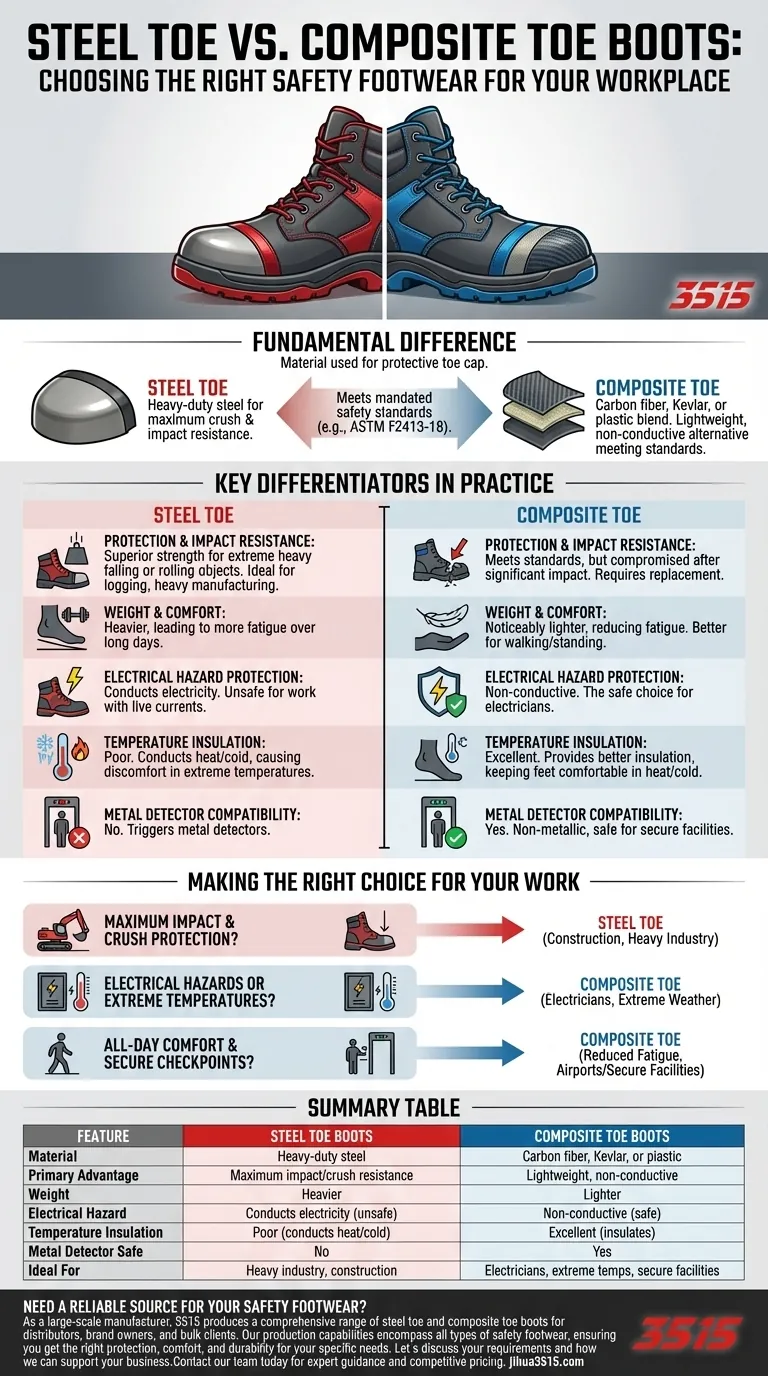

Key Differentiators in Practice

While both boot types must pass the same baseline safety tests, their material differences lead to distinct advantages and disadvantages in the field.

Protection and Impact Resistance

Steel toe caps generally offer superior resistance to extreme impact and compression. For environments with a high risk of heavy falling or rolling objects, such as logging or heavy manufacturing, steel provides the highest level of raw strength.

Composite toes meet the same ASTM F2413-18 safety standards for impact and compression, but they may not withstand repeated impacts as effectively. After one significant impact, a composite toe's structural integrity is compromised and the boot must be replaced.

Weight and All-Day Comfort

This is the most significant advantage of composite materials. Composite toe boots are noticeably lighter than their steel counterparts.

This weight reduction translates directly to less fatigue for the wearer over a long workday, making them a preferred choice for jobs that require constant walking or standing.

Electrical Hazard Protection

Composite materials do not conduct electricity. This makes composite toe boots the only safe choice for electricians or anyone working in environments with a risk of live electrical currents.

Steel is a highly conductive metal, making steel toe boots an unacceptable hazard in these specific situations.

Temperature Insulation

Metal is an excellent conductor of thermal energy. In very cold or hot environments, a steel toe cap will transfer the ambient temperature directly to the foot, causing significant discomfort.

Composite materials are poor thermal conductors, providing far better insulation and keeping the foot more comfortable in extreme weather conditions.

Metal Detector Compatibility

Because they are non-metallic, composite toe boots will not trigger metal detectors. This is a critical feature for workers in airports, nuclear plants, and other secure facilities that require frequent security screenings.

Understanding the Trade-offs

Neither option is perfect for every scenario. Acknowledging their limitations is key to making an informed decision.

The Cost Factor

Advanced materials often come at a higher price. Composite toe boots are typically more expensive than comparable steel toe models due to the higher cost of manufacturing carbon fiber and Kevlar components.

Durability After a Severe Impact

A steel toe cap may bend or dent under a force that exceeds its rating, but it often remains in one piece, potentially offering some residual protection.

A composite toe, upon reaching its failure point, is more likely to crack or shatter. Once this happens, it offers no further protection and presents a different kind of hazard.

The Myth of Being "Less Safe"

It is crucial to understand that any boot labeled with an ASTM safety rating provides proven protection. The choice is not between a "safe" and "unsafe" boot, but between different tools designed for different jobs.

Making the Right Choice for Your Work

To select the right boot, align its primary advantages with the most common and serious hazards you face daily.

- If your primary focus is maximum impact and crush protection: Choose steel toe boots for their unparalleled strength, which is ideal for construction, logging, or heavy industrial settings.

- If your primary focus is working around electrical hazards or in extreme temperatures: Select composite toe boots for their essential non-conductive and insulating properties.

- If your primary focus is all-day comfort and passing through metal detectors: Opt for lightweight composite toe boots to reduce fatigue and move efficiently through secure checkpoints.

Ultimately, understanding the specific demands of your job is the key to choosing footwear that offers not just compliance, but true functional safety.

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Material | Heavy-duty steel | Carbon fiber, Kevlar, or plastic |

| Primary Advantage | Maximum impact/crush resistance | Lightweight, non-conductive |

| Weight | Heavier | Lighter |

| Electrical Hazard | Conducts electricity (unsafe) | Non-conductive (safe) |

| Temperature Insulation | Poor (conducts heat/cold) | Excellent (insulates) |

| Metal Detector Safe | No | Yes |

| Ideal For | Heavy industry, construction | Electricians, extreme temps, secure facilities |

Need a reliable source for your safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get the right protection, comfort, and durability for your specific needs.

Let's discuss your requirements and how we can support your business. Contact our team today for expert guidance and competitive pricing.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene