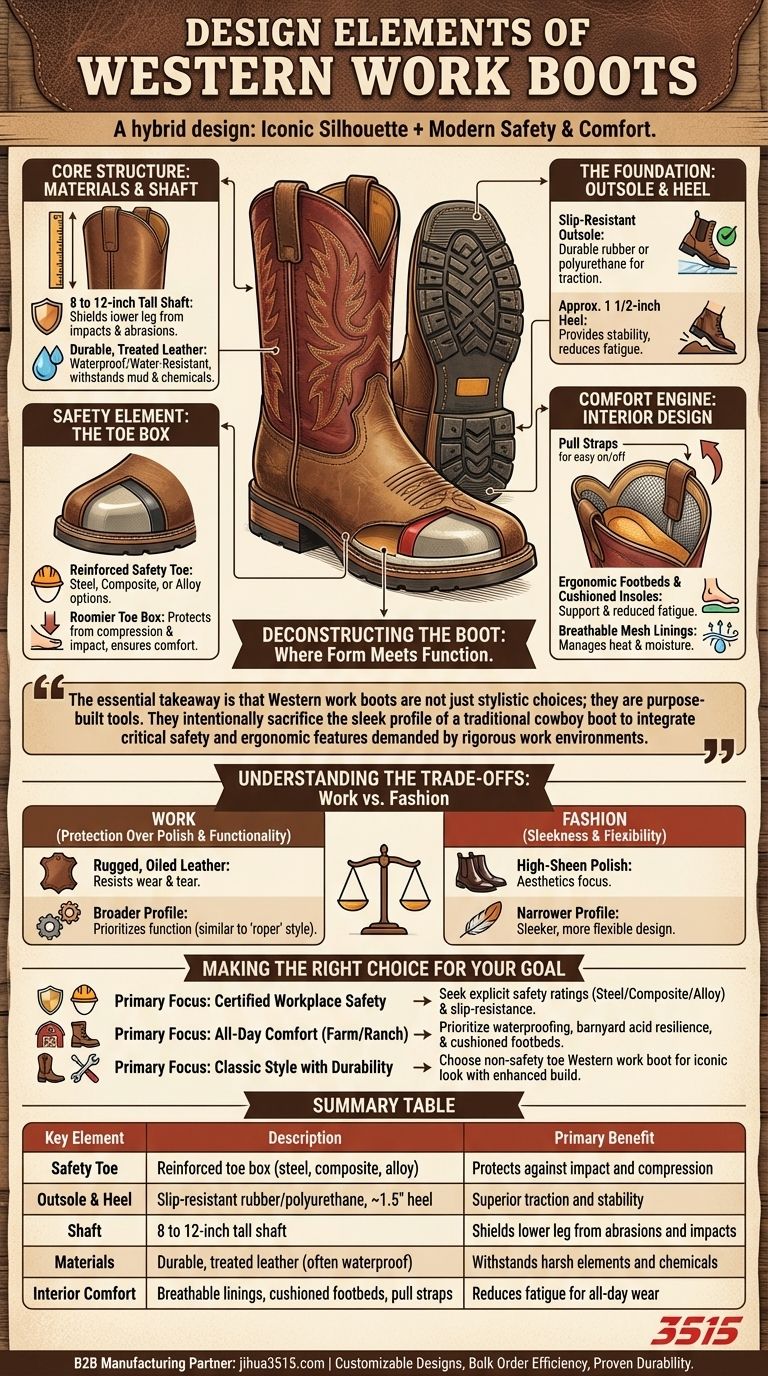

At its core, a Western work boot is a hybrid design that merges the iconic silhouette of a traditional cowboy boot with modern features engineered for safety and comfort. The key design elements include a tall 8 to 12-inch shaft for protection, a dedicated safety toe (steel, composite, or alloy), a slip-resistant rubber or polyurethane outsole, and interior comfort technology like breathable mesh linings and cushioned footbeds.

The essential takeaway is that Western work boots are not just stylistic choices; they are purpose-built tools. They intentionally sacrifice the sleek profile of a traditional cowboy boot to integrate critical safety and ergonomic features demanded by rigorous work environments.

Deconstructing the Boot: Where Form Meets Function

To truly understand the Western work boot, you must analyze how each component serves a specific, practical purpose, blending heritage with modern occupational requirements.

The Foundation: Outsole and Heel

The outsole is the boot's direct interface with the ground, and in a work environment, traction is paramount. Unlike the traditional smooth leather sole, work boots use durable rubber or polyurethane.

These materials are chosen specifically for their slip-resistant properties on various surfaces. The heel, typically around 1 1/2 inches, provides stability and helps distribute weight evenly to reduce fatigue during long hours of standing.

The Core Structure: Materials and Shaft

Western work boots are built for resilience. They are constructed from durable, high-quality leather and are often treated with a waterproof or water-resistant coating.

This construction is designed to withstand harsh elements like mud, water, and even corrosive barnyard acids. The tall 8 to 12-inch shaft is a classic Western feature that serves a critical protective role, shielding the lower leg and ankle from impacts and abrasions.

The Safety Element: The Toe Box

This is a primary differentiator from fashion-oriented Western boots. While traditional boots often feature a narrow or pointed toe, work boots have a roomier toe box for all-day comfort.

Crucially, they incorporate a reinforced safety toe. These can be made of steel, composite, or alloy materials to protect the foot from compression and impact hazards on a job site.

The Comfort Engine: Interior Design

Long workdays require features that minimize foot fatigue. Western work boots integrate ergonomic footbeds and cushioned insoles for support.

To manage heat and moisture, they are often fitted with breathable interior mesh linings, ensuring a more comfortable internal environment. Pull straps remain a key feature, allowing for easy on and off.

Understanding the Trade-offs: Work vs. Fashion

Choosing a Western work boot involves acknowledging a clear set of priorities. It is engineered for performance, which creates distinct differences from a boot designed purely for style.

Protection Over Polish

The materials used for safety and durability often mean the boot is less sleek. The high-sheen polish of a dress boot is replaced by rugged, often oiled leather designed to resist wear and tear.

Weight and Flexibility

The addition of a safety toe and a thick rubber outsole inevitably adds weight and reduces flexibility compared to a traditional leather-soled boot. This is the direct trade-off for superior protection and traction.

A Focus on Functionality

While they retain classic Western-style decorative stitching, the overall design prioritizes function. The profile is often broader and more grounded, reflecting its similarity to the practical "roper" style of boot.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on its intended application. Your primary need should guide your decision.

- If your primary focus is certified workplace safety: Seek out models with explicitly rated steel, composite, or alloy toes and specified slip-resistant outsoles that meet job site requirements.

- If your primary focus is all-day comfort for farm or ranch work: Prioritize boots with waterproofing, resilience to barnyard acids, and cushioned, ergonomic footbeds.

- If your primary focus is blending classic style with enhanced durability: A non-safety toe Western work boot offers the iconic look with a far more resilient and comfortable build than a standard fashion boot.

Ultimately, understanding these design elements empowers you to choose a boot that serves as a reliable tool for your specific needs.

Summary Table:

| Key Element | Description | Primary Benefit |

|---|---|---|

| Safety Toe | Reinforced toe box (steel, composite, alloy) | Protects against impact and compression |

| Outsole & Heel | Slip-resistant rubber/polyurethane, ~1.5" heel | Superior traction and stability |

| Shaft | 8 to 12-inch tall shaft | Shields lower leg from abrasions and impacts |

| Materials | Durable, treated leather (often waterproof) | Withstands harsh elements and chemicals |

| Interior Comfort | Breathable linings, cushioned footbeds, pull straps | Reduces fatigue for all-day wear |

Ready to Equip Your Team with Superior Western Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, including purpose-built Western styles designed for maximum protection and comfort.

We provide:

- Customizable Designs: Tailor boots to meet specific safety standards and brand requirements.

- Bulk Order Efficiency: Streamlined production for large-volume clients.

- Proven Durability: Boots built to withstand the toughest work environments.

Let's discuss your specific needs. Contact our team today for a quote and learn how 3515 can be your trusted manufacturing partner.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What is the necessity of seamless lining in footwear? Enhance Comfort and Clinical Safety in Professional Boots

- What are the key features of Rigmaster boots? Unmatched Safety for Harsh Industrial Work

- How did engineer boots evolve in the 20th century? From Workwear to Counterculture Icon

- What additional comfort features might work boots include? Engineered Systems for All-Day Performance

- How can you achieve a Classic Workwear Vibe with moc toe boots? Build a Rugged, Authentic Style

- What insulation options are available for Wellington work boots? Choose the Right Warmth for Your Job

- How long can heavily worn but well-maintained Goodyear-welted shoes last? 5-10+ Years with Proper Care

- What is the difference between traditional cowboy boots and roper boots? Choose the Right Boot for Your Needs