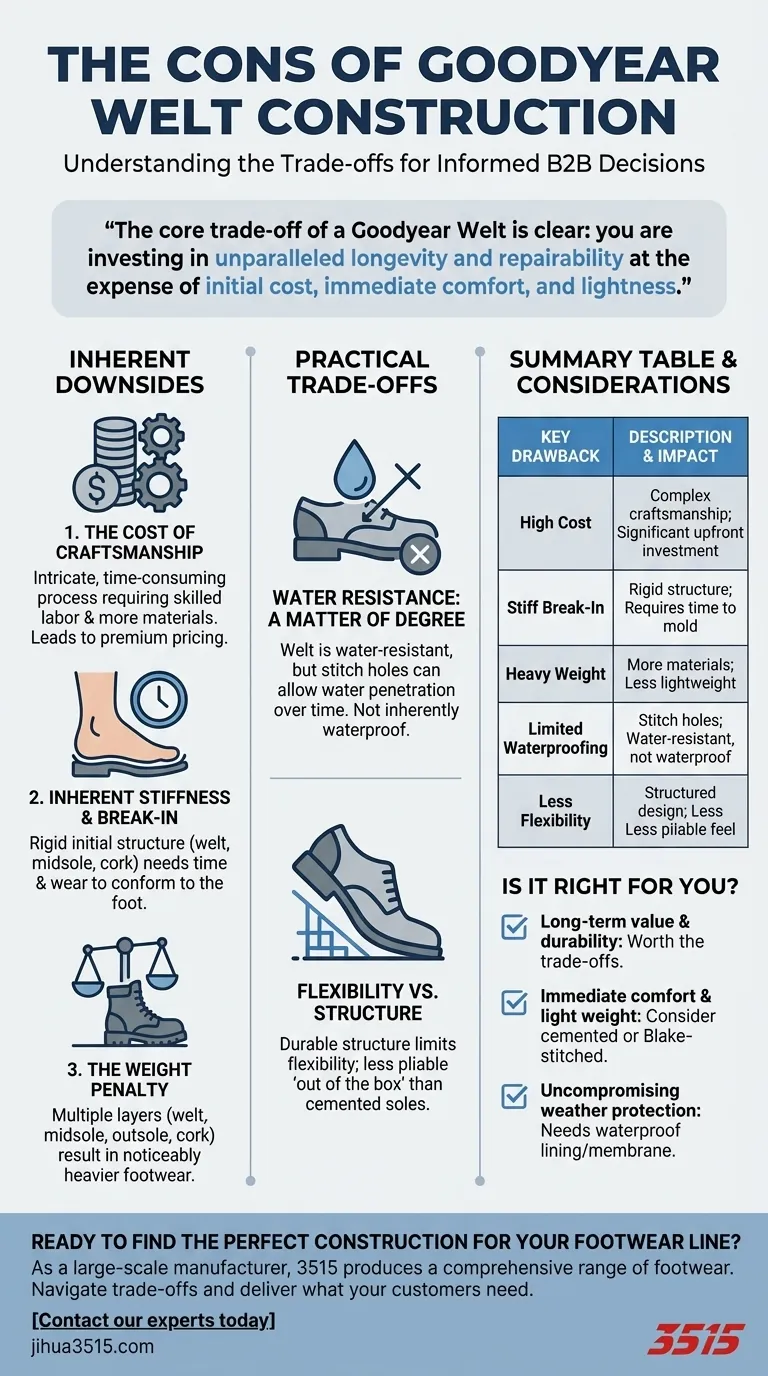

While revered for its durability, Goodyear Welt construction is not without its drawbacks. Its primary cons are a significantly higher cost due to complex craftsmanship, a stiff initial feel requiring a lengthy break-in period, and a heavier weight compared to more modern construction methods.

The core trade-off of a Goodyear Welt is clear: you are investing in unparalleled longevity and repairability at the expense of initial cost, immediate comfort, and lightness. Understanding this balance is key to deciding if it's the right choice for your needs.

Why Goodyear Welt Has Inherent Downsides

To understand the cons, you must first understand the construction. A Goodyear Welt involves stitching a strip of leather (the welt) to both the shoe's upper and insole. The outsole is then stitched directly to this welt, creating a robust and easily replaceable structure.

The Cost of Craftsmanship

The process is intricate and time-consuming, requiring skilled labor and more materials. This multi-step method is a primary driver of the premium price associated with Goodyear Welted footwear.

Inherent Stiffness and Break-In

The combination of the leather welt, an additional midsole, and a cork-filled cavity between the insole and outsole creates a very rigid initial structure. This robust platform needs time and wear to conform to the shape of your foot, resulting in a notable break-in period.

The Weight Penalty

More layers mean more weight. The leather welt, midsole, outsole, and cork filling all contribute to a shoe that is noticeably heavier than one with a simpler, cemented construction.

Understanding the Practical Trade-offs

While often called the "gold standard," the Goodyear Welt method involves specific compromises that are important to recognize, especially concerning environmental factors and comfort.

Water Resistance: A Matter of Degree

The welt creates a strong barrier that effectively keeps water from seeping in from the sides. However, the stitch holes through which the welt is attached can eventually allow water to penetrate, especially with prolonged exposure or submersion.

Therefore, while a Goodyear Welt is highly water-resistant, it is not inherently waterproof without additional features like a waterproof membrane.

Flexibility vs. Structure

The same structure that makes the shoe durable and supportive also makes it less flexible. Footwear with cemented or Blake-stitched soles will almost always feel more pliable and less cumbersome "out of the box."

Price vs. True Longevity

The high initial cost can be a significant barrier. However, the key benefit is resoleability. Because the outsole is stitched to the welt and not the upper, a cobbler can easily replace a worn-out sole multiple times.

This extends the shoe's lifespan for years or even decades, potentially making it a better long-term value than purchasing and replacing several cheaper pairs.

Is Goodyear Welt the Right Choice for You?

Choosing the right shoe construction depends entirely on your priorities. The cons are only cons if they conflict with your primary goal.

- If your primary focus is long-term value and durability: The higher initial cost and break-in period are worthwhile trade-offs for footwear that can last for decades.

- If your primary focus is immediate comfort and light weight: You will likely be better served by a cemented or Blake-stitched shoe that prioritizes flexibility from the first wear.

- If your primary focus is uncompromising weather protection: A Goodyear Welt alone is not enough; seek out footwear that also incorporates a dedicated waterproof lining or membrane.

Ultimately, understanding these compromises allows you to invest in footwear that truly serves your needs.

Summary Table:

| Key Drawback | Description | Impact on Wearer |

|---|---|---|

| High Cost | Complex, labor-intensive craftsmanship | Significant upfront investment |

| Stiff Break-In | Rigid structure from multiple layers | Requires time to mold to the foot |

| Heavy Weight | More materials (welt, midsole, cork) | Less lightweight than other methods |

| Limited Waterproofing | Stitch holes can allow water penetration | Water-resistant, not fully waterproof |

| Less Flexibility | Structured design prioritizes durability | Less pliable 'out-of-the-box' feel |

Ready to Find the Perfect Construction for Your Footwear Line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your priority is the classic durability of a Goodyear Welt or the immediate comfort of modern methods, our production capabilities encompass all types of shoes and boots. We can help you navigate these trade-offs to deliver exactly what your customers need.

Contact our experts today to discuss your manufacturing needs and get a custom quote.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

People Also Ask

- What are the best storage practices for fire boots? Keep Your Gear Ready & Extend Its Lifespan

- What is Injection-Molded Construction in work boots? A Guide to Seamless Durability

- What are the key features for work boots for roofers? Prioritize Grip, Stability, and Safety

- How do you apply boot wax for waterproofing? Achieve a Durable, Moisture-Repellent Seal

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments

- What materials are used in work boots and western boots? Choose the Right Boot for Your Job and Style

- What makes a shoe a work shoe? Discover the Essential Features for Safety & Support

- What conditions are water-resistant boots suitable for? Optimal Comfort for Light Moisture