The primary concern with using leather turnout boots in hazardous materials environments is their inherent difficulty in being decontaminated. Unlike rubber, the porous and natural structure of leather can absorb and retain chemical agents, especially when the boot's surface is scuffed or compromised. This creates a significant risk of secondary exposure long after the initial incident is over.

The choice between leather and rubber boots for hazmat response is fundamentally a choice between material properties. Leather's porous nature makes it a potential liability due to absorption, whereas rubber's non-porous surface provides a more reliable and easily decontaminated barrier against chemical hazards.

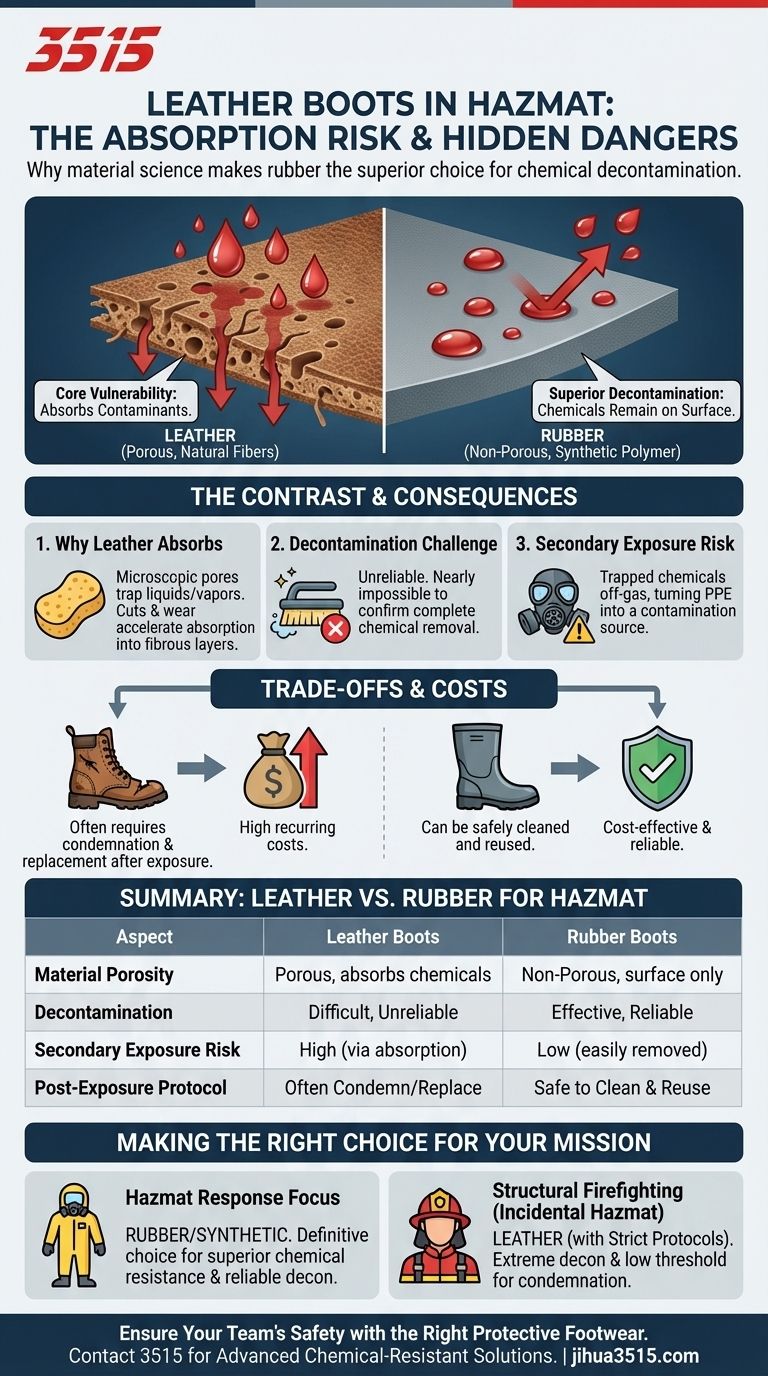

The Core Vulnerability: Material Absorption

In a hazardous materials incident, your equipment's ability to be fully cleaned is as important as its initial ability to protect you. This is where the material science of your boots becomes critical.

Why Leather Absorbs Contaminants

Leather is a natural, fibrous material. Its surface contains microscopic pores that can trap and absorb liquid or vapor-based chemicals. This process is accelerated if the leather is cut, scratched, or worn, as this exposes more of the absorbent inner material.

The Contrast with Rubber Boots

Rubber and other synthetic polymers are non-porous by design. Chemicals tend to remain on the surface, unable to penetrate the material itself. This makes the decontamination process—washing and neutralizing the contaminant—far more effective and reliable.

The Risk of Secondary Exposure

If a leather boot absorbs a hazardous substance, it can off-gas or transfer that chemical through contact later. This turns a piece of personal protective equipment (PPE) into a source of contamination, posing a risk to the firefighter, their colleagues, the fire apparatus, and even their home.

Understanding the Trade-offs and Consequences

Choosing PPE involves balancing protection, durability, and cost. In a hazmat context, the consequences of a material's limitations are magnified.

The Challenge of Effective Decontamination

You can wash a rubber boot and be highly confident it is clean. With leather, uncertainty always remains. It is nearly impossible to visually confirm that a chemical has been completely removed from its fibrous structure.

The High Cost of Replacement

Because of the difficulty in ensuring complete decontamination, the standard protocol for many departments is to condemn and replace leather boots after significant chemical exposure. This can lead to substantial and recurring equipment costs.

Compromised Structural Integrity

Beyond absorption, many chemicals can actively degrade the leather itself, weakening its structure and compromising its ability to protect against future physical or thermal threats. This damage is not always visible to the naked eye.

Making the Right Choice for Your Mission

Your operational needs should dictate your equipment choices. There is no single "best" boot, only the right boot for the specific hazard you are facing.

- If your primary focus is hazmat response: Rubber or synthetic polymer boots are the definitive choice for their superior chemical resistance and reliable decontamination.

- If your primary focus is structural firefighting with only incidental hazmat risk: Leather boots may be used, but you must implement extremely strict decontamination protocols and have a low threshold for condemning the boots after any suspected chemical exposure.

Ultimately, selecting the right PPE is an act of risk management designed to ensure your safety above all else.

Summary Table:

| Aspect | Leather Boots | Rubber Boots |

|---|---|---|

| Material Porosity | Porous, absorbs chemicals | Non-porous, chemicals stay on surface |

| Decontamination | Difficult, unreliable | Effective and reliable |

| Risk of Secondary Exposure | High, due to absorption | Low |

| Post-Exposure Protocol | Often requires condemnation/replacement | Can be safely cleaned and reused |

Ensure Your Team's Safety with the Right Protective Footwear

Choosing the correct boots for hazardous materials response is a critical safety decision. As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including advanced chemical-resistant rubber models designed for reliable protection and easy decontamination.

We can help you:

- Source the right gear: Get boots specifically engineered for hazmat scenarios.

- Manage costs: Benefit from our large-scale manufacturing efficiency.

- Protect your team: Equip them with footwear that minimizes secondary exposure risks.

Don't compromise on safety. Contact our experts today to discuss your specific needs and find the optimal footwear solution for your operations.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How does regular waterproofing maintenance benefit leather boots? Extend Lifespan & Performance

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What are some key features of recommended Western-style work boot models? Essential Safety & Comfort for Demanding Jobs

- What are the main benefits of PVC work boots? Lightweight, Waterproof & Affordable Footwear

- What is the Goodyear Welt construction method? Discover Unmatched Durability & Repairability

- What specific tests apply to proximity firefighting footwear? The 2 Critical Heat Tests Explained

- What are the advantages of pull on work boots for people with physical limitations? Boost Mobility & Independence