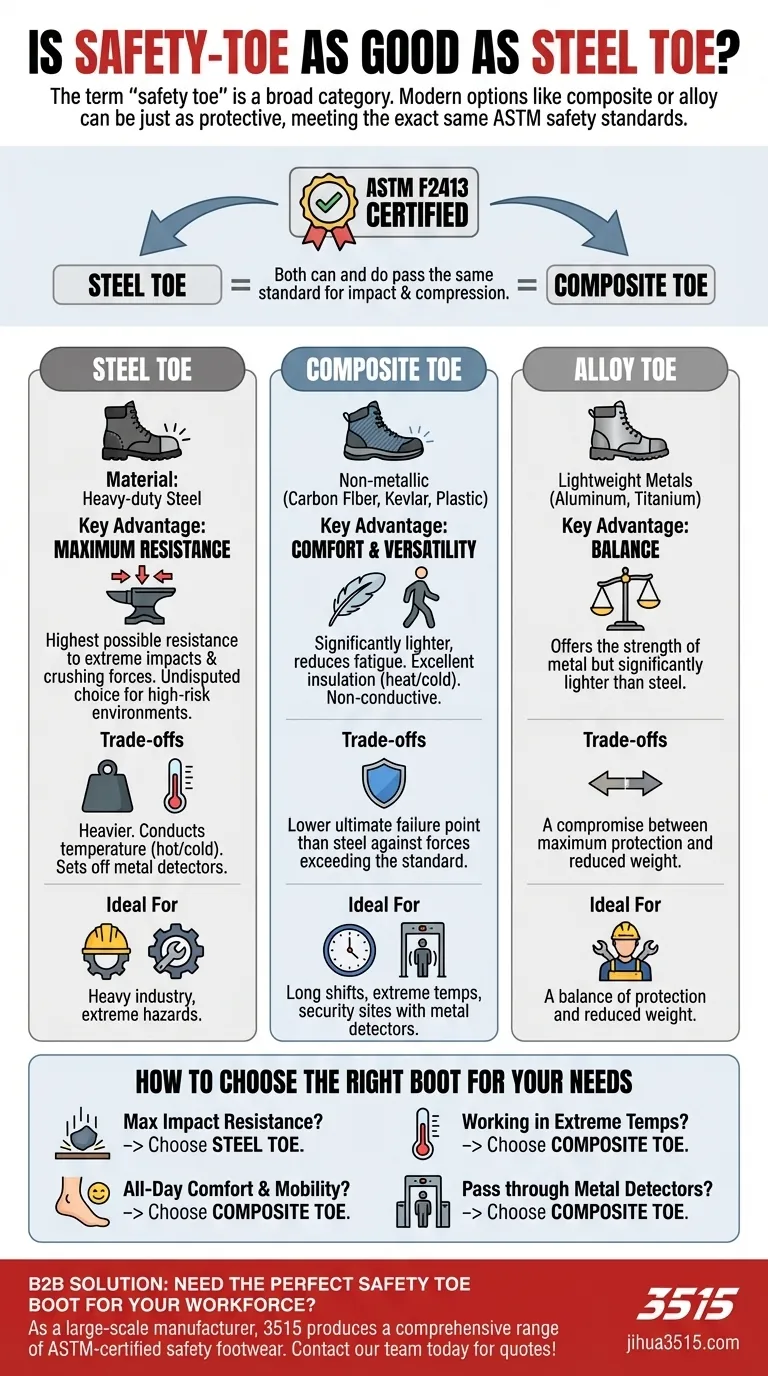

The term "safety toe" is a broad category, and a steel toe is simply one type of safety toe. When comparing steel to other modern options like composite or alloy toes, the answer is that non-steel options can be just as protective.

Modern composite and alloy toe boots are engineered to meet the exact same ASTM safety standards for impact and compression resistance as traditional steel toe boots. The key difference isn't in the certified level of protection, but in the material properties that make each type better suited for different work environments and user needs.

The question isn't whether one type of safety toe is universally "better," but which is the right tool for your specific job. Both steel and composite toes can meet the same official safety standards, but they achieve this with significant trade-offs in weight, conductivity, and comfort.

Deconstructing "Safety Toe": The Three Main Types

To make an informed decision, you must first understand the fundamental differences between the materials used in modern protective footwear.

Steel Toe

This is the traditional standard for safety footwear. The protective cap is made from heavy-duty steel, offering proven and reliable protection.

Steel toes are renowned for providing the highest possible resistance to extreme impacts and crushing forces.

Composite Toe

Composite toes are crafted from non-metallic materials like carbon fiber, fiberglass, plastic, or Kevlar. They are a lightweight, modern alternative to steel.

Their primary advantages are reduced weight, superior insulation against heat and cold, and the fact that they do not conduct electricity or trigger metal detectors.

Alloy Toe

Alloy toes are made from lightweight metals such as aluminum or titanium. They represent a middle ground between steel and composite.

These toes offer the strength of metal but are significantly lighter than steel, providing a compromise between maximum protection and reduced weight.

The Critical Benchmark: Understanding Safety Standards

The effectiveness of a safety toe isn't a matter of opinion; it's measured against rigorous, standardized tests.

What ASTM F2413 Means

In the United States, the primary standard for protective footwear is ASTM F2413. For a boot to be certified, its toe cap must pass specific tests for both impact and compression.

This standard ensures a baseline level of safety, regardless of the material used.

The Equalizer: Meeting the Same Standard

Crucially, both steel and composite toe boots can and do pass the same ASTM F2413 standard.

A certified composite toe boot has proven its ability to withstand the same level of impact (from a falling object) and compression (from a rolling object) as a certified steel toe boot.

Understanding the Trade-offs

While both meet the standard, their material differences create distinct advantages and disadvantages depending on your work conditions.

The Case for Steel: Maximum Resistance

Steel's core advantage is its sheer strength. While a composite toe can pass the standard, steel generally has a higher ultimate failure point against forces that exceed the testing requirements.

It remains the undisputed choice for environments with a high risk of exceptionally heavy falling objects or crushing hazards. However, it is heavier, conducts temperature, and will set off metal detectors.

The Case for Composite: Comfort and Versatility

The primary benefit of composite toes is user comfort and adaptability. They are significantly lighter, which reduces foot fatigue over long shifts.

Because they are non-metallic, they provide excellent insulation from extreme heat and cold. They also won't conduct electricity or cause issues at security checkpoints with metal detectors.

Common Pitfalls to Avoid

A common mistake is assuming that a heavier, stronger material is always the better choice.

Choosing a bulky steel toe for a job with high mobility requirements but low impact risk can lead to unnecessary fatigue. Conversely, prioritizing comfort over mandated safety protocols can have serious consequences. Always check if your job site has a specific requirement for steel toes.

How to Choose the Right Boot for Your Needs

Selecting the correct safety toe comes down to matching the boot's features to your daily tasks and environment.

- If your primary focus is maximum impact resistance: Choose steel toe. It offers the ultimate protection in hazardous environments with heavy machinery or falling debris.

- If your primary focus is all-day comfort and mobility: Choose composite toe. Its lighter weight significantly reduces fatigue over the course of a long workday.

- If your primary focus is working in extreme temperatures: Choose composite toe. It provides far better insulation against both hot and cold ground conditions.

- If you must pass through metal detectors frequently: Choose composite toe. It is non-metallic and will not trigger security sensors.

The best safety toe is the one that meets official standards while matching the specific demands of your job.

Summary Table:

| Safety Toe Type | Key Material | Primary Advantages | Ideal For |

|---|---|---|---|

| Steel Toe | Heavy-duty Steel | Maximum impact/crush resistance | Heavy industry, extreme hazards |

| Composite Toe | Carbon Fiber, Kevlar | Lightweight, non-conductive, insulated | Long shifts, extreme temps, security sites |

| Alloy Toe | Aluminum, Titanium | Strong but lighter than steel | A balance of protection and reduced weight |

Need the perfect safety toe boot for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Whether your team requires the ultimate protection of steel toe or the all-day comfort of composite, we have the production capabilities and expertise to meet your needs.

Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear

- How does the flexibility design of industrial safety shoes assist shipyard electricians? Boost Agility & Back Health

- What is the significance of composite or steel toe protection in work boots? Ensure Maximum Foot Safety & Comfort

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?