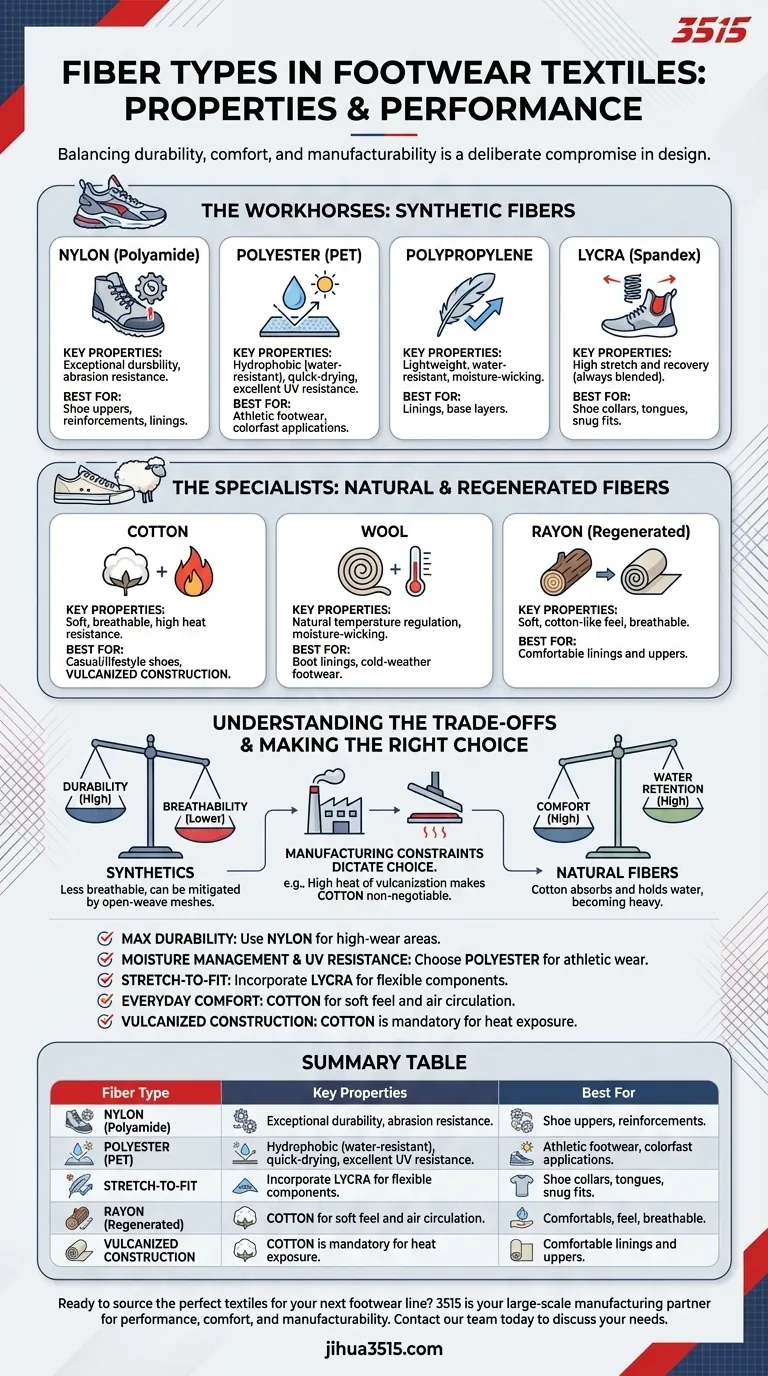

In footwear design, fiber selection is a foundational decision. The most common fibers used in footwear textiles are a blend of natural materials like cotton and wool, and versatile synthetics such as nylon, polyester, polypropylene, and lycra. Each is chosen for a specific set of properties, including its durability, stretch, moisture management, and resistance to environmental factors.

The optimal fiber for footwear is never a one-size-fits-all solution. The choice is a deliberate compromise, balancing the performance needs of the shoe, the comfort of the wearer, and the constraints of the manufacturing process.

The Workhorses: Synthetic Fibers

Synthetic fibers form the backbone of modern footwear due to their engineered performance characteristics, consistency, and durability. They can be precisely tailored to meet specific functional demands.

Nylon (Polyamide)

Nylon's defining characteristic is its exceptional durability and abrasion resistance. This toughness makes it a premier choice for shoe uppers, reinforcements, and linings that must withstand constant friction.

Polyester (PET)

Polyester is highly valued for its hydrophobic nature, meaning it resists water absorption and dries quickly. It also offers excellent resistance to UV degradation, which helps materials retain their color and strength after prolonged sun exposure.

Polypropylene

Like polyester, polypropylene is extremely lightweight and water-resistant. Its inability to absorb moisture makes it an excellent material for linings and base layers designed to wick sweat away from the skin.

Lycra (Spandex)

Lycra is used for one primary purpose: stretch and recovery. It is rarely used alone but is blended with other fibers to create stretchable textiles for shoe collars, tongues, and linings, ensuring a snug, adaptive fit.

The Specialists: Natural & Regenerated Fibers

Natural and regenerated fibers are chosen for their unique texture, comfort, and specific processing advantages that synthetics cannot replicate.

Cotton

Cotton is prized for its softness, breathability, and comfort against the skin. It is a staple in casual and lifestyle footwear.

Crucially, its high heat resistance makes cotton essential for vulcanized shoe construction. Synthetic fibers would melt during the high-temperature vulcanization process used to attach rubber soles.

Wool

Wool offers natural temperature regulation and moisture-wicking properties. It can absorb moisture vapor without feeling wet, making it a premium choice for linings in boots and cold-weather footwear.

Rayon

Rayon is a regenerated fiber, created from natural cellulose (typically wood pulp). It offers a soft, cotton-like feel and is often used in linings and uppers where a comfortable, breathable material is desired.

Understanding the Trade-offs

Selecting a fiber always involves balancing its strengths and weaknesses. There is no universally "best" material, only the most appropriate one for a specific application.

Synthetics: Durability vs. Breathability

While nylon and polyester offer superior durability, they are inherently less breathable than natural fibers. This can be mitigated through fabric construction (e.g., open-weave meshes), but the raw material itself is less permeable to air.

Natural Fibers: Comfort vs. Water Retention

Cotton’s key weakness in performance footwear is its tendency to absorb and hold water. Once wet, it becomes heavy and slow to dry, which can lead to discomfort. Wool manages moisture better but can be bulkier and more expensive.

Manufacturing Constraints Dictate Choice

The manufacturing process can be the single most important factor. As noted, the high heat of vulcanization makes cotton non-negotiable for certain shoe designs, regardless of the superior abrasion resistance offered by a synthetic like nylon.

Making the Right Choice for Your Goal

Your choice of fiber should be directly tied to the primary function of the footwear component you are designing.

- If your primary focus is maximum durability and abrasion resistance: Nylon is the superior choice, especially for high-wear areas like the shoe's upper.

- If your primary focus is colorfastness and moisture management: Polyester offers excellent UV resistance and quick-drying properties, making it ideal for athletic footwear.

- If your primary focus is a stretch-to-fit component: Lycra is the essential ingredient for creating flexible collars, linings, and bindings that conform to the foot.

- If your primary focus is comfort in casual wear: Cotton provides a soft feel and good air circulation for everyday, non-performance shoes.

- If you are designing for vulcanized construction: Cotton is mandatory for any textile component that will be exposed to the high heat of the vulcanization process.

Understanding these core fiber properties empowers you to deconstruct footwear design and make informed material decisions for any project.

Summary Table:

| Fiber Type | Key Properties | Best For Footwear Use |

|---|---|---|

| Nylon | Exceptional durability, abrasion resistance | Shoe uppers, reinforcements, high-wear areas |

| Polyester | Water-resistant, quick-drying, UV resistant | Athletic footwear, colorfast applications |

| Polypropylene | Lightweight, water-resistant, wicking | Linings, base layers for moisture management |

| Lycra (Spandex) | High stretch and recovery | Shoe collars, tongues, stretchable linings |

| Cotton | Soft, breathable, high heat resistance | Casual/lifestyle shoes, vulcanized construction |

| Wool | Temperature regulation, moisture-wicking | Boot linings, cold-weather footwear |

| Rayon | Soft, cotton-like feel, breathable | Comfortable linings and uppers |

Ready to source the perfect textiles for your next footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material science and production capabilities for all types of shoes and boots ensures your designs achieve the ideal balance of performance, comfort, and manufacturability. Contact our team today to discuss your material needs and production goals.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time