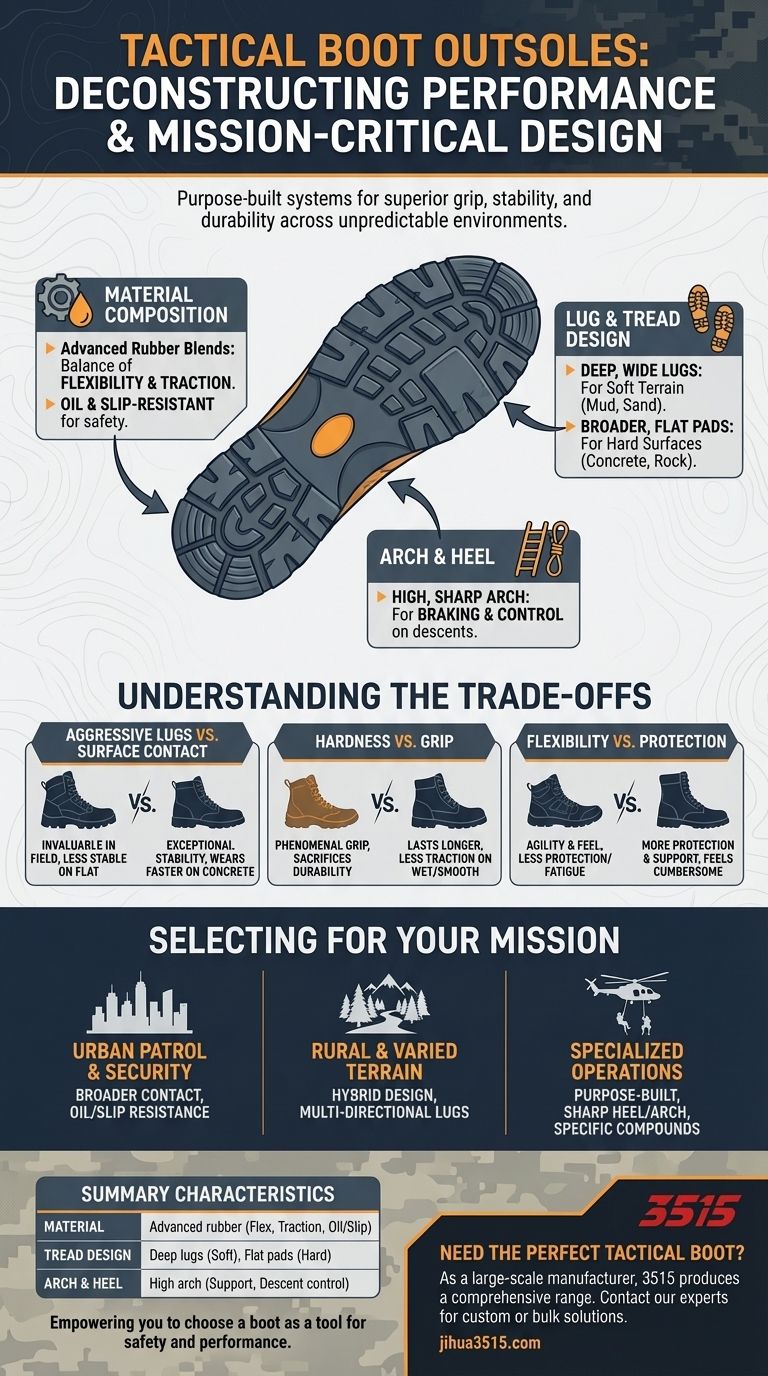

At its core, a tactical boot's outsole is a purpose-built system designed for superior grip, stability, and durability across unpredictable environments. It is almost always made from specialized rubber compounds and features a distinct tread pattern, or lug design, engineered to perform on specific types of terrain, from soft mud to hard, flat surfaces.

The ideal tactical outsole is not a single design, but a deliberate compromise. Its characteristics represent a calculated trade-off between grip, durability, and flexibility, engineered to give you a decisive advantage in a specific operational environment.

Deconstructing the Tactical Outsole

To understand its function, you must look at the outsole as a combination of three critical elements: the material it's made from, the pattern of its tread, and its structural shape.

The Foundation: Material Composition

The performance of any outsole begins with its material. Tactical boots exclusively use advanced rubber blends.

These compounds are formulated to provide a balance of flexibility for agility and traction on both wet and dry surfaces. Many are also oil-resistant and slip-resistant for safety in urban or industrial settings.

The Key to Grip: Lug and Tread Design

The most visible feature of an outsole is its tread pattern, which is composed of lugs. The design of these lugs dictates how the boot interacts with the ground.

Designs with deep, widely-spaced lugs are engineered for soft terrain like mud, sand, or gravel. The depth provides a strong bite, while the spacing allows mud to clear out so the tread doesn't get clogged.

Conversely, outsoles with broader, flatter pads create more surface contact. This design provides exceptional stability and grip on hard, flat surfaces like concrete, asphalt, or dry rock.

The Role of Arch and Heel

The outsole's profile is also a functional characteristic. Many tactical boots feature a high, sharp arch.

This design is not just for foot support; it's a tool for controlling speed during descents on ladders or ropes, allowing you to "brake" effectively, especially when carrying heavy gear.

Understanding the Trade-offs

Choosing an outsole means accepting a set of compromises. A design that excels in one area will inherently be weaker in another. Understanding this is key to selecting the right boot.

Aggressive Lugs vs. Surface Contact

An aggressive, deep-lugged outsole is invaluable in the field but can be a liability in an urban environment. The reduced surface contact can feel less stable on flat ground and will wear down much faster on concrete.

Hardness vs. Grip

The hardness of the rubber compound is a critical trade-off. Softer rubber provides phenomenal grip, especially on slick surfaces, but it sacrifices durability and wears out quickly.

A harder rubber compound will last significantly longer and resist abrasion, but it may provide less traction on wet or smooth terrain.

Flexibility vs. Protection

A highly flexible outsole enhances agility and gives you a better "feel" for the ground beneath you. However, this flexibility comes at the cost of protection from punctures and the foot fatigue that can occur on rough, uneven ground. A stiffer sole provides more protection and support but can feel cumbersome.

Selecting the Right Outsole for Your Mission

Your choice should be dictated entirely by your primary operational environment.

- If your primary focus is urban patrol or security: You need an outsole with broader surface contact for stability on concrete and effective oil- and slip-resistance.

- If your primary focus is rural or varied terrain: Look for a hybrid design with multi-directional lugs of moderate depth that can handle both soft ground and hard surfaces.

- If your primary focus is specialized operations: Seek a purpose-built design, such as one with a sharp heel and arch for rappelling or specific compounds for cold-weather grip.

Understanding the specific characteristics of an outsole empowers you to choose a boot that works as a tool, enhancing your safety and performance.

Summary Table:

| Characteristic | Purpose & Key Features |

|---|---|

| Material | Advanced rubber blends for flexibility, traction, oil/slip resistance. |

| Tread Design | Deep lugs for soft terrain; flat pads for hard surfaces. |

| Arch & Heel | High, sharp arch for support and controlled descent on ladders/ropes. |

| Trade-offs | Aggressive lugs vs. stability; soft rubber (grip) vs. hard rubber (durability). |

Need the Perfect Tactical Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical, safety, and outdoor footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, allowing us to engineer outsoles with the precise balance of grip, durability, and flexibility your mission requires.

Contact our experts today to discuss custom or bulk solutions tailored to your operational environment.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- What role does repairable design play in tactical boots? Extend Lifespan & Cut Total Ownership Costs

- How do high-performance tactical boots and training shoes support performance? Enhance Safety & Energy for Professionals

- What are the key features of classic jungle boots? Master the Design for Hot, Wet Environments

- What specific features are necessary for tactical boots used by emergency rescue personnel? Build Your Survival Gear

- How do you lace tactical boots properly? Secure Your Fit for Maximum Performance

- How does breathability contribute to the comfort of tactical boots? Prevent Blisters and Boost Performance

- What are the advanced features of tactical boots for waterproofing and moisture control?

- Why is it important to choose quality tactical boots? Ensure Peak Performance & Safety