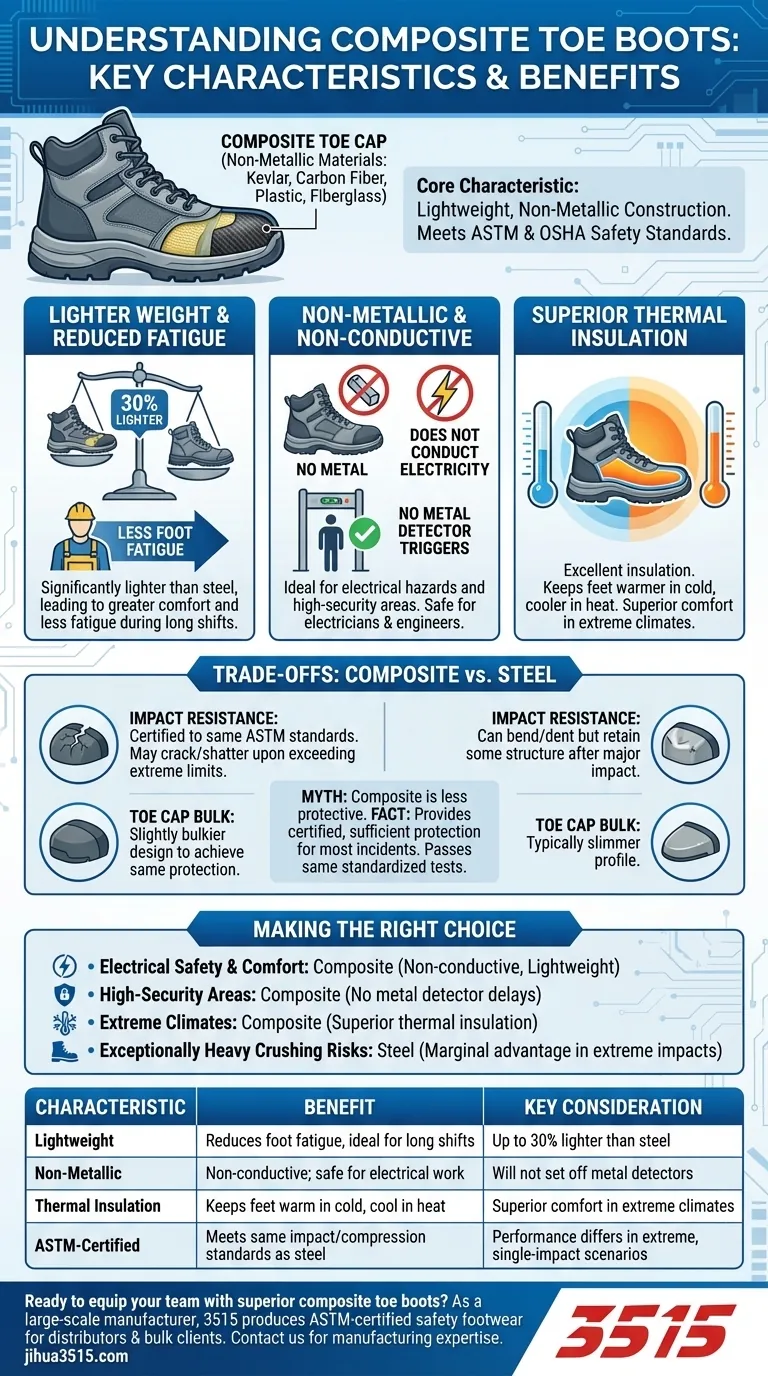

At their core, composite toe boots are safety footwear featuring a protective toe cap made from non-metallic materials like Kevlar, carbon fiber, plastic, or fiberglass. They are engineered to meet the same ASTM and OSHA safety standards for impact and compression resistance as traditional steel toe boots, but offer a distinct set of properties suitable for specific work environments.

The central characteristic of composite toe boots is their lightweight, non-metallic construction. This single feature is the source of all their primary advantages—electrical resistance, thermal insulation, and comfort—while also defining their main limitation in extreme impact scenarios.

The Defining Features of Composite Toe Boots

Composite toe boots have gained significant popularity by offering modern solutions to the drawbacks of traditional steel-toed footwear. Their characteristics are a direct result of the advanced materials used in their construction.

Lighter Weight and Reduced Fatigue

Composite materials are significantly lighter than steel, often resulting in a boot that is around 30% lighter than its steel-toed equivalent. This reduction in weight directly translates to less foot fatigue and greater comfort, especially for those who spend long hours on their feet or walk extensively throughout the day.

Non-Metallic and Non-Conductive

The complete absence of metal in the toe cap is a critical safety feature. Composite materials do not conduct electricity, making these boots an ideal choice for electricians, engineers, and anyone working in environments where electrical hazards are a primary concern. This non-metallic design also means they will not trigger metal detectors, a key benefit for workers in high-security facilities.

Superior Thermal Insulation

Unlike steel, which readily conducts ambient temperature, composite materials provide excellent insulation. In cold weather, they do not transfer the cold to your feet, keeping you warmer and more comfortable. Similarly, in extreme heat, they help insulate your feet from the high temperatures, making them a superior choice for outdoor work in varying climates.

Understanding the Trade-offs: Composite vs. Steel

While composite toe boots offer many modern advantages, it is crucial to understand their limitations, particularly when compared to steel. The choice between them is not about which is "better," but which is better suited for a specific job's risks.

Impact Resistance

Both composite and steel toe boots must meet the same minimum ASTM F2413 safety standards for impact and compression. However, after a single major impact, their behaviors differ. Steel can often bend or dent but retain some structural integrity, whereas a composite cap is more likely to crack or shatter upon experiencing a force that exceeds its structural limit. For this reason, steel is sometimes preferred in environments with a high risk of extremely heavy falling objects, like logging or heavy manufacturing.

Toe Cap Bulk

To achieve the same level of protection as steel, composite toe caps must be slightly bulkier. While manufacturers have made significant strides in design, this can result in a more bulbous toe box. This is rarely a functional issue but can be a factor in the overall fit and aesthetic of the boot.

The Myth of "Less Protection"

It is a common misconception that composite toes are inherently less protective. For the vast majority of workplace incidents, they provide certified and sufficient protection. They pass the same standardized tests as steel toes. The key difference lies in their performance beyond the certified limits, where steel has a slight edge in resisting catastrophic failure from a single, massive impact.

Making the Right Choice for Your Goal

Selecting the correct safety boot requires matching its characteristics to your daily work environment and potential hazards.

- If your primary focus is electrical safety and all-day comfort: Composite toe is the clear winner due to its non-conductive properties and lighter weight.

- If you work in high-security areas with metal detectors: Composite toe boots will prevent daily inconvenience and streamline your entry process.

- If you work outdoors in extreme hot or cold climates: The thermal insulation of a composite toe will provide a significant comfort advantage.

- If your job involves a high risk of exceptionally heavy crushing or falling objects: A steel toe boot may offer a marginal advantage in withstanding impacts that exceed standard safety ratings.

Ultimately, choosing a composite toe boot is a decision for modern, lightweight protection without sacrificing certified safety standards.

Summary Table:

| Characteristic | Benefit | Key Consideration |

|---|---|---|

| Lightweight | Reduces foot fatigue, ideal for long shifts | Up to 30% lighter than steel toe boots |

| Non-Metallic | Non-conductive; safe for electrical work | Will not set off metal detectors |

| Thermal Insulation | Keeps feet warm in cold, cool in heat | Superior comfort in extreme climates |

| ASTM-Certified | Meets same impact/compression standards as steel | Performance differs in extreme, single-impact scenarios |

Ready to equip your team with superior composite toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe boots, ensuring your workforce benefits from lightweight protection, electrical safety, and all-day comfort.

Contact 3515 today for a consultation and discover how our manufacturing expertise can meet your specific safety footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What safety features should be considered when choosing Wellington work boots? A Guide to Essential PPE

- Are Goodyear welted boots worth it? The Ultimate Guide to Lifelong Footwear

- What is the purpose of electric hazard boots? Essential Protection for Electrical Workers

- What should workers consider regarding warranties for Chemical Resistant boots? Ensure Genuine Protection

- What is the purpose of integrating an ultrasonic sensor module? Validate Energy Harvesting in Industrial Boots

- What are the functional benefits of lace-to-toe boots? Achieve a Superior, Customized Fit

- What additional safety features do structural firefighting boots provide? Beyond Heat Resistance

- What key functions do industrial safety boots with all-weather protection provide? Maximize Outdoor Operational Output