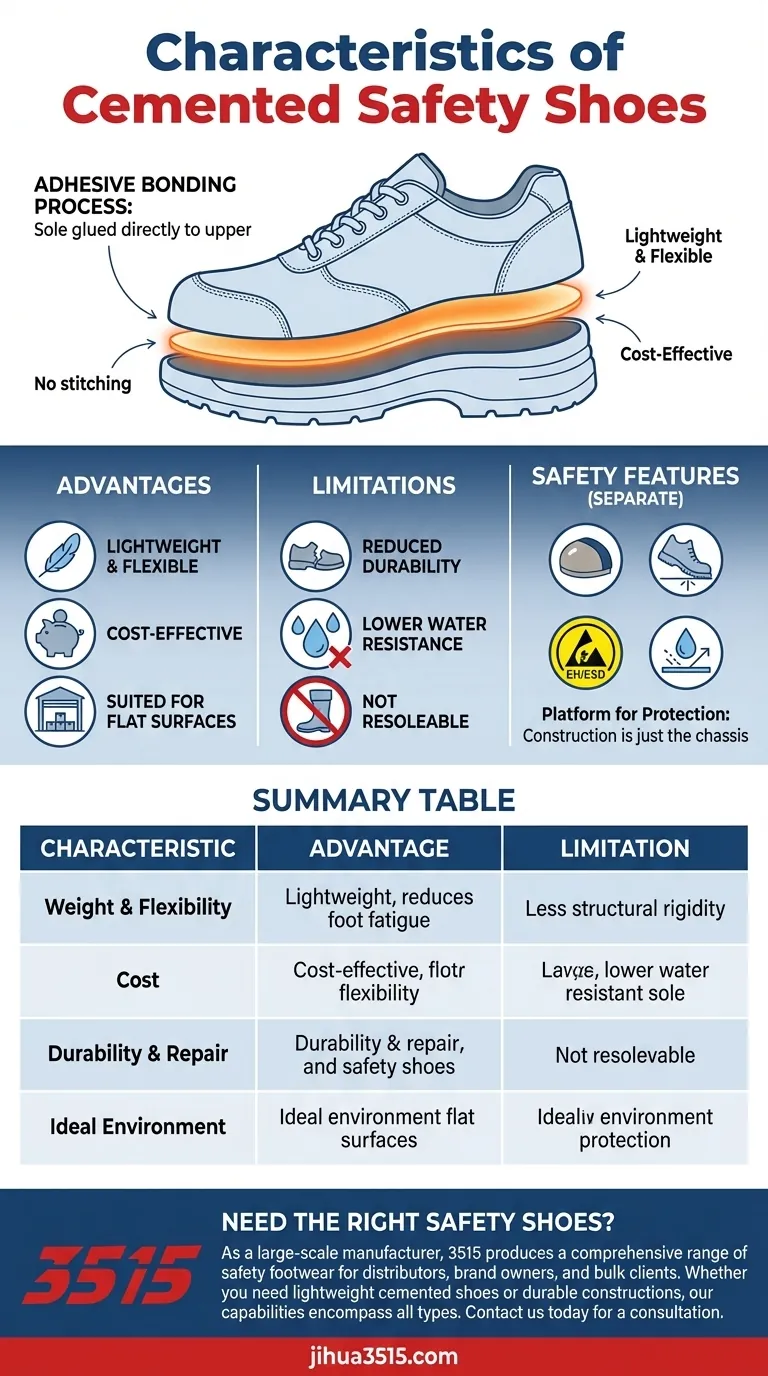

Cemented safety shoes are defined by their construction method: the sole is permanently glued directly to the upper of the shoe using a strong adhesive. This simple and fast manufacturing process results in a lightweight, flexible, and cost-effective safety shoe.

The core takeaway is that cement construction produces a light and affordable safety shoe ideal for less-demanding environments. However, this comes at the cost of the durability, water resistance, and repairability found in more robust construction methods.

The Core Construction: How It Works

This method is one of the most common in modern footwear manufacturing due to its speed and simplicity. Understanding the process reveals its inherent strengths and weaknesses.

The Adhesive Bonding Process

In cemented construction, the shoe's upper is shaped and then attached directly to the outsole using a powerful, durable adhesive. There is no stitching that connects the sole to the upper.

This method is also known as glued construction and is very similar to how most athletic sneakers are made.

Key Characteristics and Advantages

The direct-attachment process gives cemented safety shoes a distinct profile well-suited for specific applications.

Lightweight and Flexible

With no extra layers or welt stitching, the final product is significantly lighter and more flexible. This reduces foot fatigue over long shifts, especially for workers who are constantly in motion.

Cost-Effective Production

The speed and simplicity of the gluing process reduce manufacturing costs. This makes cemented safety shoes a highly economical option, particularly for large teams or those with budget constraints.

Suited for Flat, Predictable Surfaces

The combination of light weight and flexibility makes these shoes ideal for indoor environments like warehouses, light manufacturing facilities, and logistics centers where surfaces are generally flat and even.

Understanding the Trade-offs and Limitations

While cost-effective, the cemented method has clear limitations that make it unsuitable for heavy-duty or unpredictable work environments.

Reduced Durability

The adhesive bond is the primary point of failure. Under high stress, constant flexing, or exposure to certain chemicals or heat, the bond can weaken, causing the sole to separate from the upper.

Lower Water Resistance

A glued seam is not inherently as water-resistant as a stitched one. In consistently wet conditions, moisture can eventually compromise the adhesive and penetrate the shoe.

Typically Not Resoleable

Unlike shoes with a welted construction, cemented shoes cannot be resoled. Once the sole wears out or detaches, the entire shoe must be replaced, which can impact long-term cost-effectiveness.

Separating Construction from Safety Features

It is crucial to understand that "cemented" describes how the shoe is assembled, not its specific safety capabilities. The construction method is the foundation upon which other protective features are built.

A Platform for Protection

A cemented shoe can still be a high-performance piece of safety equipment. The construction provides the chassis, but the manufacturer can add numerous other features to meet specific workplace standards.

Common Add-on Features

A cemented safety shoe can be equipped with any combination of standard safety features, including:

- Steel or composite toe caps

- Puncture-resistant midsoles

- Slip-resistant outsoles

- Electrical Hazard (EH) or Electrostatic Dissipative (ESD) properties

- Metatarsal guards

- Waterproofing treatments and membranes

Making the Right Choice for Your Environment

Choosing the correct construction method is about aligning the shoe's characteristics with the demands of your job.

- If your primary focus is lightweight comfort and affordability for indoor or light-duty work: Cemented construction is an excellent and highly practical choice.

- If your primary focus is maximum durability and longevity in harsh, wet, or rugged outdoor conditions: You should explore more robust alternatives, such as Goodyear welted construction.

Ultimately, understanding the construction method empowers you to select a safety shoe that offers the right balance of performance, comfort, and value for your specific needs.

Summary Table:

| Characteristic | Advantage | Limitation |

|---|---|---|

| Weight & Flexibility | Lightweight, reduces foot fatigue | Less structural rigidity |

| Cost | Highly economical for large teams | Long-term value may be lower |

| Durability & Repair | Simple, fast manufacturing process | Not typically resoleable; bond can fail under stress |

| Ideal Environment | Indoor, flat surfaces (warehouses, light manufacturing) | Not suitable for harsh, wet, or rugged outdoor conditions |

Need the right safety shoes for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether you need lightweight cemented shoes for warehouse crews or more durable constructions for demanding environments, our production capabilities encompass all types of safety shoes and boots.

Contact us today for a consultation to find the perfect balance of safety, comfort, and value for your specific needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision