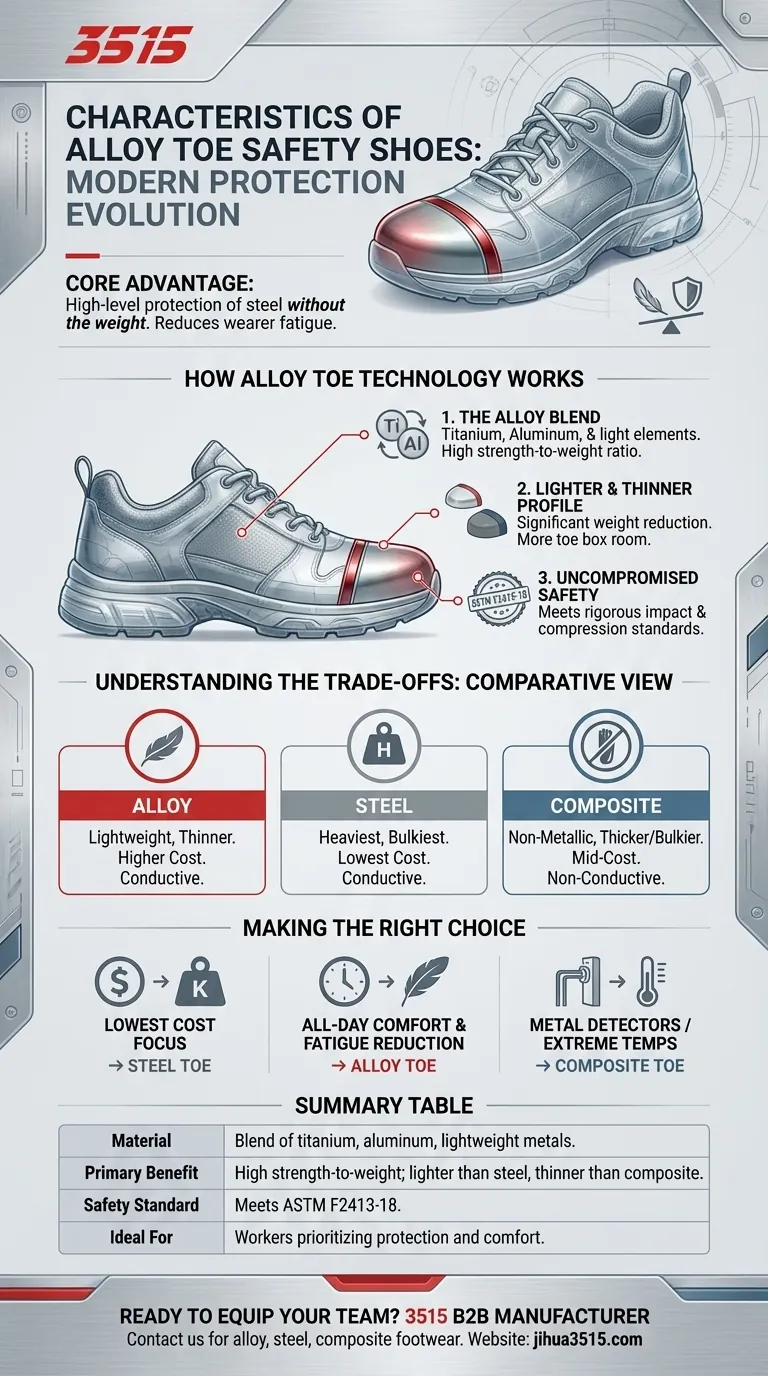

At their core, alloy toe safety shoes are a modern evolution in protective footwear, engineered from a blend of lightweight metals like titanium and aluminum. They provide robust impact and compression resistance that meets or exceeds industry safety standards, but in a significantly lighter package than traditional steel toes.

The central advantage of an alloy toe is its ability to deliver the high-level protection of steel without the associated weight. This results in a less bulky, more comfortable shoe that reduces wearer fatigue over a long day.

How Alloy Toe Technology Works

Alloy toe caps are the protective centerpiece of the shoe, designed to shield your feet from serious workplace hazards. Their characteristics are defined by the specific materials used and the engineering behind them.

The Alloy Material Blend

Alloy toes are crafted from a combination of metals, most commonly titanium, aluminum, and other light elements. This blend is specifically engineered to create a material with a very high strength-to-weight ratio. The result is a protective cap that is exceptionally strong yet surprisingly light.

A Lighter, Thinner Profile

The primary benefit of this advanced material is a significant reduction in weight compared to steel. This directly translates to less leg fatigue for the wearer over a long shift. Because the alloy is so strong, the protective cap can also be made thinner than composite alternatives, providing more room in the toe box for a more comfortable fit.

Uncompromised Safety Standards

Despite being lightweight, alloy toe footwear is not a "light-duty" option in terms of protection. These shoes are required to meet the same rigorous ASTM F2413-18 standards for impact and compression resistance as their steel and composite counterparts. This ensures they provide proven protection against falling objects and crushing forces.

Understanding the Trade-offs: Alloy vs. Other Materials

Choosing the right safety toe depends on understanding how alloy compares to the other primary options available: steel and composite.

Alloy vs. Steel

The classic trade-off here is weight versus cost. Steel toes are the traditional standard, offering maximum protection at a very affordable price point. However, they are the heaviest option. Alloy provides comparable protection but at a fraction of the weight, making it a superior choice for comfort, though it typically comes at a higher price.

Alloy vs. Composite

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. Their key advantage is that they don't conduct electricity, heat, or cold, and they won't set off metal detectors. However, to achieve the same strength rating as alloy or steel, composite caps must be thicker and bulkier, which can reduce space in the toe box.

The Cost and Availability Factor

Alloy toe shoes are generally more expensive than both steel and composite models. The advanced materials and manufacturing processes contribute to a higher retail price. They can also be slightly less common on the market, potentially offering fewer style choices compared to the widely available steel toe options.

Making the Right Choice for Your Goal

The best safety shoe is the one that aligns with your specific job requirements, environment, and personal comfort needs.

- If your primary focus is maximum protection at the lowest cost: Traditional steel toe remains the most practical and economical choice.

- If your primary focus is all-day comfort and reducing fatigue: Alloy toe provides steel-level protection with significantly less weight, making it an excellent investment for long shifts.

- If you pass through metal detectors or work in extreme temperatures: A non-metallic composite toe is the superior option for your needs.

Ultimately, choosing the right safety toe is about balancing the demands of protection, comfort, and your specific work environment.

Summary Table:

| Characteristic | Description |

|---|---|

| Material | Blend of titanium, aluminum, and other lightweight metals. |

| Primary Benefit | High strength-to-weight ratio; lighter than steel, thinner than composite. |

| Safety Standard | Meets ASTM F2413-18 for impact/compression resistance. |

| Ideal For | Workers prioritizing protection and all-day comfort over cost. |

Ready to Equip Your Team with High-Performance Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of alloy toe, steel toe, and composite safety shoes for distributors, brand owners, and bulk clients. We combine advanced materials with rigorous quality control to deliver durable, comfortable, and fully compliant footwear that protects your workforce and enhances productivity.

Contact us today to discuss your specific needs and request a quote for your next order!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the benefits of anti-slip outsoles and shock-absorbing features in welding shoes? Enhance Worker Endurance

- How do high-traction, slip-resistant outsoles on safety boots contribute to worker safety in mines? | Prevent Mining Falls

- Which sole material has excellent performance in chemical resistance? Choose the Right Protection for Your Worksite

- How does an Electric Moving Platform System simulate postural instability for balance studies? Master Footwear Safety

- What are the pros and cons of Moc Toe work shoes? A Guide to All-Day Comfort vs. Durability

- How do professional safety shoes contribute to postural stability during high-intensity logging in extreme conditions?

- What is the benefit of incorporating modern aesthetics and industrial design into safety shoes? Drive Compliance Now

- What is a significant advantage of composite safety shoes in workplaces with metal detectors? Unlock Uninterrupted Access and Efficiency