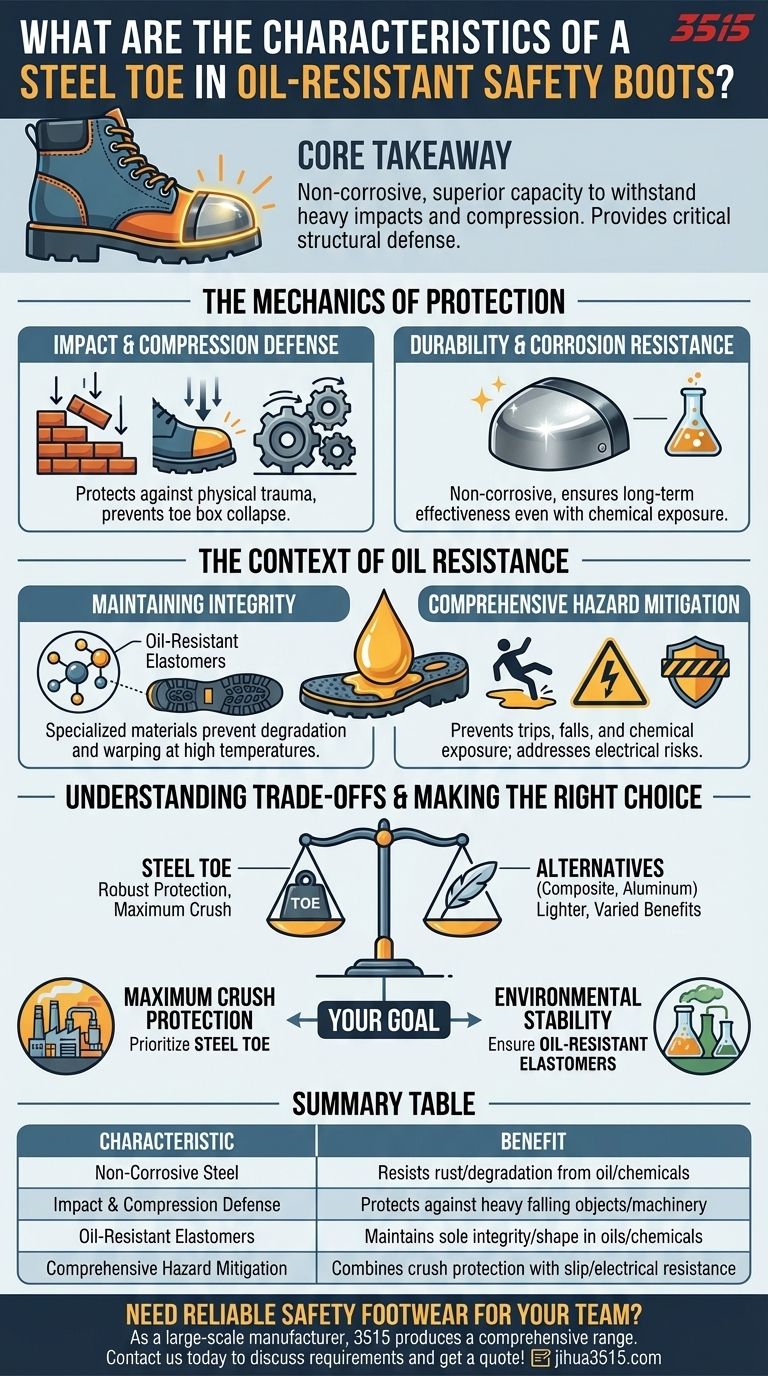

The defining characteristics of a steel toe in oil-resistant safety boots are its non-corrosive nature and its superior capacity to withstand heavy impacts and compression. This metallic cap serves as a rigid shield, integrated into footwear specifically engineered with elastomers to maintain structural integrity even when exposed to oil at elevated temperatures.

Core Takeaway: While the oil-resistant outsole prevents degradation and slips in hazardous chemical environments, the steel toe provides the critical structural defense needed to protect the wearer from crushing injuries and falling heavy objects.

The Mechanics of Protection

Impact and Compression Defense

The primary function of the steel toe is to provide a high level of protection against physical trauma.

In heavy industrial environments, this component acts as a barrier against falling objects (impact) and heavy rolling machinery (compression). It ensures that the toe box does not collapse under pressure, safeguarding the wearer's feet.

Durability and Corrosion Resistance

Steel toes used in these specific boots are manufactured to be non-corrosive.

This is essential because these boots are designed for environments involving oil and chemicals. The non-corrosive nature of the steel ensures the protective cap remains effective and does not rust or degrade over time, even if moisture or chemicals penetrate the outer leather.

The Context of Oil Resistance

Maintaining Integrity in Harsh Conditions

The "oil-resistant" aspect of these boots utilizes specialized oil-resistant elastomers.

Standard footwear often deteriorates quickly when exposed to oil, especially at high temperatures. These specialized materials ensure the boot maintains its functionality and structural shape, preventing the sole from warping or dissolving around the steel cap.

comprehensive Hazard Mitigation

Beyond physical impact, the design of these boots addresses broader safety concerns including electrical hazards and slips.

The construction helps prevent trips and falls in slick, oily environments. Additionally, the footwear provides a barrier against chemical exposure, ensuring that hazardous substances do not reach the skin.

Understanding the Trade-offs

Weighing Your Options

While steel toes offer robust protection, references indicate that other options exist, including wide toe, composite toe, and aluminum toe.

Each of these alternatives offers different benefits regarding protection levels and comfort. It is important to assess whether the maximum crush protection of steel is necessary for your specific role, or if a lighter alternative might suffice.

Balancing Protection with Fatigue

A key advantage of modern safety boots is the reduction of worker fatigue through comfortable footbeds.

However, the rigidity of a steel toe is a fixed factor. You must ensure the boot provides adequate interior cushioning and a proper fit to maintain that "all-day wear" comfort mentioned in boot designs, counteracting the hardness of the steel cap.

Making the Right Choice for Your Goal

When selecting safety footwear, you must match the toe cap characteristics to your specific environmental risks.

- If your primary focus is Maximum Crush Protection: Prioritize the steel toe for its proven ability to withstand heavy compression and impacts in industrial settings.

- If your primary focus is Environmental Stability: Ensure the boot specifies oil-resistant elastomers, particularly if you work around hot oils or chemicals that degrade standard rubber.

The ideal safety boot combines the impenetrable defense of a non-corrosive steel toe with the chemical stability of an oil-resistant sole.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Non-Corrosive Steel | Resists rust and degradation from oil, chemicals, and moisture. |

| Impact & Compression Defense | Protects against heavy falling objects and rolling machinery. |

| Oil-Resistant Elastomers | Maintains sole integrity and shape when exposed to oils and chemicals. |

| Comprehensive Hazard Mitigation | Combines crush protection with slip and electrical hazard resistance. |

Need Reliable Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant boots with non-corrosive steel toes, ensuring your workforce has the maximum protection and durability they need.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How are boots designed to meet the ASTM protective toe standard? A Guide to Impact & Compression Safety

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection

- What are the pros and cons of composite safety toes? Weighing Weight vs. Ultimate Protection

- What should safety shoes have? Essential Features for Ultimate Workplace Protection

- How do professional protective shoes help reduce lumbar load? Lower Spinal Stress with Superior Foot Stability

- What are the key safety considerations when choosing work shoes? A Guide to Matching Hazards & Footwear

- What professions require the use of safety shoes? Find the Right Footwear for Your Job's Hazards

- What are the responsibilities of employers regarding safety footwear under OSHA? Ensure Full Compliance & Protect Your Team