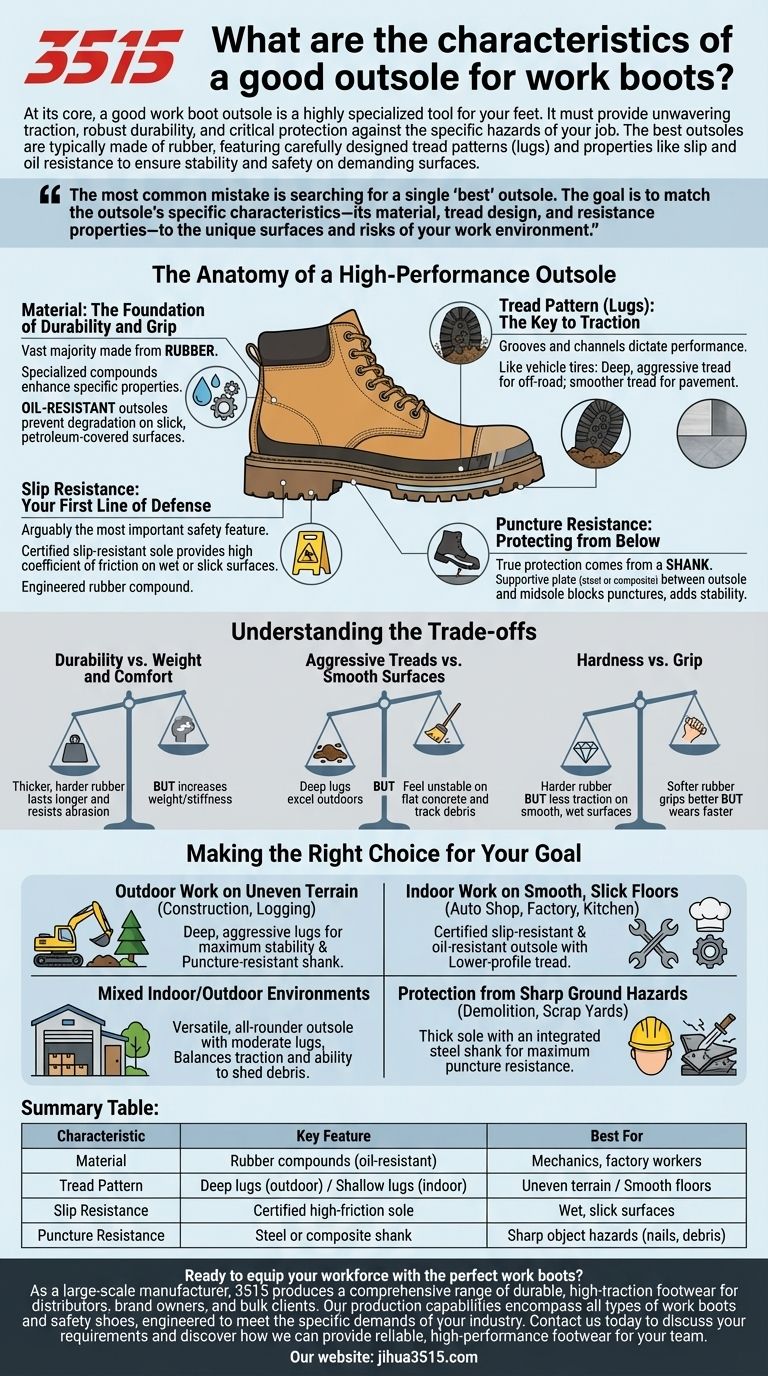

At its core, a good work boot outsole is a highly specialized tool for your feet. It must provide unwavering traction, robust durability, and critical protection against the specific hazards of your job. The best outsoles are typically made of rubber, featuring carefully designed tread patterns (lugs) and properties like slip and oil resistance to ensure stability and safety on demanding surfaces.

The most common mistake is searching for a single "best" outsole. The goal is to match the outsole's specific characteristics—its material, tread design, and resistance properties—to the unique surfaces and risks of your work environment.

The Anatomy of a High-Performance Outsole

A work boot's outsole is the critical point of contact between you and the ground. Its design is a balance of material science and functional engineering, where each component serves a distinct purpose.

Material: The Foundation of Durability and Grip

The vast majority of high-quality work boot outsoles are made from rubber. This material offers an excellent blend of flexibility and traction.

However, specialized rubber compounds are often used to enhance specific properties. An oil-resistant outsole, for example, is crucial for mechanics or factory workers, as it prevents the rubber from degrading and maintains grip on slick, petroleum-covered surfaces.

Tread Pattern (Lugs): The Key to Traction

The grooves and channels on the bottom of the boot are called lugs. Their design directly dictates the outsole's performance on different terrains.

Think of it like vehicle tires: a deep, aggressive tread is for off-road use, while a smoother tread is for pavement.

- Large, deep lugs are designed for stability on soft or uneven outdoor surfaces like dirt, mud, and gravel.

- Shallow, multi-directional lugs provide more surface contact and are better suited for smooth indoor floors, maximizing slip resistance.

Slip Resistance: Your First Line of Defense

This is arguably the most important safety feature of any outsole. A certified slip-resistant sole has been tested to provide a high coefficient of friction on wet or otherwise slick surfaces.

This feature is not just about tread design; it also involves the specific rubber compound used, which is engineered to grip smooth surfaces securely.

Puncture Resistance: Protecting from Below

While a thick outsole provides a basic buffer, true protection from nails and other sharp objects comes from a shank.

This supportive plate, often made of steel or a composite material, is embedded between the outsole and midsole. It not only blocks punctures but also adds crucial stability and support when climbing ladders or carrying heavy loads.

Understanding the Trade-offs

Choosing an outsole always involves balancing competing characteristics. Understanding these compromises is key to selecting the right tool for the job.

Durability vs. Weight and Comfort

A thicker, harder rubber outsole will last longer and resist abrasion better. However, this added durability comes at the cost of increased weight and stiffness, which can lead to foot fatigue over a long day.

Aggressive Treads vs. Smooth Surfaces

Deep lugs that excel in mud and dirt can become a liability indoors. They may feel unstable on flat concrete and can track significant amounts of debris, creating a separate hazard.

Hardness vs. Grip

A harder rubber compound offers superior longevity, but it may provide less traction on very smooth, wet surfaces compared to a softer compound. Softer rubber "grips" better but will wear down much faster.

Making the Right Choice for Your Goal

Select your outsole not by brand, but by the demands of your environment.

- If your primary focus is outdoor work on uneven terrain (construction, logging): You need deep, aggressive lugs for maximum stability and a puncture-resistant shank.

- If your primary focus is indoor work on smooth, slick floors (auto shop, factory, kitchen): Prioritize a certified slip-resistant and oil-resistant outsole with a lower-profile tread.

- If your primary focus is mixed indoor/outdoor environments: Look for a versatile, all-rounder outsole with moderate lugs that balances traction with the ability to shed debris.

- If your primary focus is protection from sharp ground hazards (demolition, scrap yards): A thick sole with an integrated steel shank for maximum puncture resistance is non-negotiable.

Ultimately, the best outsole is the one engineered to conquer the specific challenges you face every day.

Summary Table:

| Characteristic | Key Feature | Best For |

|---|---|---|

| Material | Rubber compounds (oil-resistant) | Mechanics, factory workers |

| Tread Pattern | Deep lugs (outdoor) / Shallow lugs (indoor) | Uneven terrain / Smooth floors |

| Slip Resistance | Certified high-friction sole | Wet, slick surfaces |

| Puncture Resistance | Steel or composite shank | Sharp object hazards (nails, debris) |

Ready to equip your workforce with the perfect work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-traction footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and safety shoes, engineered to meet the specific demands of your industry.

Contact us today to discuss your requirements and discover how we can provide reliable, high-performance footwear for your team.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Why is investing in quality PVC work boots important for workplace safety? Protect Your Workforce with 3515 Footwear

- What elements contribute to the support of a work boot? Discover the Key Components for All-Day Comfort

- In high-intensity sugarcane processing environments, what is the importance of industrial work boot durability? Safeguard Workers & Boost Efficiency

- What environmental conditions damage firefighter boots? The Hidden Cycle of Heat, Water & Chemicals

- What are the key benefits of wearing motorcycle boots? Essential Safety & Comfort for Riders

- How can breathability and comfort be ensured in work boots? A Guide to All-Day Foot Comfort

- How does the size of women's work boots compare to men's? The Key to a Safe, Anatomically Correct Fit

- Why is it important for women to wear work boots specifically designed for them? The Critical Role of Anatomical Fit