Finding the ideal work shoe requires aligning three distinct variables: your specific job hazards, your unique foot anatomy, and the shoe's structural composition. Rather than looking for a generic "best" brand, you must prioritize features like arch compatibility, safety certifications, and the specific materials used in the midsole and outsole to ensure long-term durability. By focusing on these technical specifications, you prevent injury and ensure the footwear serves your specific line of work.

True value in work footwear comes from selecting equipment that accommodates your foot's natural swelling throughout the day while rigorously meeting the friction and impact requirements of your specific workplace environment.

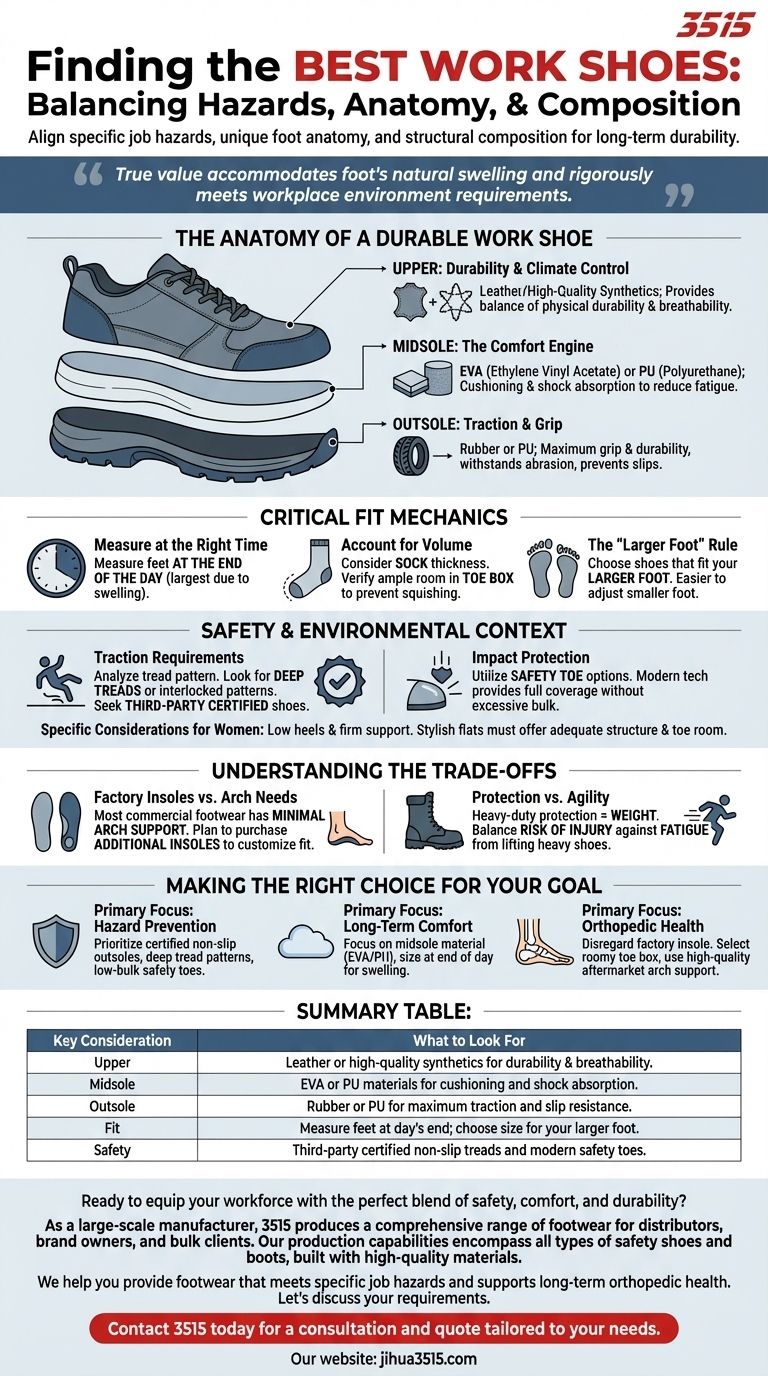

The Anatomy of a Durable Work Shoe

To evaluate quality, you must understand the three distinct components that make up a shoe. Each layer serves a different technical function.

The Upper: Durability and Climate Control

The Upper is the material that wraps around the top of the foot.

Look for leather or high-quality synthetics in this layer. These materials provide the necessary balance between physical durability and breathability.

The Midsole: The Comfort Engine

The Midsole is the layer between the inner sole and the outer tread. It is responsible for cushioning and shock absorption.

High-quality midsoles are typically made from EVA (Ethylene Vinyl Acetate) or PU (Polyurethane). This layer is critical for reducing fatigue during long shifts.

The Outsole: Traction and Grip

The Outsole is the bottom layer that makes direct contact with the ground.

For maximum grip and durability, prioritize outsoles made of rubber or PU. The material here dictates how well the shoe withstands abrasion and prevents slips.

Critical Fit Mechanics

A proper fit is not just about comfort; it is a safety requirement. Poorly fitted shoes lead to long-term foot problems and decreased productivity.

Measure at the Right Time

Never measure your feet in the morning.

Measure your feet at the end of the day when they are at their largest due to natural swelling.

Account for Volume

Length is not the only dimension that matters.

You must account for the thickness of the socks you intend to wear on the job. Additionally, verify there is ample room in the toe box to prevent squishing the front of the foot.

The "Larger Foot" Rule

Most people have slight size discrepancies between their left and right feet.

Always choose shoes that fit your larger foot. It is easier to adjust the fit on the smaller foot than to cramp the larger one.

Safety and Environmental Context

Your work environment dictates the specific safety features required. Modern technology has allowed for protection without the excessive bulk of traditional boots.

Traction Requirements

If you work in slippery environments, analyze the tread pattern.

Look for deep treads or interlocked patterns that channel liquid away. For verified safety, seek shoes tested and certified by third-party organizations.

Impact Protection

Foot injuries are a common workplace hazard.

Utilize safety toe options to curb hazards. Modern work shoes provide this full coverage without the heavy bulkiness associated with older styles.

Specific Considerations for Women

Standard sizing often fails to account for different foot shapes.

The best options for women feature low heels and firm support. Stylish flats can be a viable option if they provide adequate structural support and toe room.

Understanding the Trade-offs

No single shoe is perfect for every scenario. You must identify where manufacturers cut costs and where you might need to supplement the product.

Factory Insoles vs. Arch Needs

Most commercial footwear comes with minimal arch support.

If you have specific conditions like bunions or high arches, do not rely on the included insole. Plan to purchase additional insoles immediately to customize the fit to your arch height.

Protection vs. Agility

Heavy-duty protection often comes with weight.

While modern materials reduce bulk, a shoe with a steel toe and heavy rubber outsole will always be heavier than a soft-toe synthetic. You must balance the risk of injury against the fatigue caused by lifting a heavier shoe thousands of times a day.

Making the Right Choice for Your Goal

Select your footwear based on your primary daily challenge.

- If your primary focus is Hazard Prevention: Prioritize third-party certified non-slip outsoles with deep tread patterns and modern, low-bulk safety toes.

- If your primary focus is Long-Term Comfort: Focus on the midsole material (EVA/PU) and size the shoe at the end of the day to accommodate natural foot swelling.

- If your primary focus is Orthopedic Health: Disregard the factory insole and select a shoe with a roomy toe box that accommodates a high-quality aftermarket arch support.

Invest in the equipment that supports your physiology, because your productivity relies entirely on your mobility.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Upper | Leather or high-quality synthetics for durability & breathability. |

| Midsole | EVA or PU materials for cushioning and shock absorption. |

| Outsole | Rubber or PU for maximum traction and slip resistance. |

| Fit | Measure feet at day's end; choose size for your larger foot. |

| Safety | Third-party certified non-slip treads and modern safety toes. |

Ready to equip your workforce with the perfect blend of safety, comfort, and durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, built with high-quality materials like durable uppers, cushioned EVA/PU midsoles, and reliable rubber outsoles.

We help you provide footwear that meets specific job hazards and supports long-term orthopedic health. Let's discuss your requirements and find the ideal solution for your team.

Contact 3515 today for a consultation and get a quote tailored to your needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- Why is it important for women to wear work boots in the construction industry? Essential Safety & Performance

- Why is a melt-resistant sole important for wildland fire boots? Essential for Firefighter Safety & Traction

- Why is brand reputation important when selecting farming and gardening boots? Invest in Durability & Comfort

- What products can be used to waterproof leather boots? Choose the Right Protection for Your Gear

- What are some alternative footwear options to cowboy boots for farm work? Find the Perfect Fit for Your Farm

- What are the advantages of leather uppers in work boots? Unmatched Durability & Protection

- What product is recommended to protect leather boots from water saturation? Use a Wax-Based Conditioner

- What are electrical hazard (EH) rated work boots? Essential Secondary Protection for High-Risk Jobs