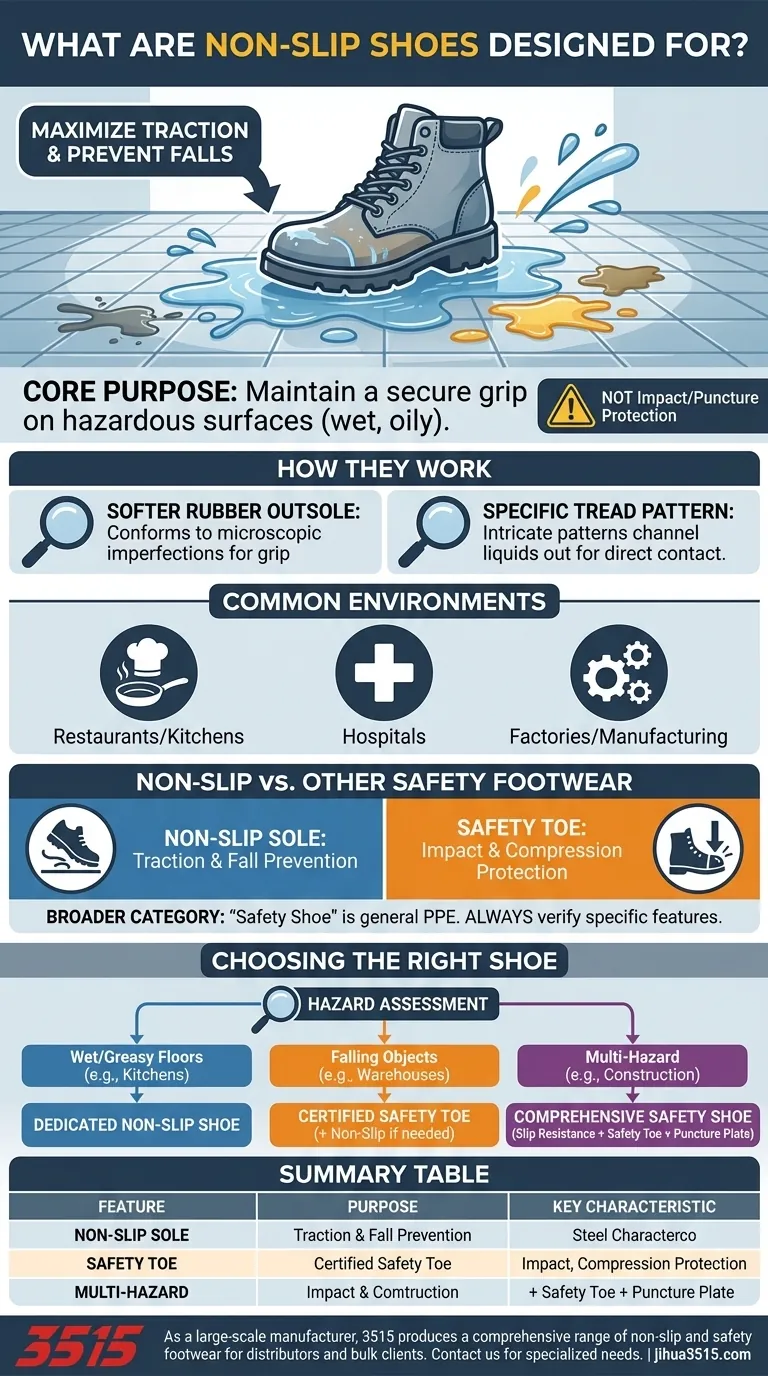

At their core, non-slip shoes are a highly specialized tool designed for a single, critical purpose: to maximize traction and prevent falls on slippery surfaces. They are engineered with specific materials and tread patterns to maintain a secure grip on floors that are wet, oily, or otherwise hazardous, making them essential safety equipment in many professional environments.

The term "non-slip" refers exclusively to a shoe's ability to grip the floor. It is crucial to understand that this feature is distinct from other safety functions, like impact or puncture protection, which address entirely different workplace hazards.

The Defining Feature: Mastering Traction

A shoe's slip resistance is not an accident; it's the result of intentional design choices in its materials and structure. Understanding these elements helps you identify a genuinely effective non-slip shoe.

How They Work

True non-slip shoes typically use a softer rubber outsole. This softer material can conform better to microscopic imperfections in the floor, increasing the total surface area for grip.

This is combined with a specific tread pattern. Unlike the deep lugs on a hiking boot designed for mud, non-slip treads are often composed of many small, intricate patterns that work to channel liquids out from under the shoe, allowing the sole to make direct contact with the surface.

Common Environments

These shoes are purpose-built for environments where floor hazards are a constant. This includes restaurants and commercial kitchens with frequent spills of water and grease, hospitals with polished, regularly cleaned floors, and factories or manufacturing plants where oils and other lubricants may be present.

Differentiating Non-Slip from Other Safety Footwear

The most common point of confusion is assuming all work shoes offer the same protections. This is a dangerous misconception. A shoe might be a "safety shoe" without being non-slip, and vice versa.

Non-Slip vs. Safety Toe

Slip resistance is about traction and preventing falls. A safety toe is about impact and compression protection. A shoe with a certified safety toe (often made of steel, composite, or alloy) is designed to protect your toes from being crushed by heavy, falling objects. A shoe can have one of these features, the other, or both.

The Broader Category of "Safety Shoes"

"Safety shoe" is a general term for any footwear classified as Personal Protective Equipment (PPE). This is a broad category that can include numerous features.

A comprehensive safety shoe might have a safety toe, a puncture-resistant plate in the sole, electrical hazard protection, and a slip-resistant outsole. However, you must never assume a shoe has any of these features unless it is explicitly stated by the manufacturer.

Understanding the Trade-offs and Terminology

The language used to market footwear can be misleading if you don't know what to look for. Your safety depends on looking past the marketing and focusing on the shoe's actual construction.

"Non-Slip" is a Marketing Term

The terms "non-slip" and "slip-resistant" are used interchangeably. Crucially, there is no official, regulated standard for what qualifies a shoe to carry this label.

This lack of regulation means the effectiveness can vary dramatically between brands. It falls on the user to verify the features that actually provide slip resistance.

The Misconception of Universal Protection

Buying a non-slip shoe will help protect you from falls, but it will offer zero protection from a dropped piece of equipment unless it is also rated for impact resistance with a safety toe.

Always perform a simple hazard assessment of your environment. What are the most likely sources of injury? Match the shoe's features to those specific risks.

How to Choose the Right Shoe for Your Environment

Your choice must be dictated by the specific hazards you face every day. Use this framework to select the right level of protection.

- If your primary focus is preventing falls on wet or greasy floors (e.g., a kitchen): Your absolute priority is a dedicated non-slip shoe with a soft rubber outsole and an effective, liquid-channeling tread pattern.

- If your primary focus is protection from falling objects (e.g., a warehouse): You must have a shoe with a certified safety toe, and you should verify if a non-slip sole is also required for your specific work area.

- If your primary focus is multi-hazard protection (e.g., construction or a factory): You need a comprehensive safety shoe that explicitly lists all protections you require, including slip resistance, a safety toe, and any other relevant certifications.

Assessing your specific workplace hazards is the only way to ensure your footwear provides complete and appropriate protection.

Summary Table:

| Feature | Purpose | Key Characteristic |

|---|---|---|

| Non-Slip Sole | Prevent slips and falls | Soft rubber outsole with intricate tread patterns |

| Safety Toe | Protect from impact/compression | Steel, composite, or alloy cap (separate from slip resistance) |

| Multi-Hazard Protection | Comprehensive workplace safety | Combines slip resistance, safety toe, puncture plate, etc. |

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip and safety footwear for distributors, brand owners, and bulk clients. Whether you need specialized kitchen shoes, hospital footwear, or multi-hazard industrial boots with certified safety features, we have the production capabilities and expertise to meet your demands. Contact us today to discuss your specific needs and discover how we can enhance your product line with reliable, high-quality safety shoes.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data