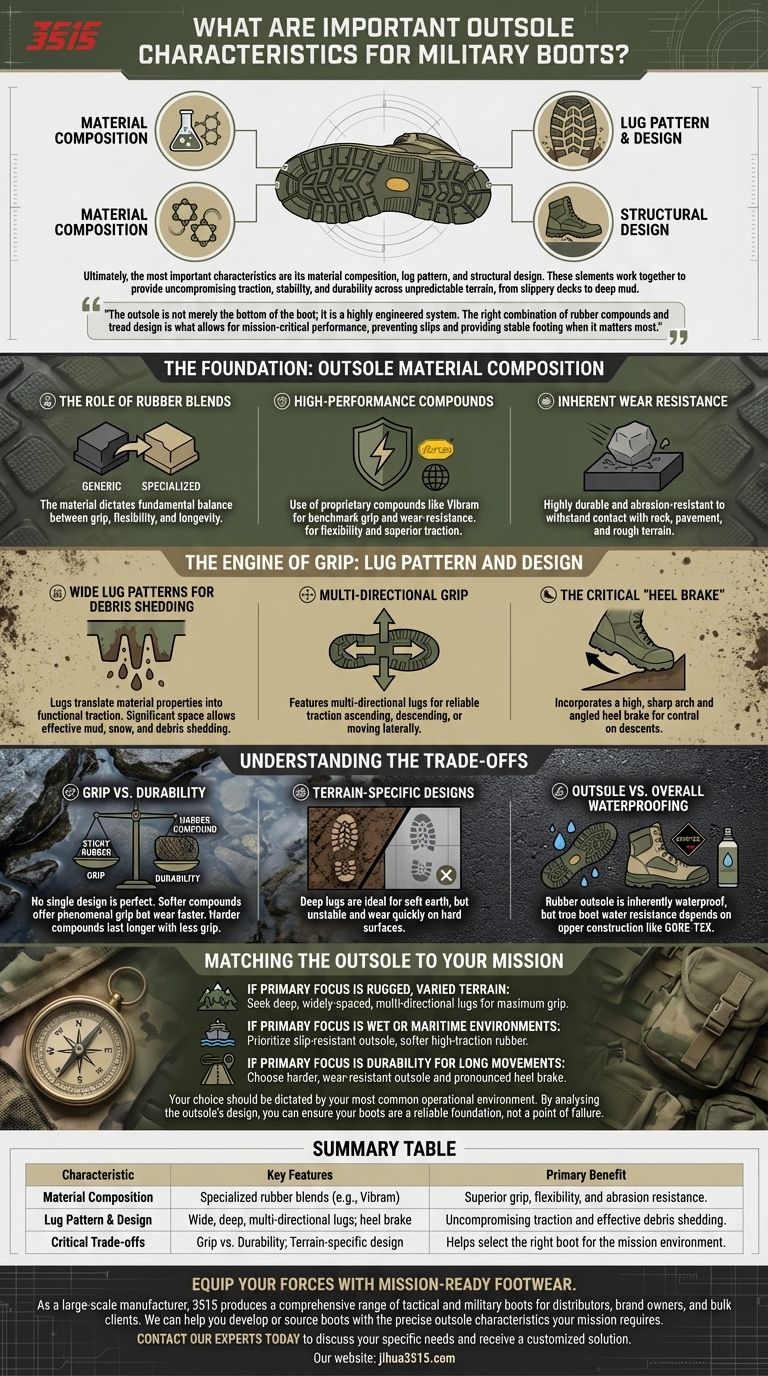

Ultimately, the most important characteristics of a military boot outsole are its material composition, lug pattern, and structural design. These elements work together to provide uncompromising traction, stability, and durability across unpredictable terrain, from slippery decks to deep mud.

The outsole is not merely the bottom of the boot; it is a highly engineered system. The right combination of rubber compounds and tread design is what allows for mission-critical performance, preventing slips and providing stable footing when it matters most.

The Foundation: Outsole Material Composition

The material used for an outsole dictates its fundamental balance between grip, flexibility, and longevity.

The Role of Rubber Blends

Modern military boot outsoles use specialized rubber blends, not just generic rubber. These compounds are formulated to remain flexible in various temperatures while offering superior traction on diverse surfaces.

High-Performance Compounds

Manufacturers often use proprietary or name-brand materials like Vibram. These are a benchmark for high-performance outsoles, renowned for their exceptional grip and wear-resistance under demanding conditions.

Inherent Wear Resistance

The material itself must be highly durable and abrasion-resistant. This ensures the outsole can withstand contact with rock, pavement, and rough terrain without degrading quickly, extending the operational life of the boot.

The Engine of Grip: Lug Pattern and Design

The physical shape and arrangement of the tread, or lugs, is what translates the material's properties into functional traction.

Wide Lug Patterns for Debris Shedding

A key feature is a wide, deep lug pattern. The significant space between lugs allows the boot to shed mud, snow, and debris effectively, preventing the sole from becoming clogged and slick.

Multi-Directional Grip

Effective outsoles feature multi-directional lugs. This design ensures reliable traction whether you are ascending, descending a steep grade, or moving laterally on an unstable surface.

The Critical "Heel Brake"

Many designs incorporate a high, sharp arch and a distinct heel that is cut at an angle. This acts as a "heel brake," digging into the ground to provide control and slow your descent, which is especially critical when carrying a heavy pack.

Understanding the Trade-offs

No single outsole design is perfect for every scenario. Understanding the compromises is key to selecting the right boot.

Grip vs. Durability

Softer, "stickier" rubber compounds offer phenomenal grip, especially on smooth, wet surfaces like rock or ship decks. However, this enhanced traction comes at the cost of faster wear. Harder compounds last much longer but may offer less grip.

Terrain-Specific Designs

An outsole with deep, aggressive lugs is ideal for soft earth and mud. On the other hand, these same lugs can feel unstable and wear down rapidly on concrete or asphalt, where a lower-profile design would perform better.

Outsole vs. Overall Waterproofing

While the rubber outsole is inherently waterproof, this does not make the entire boot waterproof. True water resistance depends on the boot's upper construction, such as a GORE-TEX liner. Sprays and waxes are maintenance items for the upper, not features of the outsole itself.

Matching the Outsole to Your Mission

Your choice should be dictated by your most common operational environment.

- If your primary focus is rugged, varied terrain: Seek a boot with deep, widely-spaced, and multi-directional lugs for maximum grip in mud and on uneven ground.

- If your primary focus is wet or maritime environments: Prioritize a slip-resistant outsole made from a softer, high-traction rubber compound.

- If your primary focus is durability for long movements: Choose a boot with a harder, wear-resistant outsole and a pronounced heel brake for stability on descents.

By analyzing the outsole's design, you can ensure your boots are a reliable foundation, not a point of failure.

Summary Table:

| Characteristic | Key Features | Primary Benefit |

|---|---|---|

| Material Composition | Specialized rubber blends (e.g., Vibram) | Superior grip, flexibility, and abrasion resistance. |

| Lug Pattern & Design | Wide, deep, multi-directional lugs; heel brake | Uncompromising traction and effective debris shedding. |

| Critical Trade-offs | Grip vs. Durability; Terrain-specific design | Helps select the right boot for the mission environment. |

Equip Your Forces with Mission-Ready Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical and military boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, high-performance footwear engineered for demanding conditions.

We can help you develop or source boots with the precise outsole characteristics your mission requires. Contact our experts today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

People Also Ask

- Do jungle boots provide enough ankle support? Understanding the Trade-offs for Hot, Wet Climates

- What are the primary uses of jump boots? Rigid Ankle Support for High-Impact Landings

- Why is it important for military personnel to wear properly fitted boots? Ensuring Mission Readiness and Safety

- How do military boots protect the feet from harm? An Inside Look at Protective Footwear Design

- Why are military camouflage boots versatile? The Ultimate All-Terrain Footwear Solution

- What is the primary material used for making durable and reliable military boots? A Guide to Modern Boot Construction

- What is the primary purpose of combat boots? Maximum Protection and Durability for Demanding Environments

- What are the benefits of using military camouflage boots? Unlock Tactical Performance & Durability