In short, eyelets are the holes or hardware in your hiking shoes through which you thread your laces. Beyond the simple punched holes you might see on sneakers, hiking footwear often uses specialized hardware like D-rings for easier tightening and speed hooks at the top for quickly securing or removing your shoes.

The design of a shoe's eyelets and lacing hardware is not a minor detail; it is a critical system that dictates how easily you can adjust the fit, how securely your foot is held on uneven terrain, and how durable the shoe will be over time.

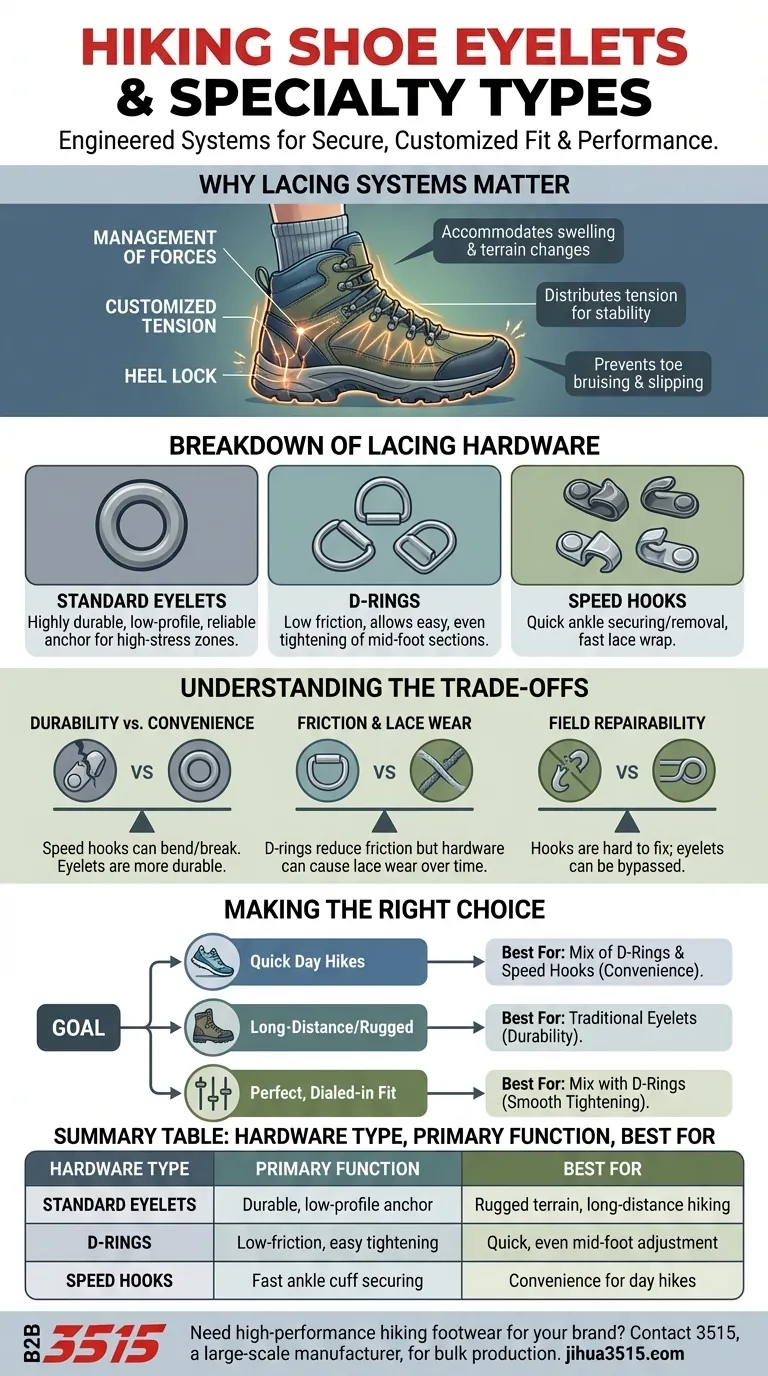

Why Your Lacing System is a Core Feature

The series of eyelets and hooks on your shoe is an engineered system designed to manage immense and varied forces. A proper lacing system is fundamental to performance and comfort on the trail.

The Goal: A Secure, Customized Fit

Your foot is not a static block. It swells on long hikes and changes its position as you move uphill or downhill. A good lacing system allows you to customize tension across different parts of your foot to accommodate these changes and prevent blisters or pressure points.

The Mechanism: Distributing Tension

Laces and eyelets work together to pull the upper part of the shoe snugly around your foot. This locks your heel into the back of the shoe, preventing the forward foot slide that causes bruised toes on descents, and provides stability across your midfoot.

A Breakdown of Lacing Hardware

Different types of hardware are used in different zones of the shoe to achieve specific goals, from durability at the bottom to speed at the top.

Standard Eyelets

These are typically reinforced holes, sometimes with a metal ring. They are highly durable and low-profile, offering a reliable anchor for laces in the lower part of the shoe that sees the most constant stress.

D-Rings

As the name suggests, these are D-shaped metal rings attached to the shoe's upper. Laces glide through them with less friction than standard eyelets, making it much easier to pull the laces and tighten the lower and mid-foot sections with a single, even pull.

Speed Hooks

Often found on the top two or three positions near the ankle, speed hooks are open-faced hooks instead of closed loops. This design allows you to quickly wrap the laces around them for final tightening, and just as quickly unhook them to create slack for taking the shoe off.

Understanding the Trade-offs

While specialty hardware adds convenience, it also introduces different points of potential failure compared to simple, reinforced eyelets.

Durability vs. Convenience

Speed hooks are the most common failure point in a lacing system. They can get bent or snagged on rocks and brush, and in some cases, can even break off entirely, compromising your ability to secure the ankle cuff of your shoe.

Friction and Lace Wear

D-rings significantly reduce the effort needed to tighten your shoes because they lower lace friction. While this is a major benefit, any lacing hardware can, over thousands of adjustments, contribute to wear and tear on your laces.

Field Repairability

A broken speed hook is difficult to repair on the trail. A blown-out traditional eyelet can often be bypassed by skipping it, but a broken D-ring might leave a loose piece of fabric that is harder to work around.

Making the Right Choice for Your Goal

The ideal lacing system depends on the type of hiking you do and what you value most in your footwear.

- If your primary focus is quick day hikes: A combination of D-rings and speed hooks offers maximum convenience for getting your shoes on and off quickly.

- If your primary focus is long-distance backpacking or rugged terrain: A system with more traditional, reinforced eyelets and fewer hooks provides greater durability and fewer potential failure points.

- If your primary focus is achieving a perfect, dialed-in fit: Look for shoes that use a mix of hardware, particularly D-rings or other low-friction guides in the mid-foot, to allow for smooth and even tightening.

Ultimately, understanding a shoe's lacing hardware empowers you to choose footwear that truly supports your specific needs on the trail.

Summary Table:

| Hardware Type | Primary Function | Best For |

|---|---|---|

| Standard Eyelets | Durable, low-profile lace anchor | Rugged terrain, long-distance hiking |

| D-Rings | Low-friction, easy tightening | Quick, even mid-foot adjustment |

| Speed Hooks | Fast ankle cuff securing/removal | Convenience for day hikes |

Need hiking footwear built for performance and durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of hiking shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, including models with specialized lacing systems designed for optimal fit and trail performance.

Let us help you equip your customers with the right gear. Contact our team today to discuss your footwear needs.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What should be considered when selecting hiking shoes or boots for backpacking? A Guide to Perfect Fit & Performance

- How does cushioning work in hiking shoes? The Science of Shock Absorption

- Why is proper footwear important for hiking? Essential Gear for Safety & Performance

- What is the difference between hiking boots and hunting boots? Choose the Right Boot for Your Mission

- What happens if moisture gets inside waterproof hiking boots? Trapped Water Leads to Blisters and Discomfort

- What are speed hooks, and how do they function? Get Your Boots On & Off Faster

- Why is toe protection important in hiking boots? Prevent Injury & Boost Durability

- Why is cushioning important in hiking or trekking shoes? Essential for Joint Protection & Energy Management