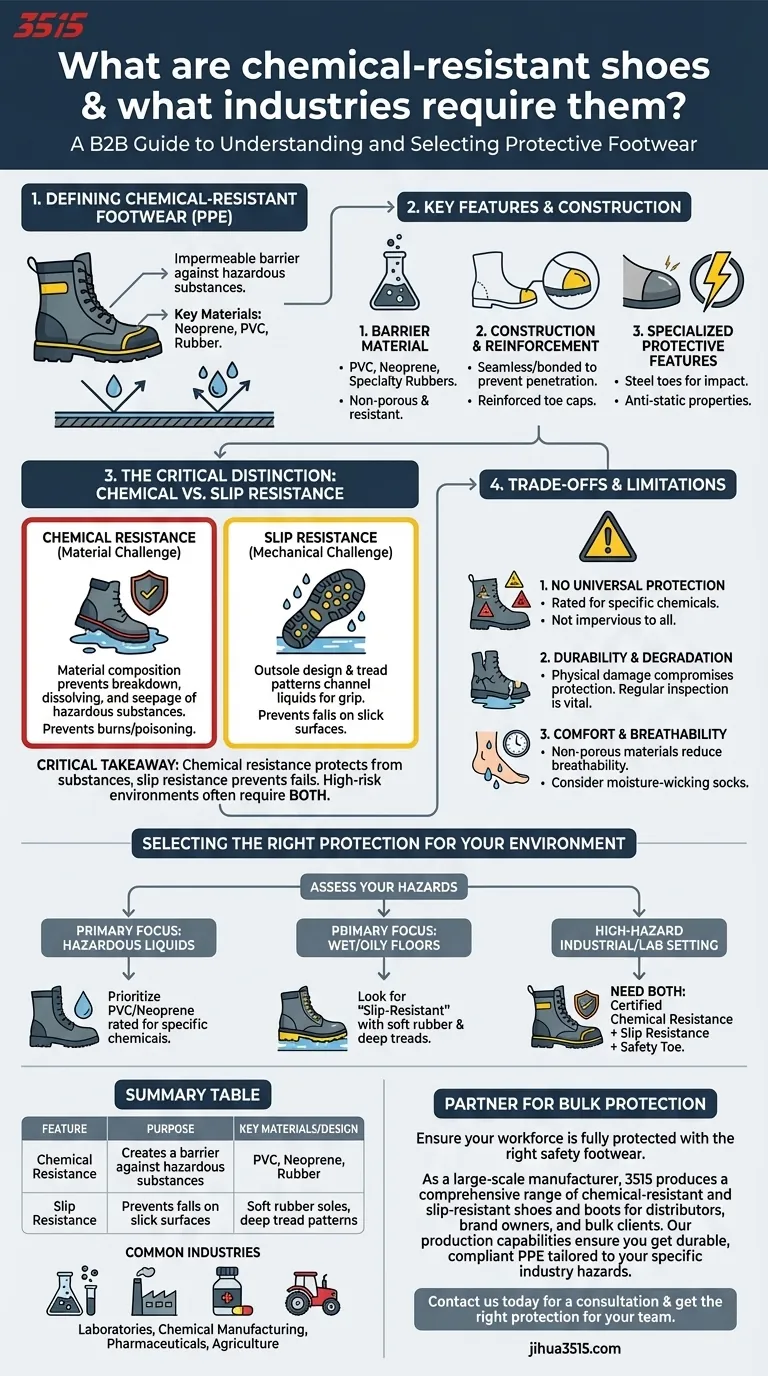

At its core, a chemical-resistant shoe is a specialized form of personal protective equipment (PPE) designed to create an impermeable barrier between your feet and hazardous substances. These shoes are constructed from materials like neoprene, PVC, or rubber that prevent chemical penetration and degradation. They are essential safety equipment in industries such as laboratories, chemical manufacturing plants, pharmaceuticals, and agriculture where chemical spills and exposure are a significant risk.

The most critical takeaway is that chemical resistance is a material property that protects you from hazardous substances, while slip resistance is a mechanical design feature that prevents falls. In many high-risk environments, you will require footwear that provides both.

What Defines Chemical-Resistant Footwear?

True chemical resistance is about more than just being waterproof. It involves specific materials and construction methods designed to withstand corrosive, toxic, or otherwise dangerous chemicals without failing.

The Barrier Material is Key

The primary feature of these shoes is the upper material itself. Unlike leather or fabric, materials like PVC (polyvinyl chloride), neoprene, and specialty rubbers are non-porous and do not degrade when exposed to specific classes of chemicals.

Construction and Reinforcement

Effective chemical-resistant footwear is often seamless or has bonded seams to eliminate points of failure where liquids could penetrate. Many models also include integrated reinforced toe caps and durable, thick soles for comprehensive protection from multiple hazards.

Specialized Protective Features

Depending on the work environment, these shoes may incorporate additional safety elements. This can include integrated steel toes for impact protection or anti-static properties to prevent sparks in volatile atmospheres.

The Critical Distinction: Chemical vs. Slip Resistance

Many hazardous environments that require chemical protection are also prone to slick surfaces. It is vital to understand that chemical resistance and slip resistance are two separate features that solve different problems.

Chemical Resistance: A Material Science Challenge

This feature is entirely about the shoe's material composition. The goal is to ensure the footwear does not break down, dissolve, or allow chemicals to seep through, which could cause severe burns or poisoning.

Slip Resistance: A Mechanical Design Challenge

Slip resistance is achieved through the shoe's outsole design. It relies on soft sole compounds like rubber or polyurethane and intricate tread patterns, such as hexagons, that are engineered to channel liquids away and maximize surface contact for superior grip.

Why Both Are Often Necessary

In a chemical plant or laboratory, a spill creates two immediate dangers: the chemical hazard itself and a slick, unsafe surface. Therefore, high-quality safety footwear for these roles must offer both a chemically inert barrier and a high-traction, slip-resistant sole.

Understanding the Trade-offs and Limitations

While essential, chemical-resistant footwear comes with considerations that you must factor into your selection. Being aware of these limitations is key to ensuring consistent safety.

No Universal Protection

The term "chemical-resistant" does not mean a shoe is impervious to all chemicals. A boot rated for strong acids may not hold up against potent solvents. Always match the shoe's material rating to the specific chemicals present in your workplace.

Durability and Degradation

Physical damage compromises protection. Any cut, puncture, or significant abrasion can create a pathway for chemicals to reach your skin, rendering the shoe unsafe. Regular inspection is non-negotiable.

Comfort and Breathability

The very properties that make these shoes protective—non-porous materials—also make them non-breathable. For long shifts, this can lead to discomfort, so proper sizing and moisture-wicking socks are important considerations.

Selecting the Right Protection for Your Environment

Choosing the correct footwear requires a clear assessment of your daily tasks and the specific hazards you face.

- If your primary focus is handling hazardous liquids: Prioritize footwear made from materials specifically rated for the chemicals you encounter, such as PVC or neoprene.

- If your primary focus is navigating wet or oily floors: Look for shoes explicitly labeled as "slip-resistant," with soft rubber outsoles and deep, effective tread patterns.

- If you work in a high-hazard industrial or lab setting: You almost certainly need a shoe that combines certified chemical resistance, slip resistance, and a reinforced safety toe for comprehensive protection.

Ultimately, understanding the distinct nature of each hazard is the first step toward selecting footwear that truly keeps you safe on the job.

Summary Table:

| Feature | Purpose | Key Materials/Design |

|---|---|---|

| Chemical Resistance | Creates a barrier against hazardous substances | PVC, Neoprene, Rubber |

| Slip Resistance | Prevents falls on slick surfaces | Soft rubber soles, deep tread patterns |

| Common Industries | Environments with chemical exposure risks | Laboratories, Chemical Manufacturing, Pharmaceuticals, Agriculture |

Ensure your workforce is fully protected with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of chemical-resistant and slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant PPE tailored to your specific industry hazards. Contact us today for a consultation and get the right protection for your team.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the core value of non-Newtonian fluid polymers in safety shoes? Unlock Dynamic Protection and Comfort

- How does high-retroreflective material improve footwear safety? Enhancing Visibility for Vulnerable Road Users

- What role do slip-resistant safety shoes play in high-risk environments? Essential Protection for Industrial Safety

- What is the most comfortable safety shoe? Find the Perfect Fit for All-Day Comfort

- What safety features should be considered in work shoes? Match the Right Protection to Your Job Hazards

- Why is it necessary to clean safety boots and protective clothing immediately? Prevent Deadly Chemical Exposure Now

- What are some real-world examples of safety footwear preventing injuries? Protect Your Workforce Effectively

- How does the Factorial Survey method function in safety footwear evaluation? Optimize Your Product Performance