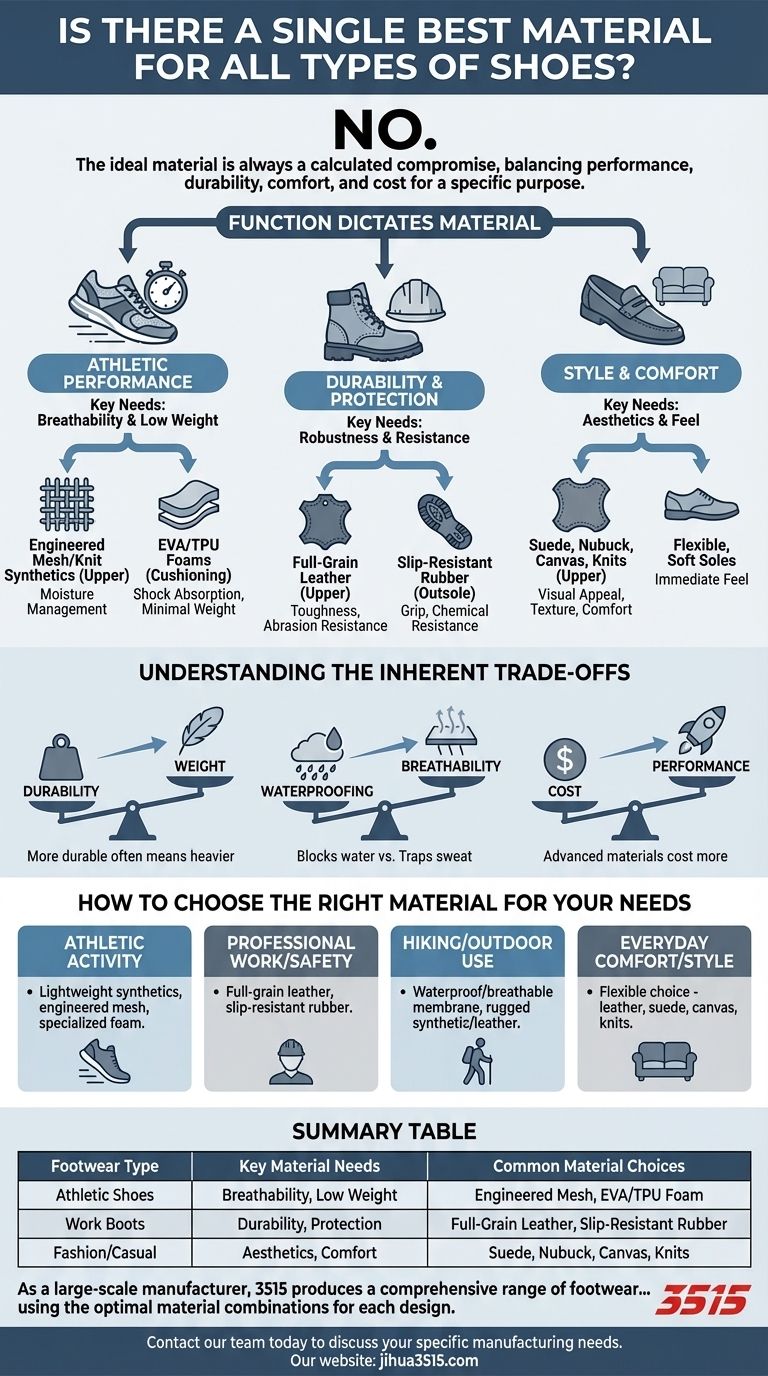

In short, no. There is no single best material for all shoes because the demands placed on a running shoe, a work boot, and a dress shoe are fundamentally different. The ideal material is always a calculated compromise, balancing performance, durability, comfort, and cost for a specific purpose.

The search for a single "best" shoe material is a misconception. The true goal of expert footwear design is to select an optimal combination of materials whose properties—like weight, flexibility, and abrasion resistance—are perfectly tailored to the shoe's intended function.

Why Function Dictates Material

A shoe is a piece of engineered equipment. Just as you wouldn't build a race car and a freight truck from the same metal, you cannot build all shoes from one material. The environment and the activity are the defining factors.

For Athletic Performance: Breathability and Low Weight

High-exertion activities like running generate significant heat and sweat. The priority is moisture management and minimal weight.

Materials like engineered mesh or knit synthetics are used for the upper. These provide structure while allowing air to circulate freely, keeping the foot cool and dry.

For cushioning, EVA (ethylene vinyl acetate) or TPU (thermoplastic polyurethane) foams are dominant. They offer exceptional shock absorption at a very low weight, reducing fatigue over long distances.

For Durability and Protection: Robustness and Resistance

Work boots are designed for safety and longevity in harsh environments. The primary needs are protection from impact, abrasion resistance, and support.

Full-grain leather remains a top choice for its incredible toughness and ability to mold to the foot over time. It resists cuts and scrapes far better than lightweight synthetics.

Outsoles are typically made of dense, slip-resistant rubber. This material provides superior grip on varied surfaces and withstands constant friction and exposure to chemicals.

For Style and Comfort: Aesthetics and Feel

In fashion and casual footwear, the primary drivers are visual appeal and immediate comfort. Technical performance is a secondary concern.

Premium materials like suede, nubuck, or patent leather are chosen for their texture and finish. Canvas and other textiles offer a wide range of colors and patterns.

The focus is on how the material looks and feels, with less emphasis on its ability to handle extreme stress or weather.

Understanding the Inherent Trade-offs

Every material choice is a balance of competing properties. Improving one characteristic often means compromising on another. This is the central challenge of footwear design.

Durability vs. Weight

There is almost always a direct trade-off between how long a material lasts and how much it weighs.

A thick leather work boot is incredibly durable but would be far too heavy and cumbersome for a marathon. Conversely, an ultralight racing flat's foam sole provides peak performance but may wear out after just a few hundred miles.

Waterproofing vs. Breathability

Keeping water out is often at odds with letting sweat escape. This is a critical challenge for outdoor and hiking footwear.

A completely waterproof material like rubber is also completely non-breathable. This traps sweat, leading to discomfort and blisters. Materials like Gore-Tex are engineered with microscopic pores that are small enough to block water droplets but large enough to let water vapor (sweat) out—a complex and costly compromise.

Cost vs. Performance

The most advanced materials come at a higher price. This is a simple manufacturing reality.

High-rebound "super foams" and carbon fiber plates found in elite running shoes drastically increase the cost. For everyday shoes, designers select more cost-effective synthetics and rubbers that provide reliable, if not record-breaking, performance.

How to Choose the Right Material for Your Needs

Instead of searching for one "best" material, focus on the material best suited for your specific goal.

- If your primary focus is athletic activity: Prioritize lightweight synthetics, engineered mesh for breathability, and specialized foam midsoles for cushioning.

- If your primary focus is professional work or safety: Look for full-grain leather for durability and protection, paired with slip-resistant rubber outsoles.

- If your primary focus is hiking or outdoor use: Seek out footwear with a waterproof yet breathable membrane combined with rugged synthetic or leather uppers.

- If your primary focus is everyday comfort and style: You have the most flexibility, from classic leather and suede to versatile canvas and modern knits that match your aesthetic.

Understanding the purpose behind the material empowers you to choose footwear that truly serves its function.

Summary Table:

| Footwear Type | Key Material Needs | Common Material Choices |

|---|---|---|

| Athletic Shoes | Breathability, Low Weight | Engineered Mesh, EVA/TPU Foam |

| Work Boots | Durability, Protection | Full-Grain Leather, Slip-Resistant Rubber |

| Fashion/Casual | Aesthetics, Comfort | Suede, Nubuck, Canvas, Knits |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, using the optimal material combinations for each design. Whether you need high-performance athletic footwear, durable work boots, or stylish casual shoes, we can deliver quality and value at scale. Contact our team today to discuss your specific manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What role do high-capacity wall-mounted exhaust fans play in BTEX mitigation? Ensure Worker Safety in Footwear Factories

- What are the advantages of leather soles? Discover the Hallmarks of Timeless Footwear

- What technical advantages does fiber regeneration technology offer? Achieve Virgin-Quality Circularity in Textiles

- What is the value of efficient fabric recycling equipment? Build a Circular Supply Chain for Sustainable Footwear

- How does high-precision spectrophotometry evaluate footwear fabric dyeing? Achieve Science-Based Color Consistency

- Why is it necessary for a footwear manufacturer to maintain a production range from safety shoes to formal dress shoes?

- What are the core functions of the portable microprocessor in gait analysis? Unlock Real-Time Dynamic Biomechanics

- How do integrated PPG sensors in footwear contribute to early warning systems in orthopedic trauma care?