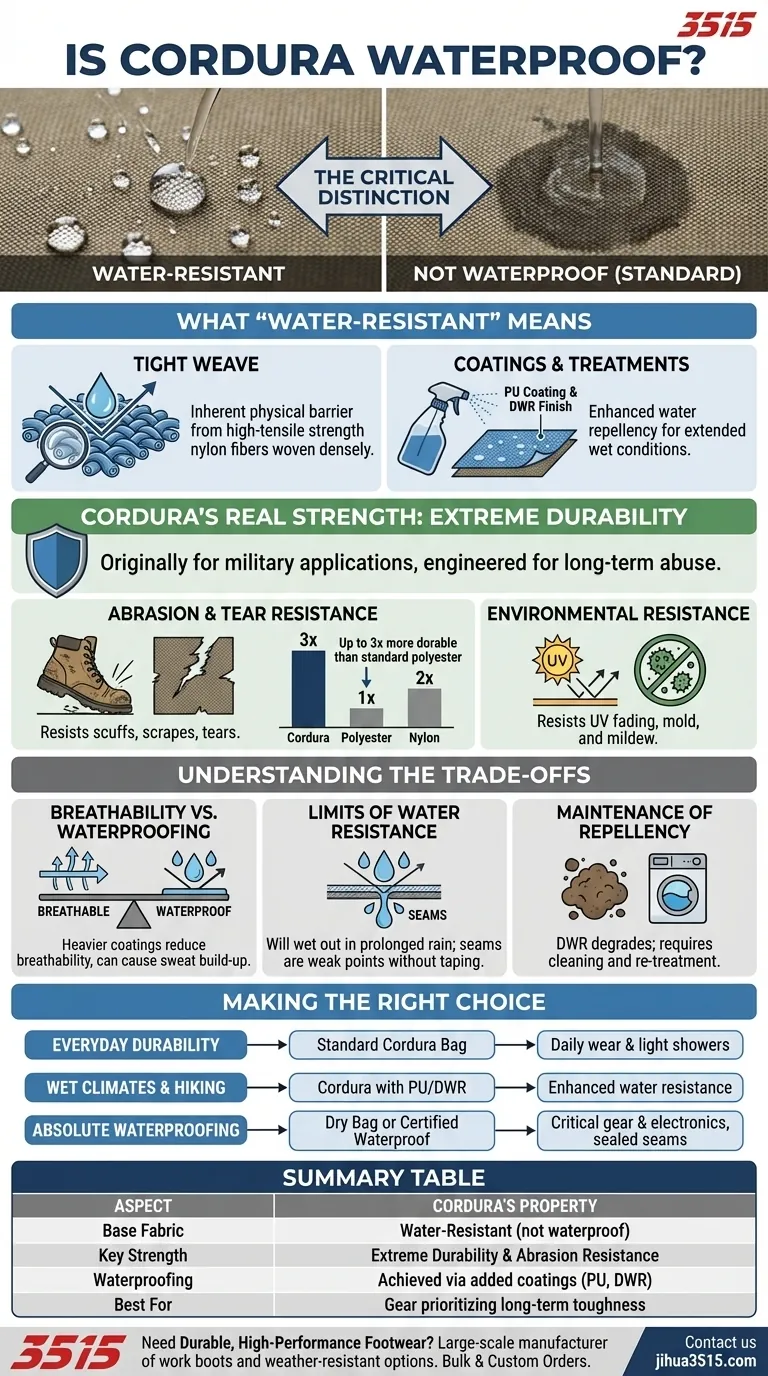

In its standard form, Cordura fabric is not waterproof. It is, however, highly water-resistant. This is a critical distinction that depends on the fabric's construction and any additional treatments applied by the product manufacturer. Due to its exceptionally tight weave, Cordura will cause water to bead up and roll off the surface, effectively protecting against light rain and brief exposure to moisture.

The core issue is not the Cordura fabric itself, but how it's treated. Base Cordura offers excellent water resistance, but achieving true waterproof performance requires additional coatings or linings that are applied at the product level.

What "Water-Resistant" Actually Means

To make an informed decision, you must understand the difference between a fabric that resists water and one that is truly waterproof. They serve different purposes and offer different levels of protection.

The Role of the Tight Weave

Cordura's inherent water resistance comes from its construction. It is made from high-tensile strength nylon fibers that are woven together very densely. This tight weave creates a physical barrier that is difficult for water droplets to penetrate quickly.

The Impact of Coatings and Treatments

Many manufacturers enhance Cordura's capabilities by adding a coating to the fabric. A polyurethane (PU) coating or a Durable Water Repellent (DWR) finish is often applied to repel water more effectively, making the product suitable for extended use in wet environments.

Cordura’s Real Strength: Extreme Durability

While its water resistance is notable, the primary reason designers choose Cordura is for its legendary toughness and longevity. Its original purpose was for military applications, which tells you everything you need to know about its ability to withstand abuse.

Resistance to Abrasions and Tears

Cordura fabric is engineered to endure long-term wear. Its high-strength fiber structure makes it exceptionally resistant to the scuffs, scrapes, and tears that would destroy lesser materials.

In standardized testing, Cordura has proven to be up to 3 times more durable than standard polyester and 2 times more durable than standard nylon.

Resistance to Environmental Factors

Beyond physical damage, Cordura is also built to resist environmental decay. The fabric is resistant to damage from UV fading as well as performance degradation from mold and mildew.

Understanding the Trade-offs

No material is perfect for every application. While Cordura is a top-tier performance fabric, its features come with inherent trade-offs you should be aware of.

Breathability vs. Waterproofing

The heavier the waterproof coating applied to Cordura, the less breathable the fabric becomes. For a backpack, this is not an issue. For apparel like a jacket, a heavy coating can trap sweat and moisture, making it feel clammy during high-exertion activities.

The Limits of Water Resistance

Even with a DWR coating, Cordura will eventually "wet out" or become saturated during prolonged downpours or submersion. Furthermore, seams are a weak point. Without taped or sealed seams, water will penetrate the stitching on any bag or garment, regardless of the fabric's properties.

Maintenance of Repellency

DWR coatings degrade over time due to dirt, abrasion, and washing. To maintain performance, products with these coatings need to be cleaned and periodically retreated with a spray-on or wash-in DWR product.

Making the Right Choice for Your Goal

You must evaluate a Cordura product based on its specific features, not just the fabric name alone. Check the product specifications for any mention of waterproof coatings or sealed seams.

- If your primary focus is everyday durability: A standard Cordura bag or pack will offer more than enough protection from daily wear and light showers.

- If your primary focus is hiking or travel in wet climates: Seek out products that explicitly state they have a PU or DWR coating for enhanced water resistance.

- If your primary focus is absolute waterproof protection for electronics or critical gear: Do not rely on a Cordura bag alone. Use a dedicated dry bag or look for products with a certified waterproof rating and sealed seams.

Ultimately, choosing Cordura means prioritizing exceptional durability, with its water resistance serving as a significant and valuable secondary benefit.

Summary Table:

| Aspect | Cordura's Property |

|---|---|

| Base Fabric | Water-Resistant (not waterproof) |

| Key Strength | Extreme Durability & Abrasion Resistance |

| Waterproofing | Achieved via added coatings (e.g., PU, DWR) |

| Best For | Gear prioritizing long-term toughness |

Need Durable, High-Performance Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear built for demanding conditions. We understand the balance between durability, water resistance, and comfort.

We can help you with:

- Durable Work Boots: Ideal for construction, logistics, and outdoor work.

- Weather-Resistant Footwear: Options with enhanced treatments for various environments.

- Bulk & Custom Orders: Tailored solutions for distributors, brand owners, and bulk clients.

Let's discuss how our production expertise can bring your footwear project to life.

Contact our team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What are the four main reasons why proper winter footwear is important? Protect Your Health in Cold Weather

- How does ASTM differ from ANSI? Navigating the U.S. Standards System for Compliance

- How are Cordura fabrics categorized, and what does denier (D) measure? Select the Right Fabric for Your Needs

- What are the benefits of custom wheel leather welts and rands in western boots? Discover Superior Craftsmanship & Durability

- What are vapour barrier liners (VBL) and how do they help in winter cycling? | Stay Warm & Dry

- What are the benefits of substituting leather with ecological raw materials? Improve Efficiency & Sustainability

- What are the functions of an industrial-grade 3D depth camera within an automated shoe polishing unit? Expert Analysis

- How do recycled synthetic materials function in sustainable footwear? Build Circular Value Through Innovation