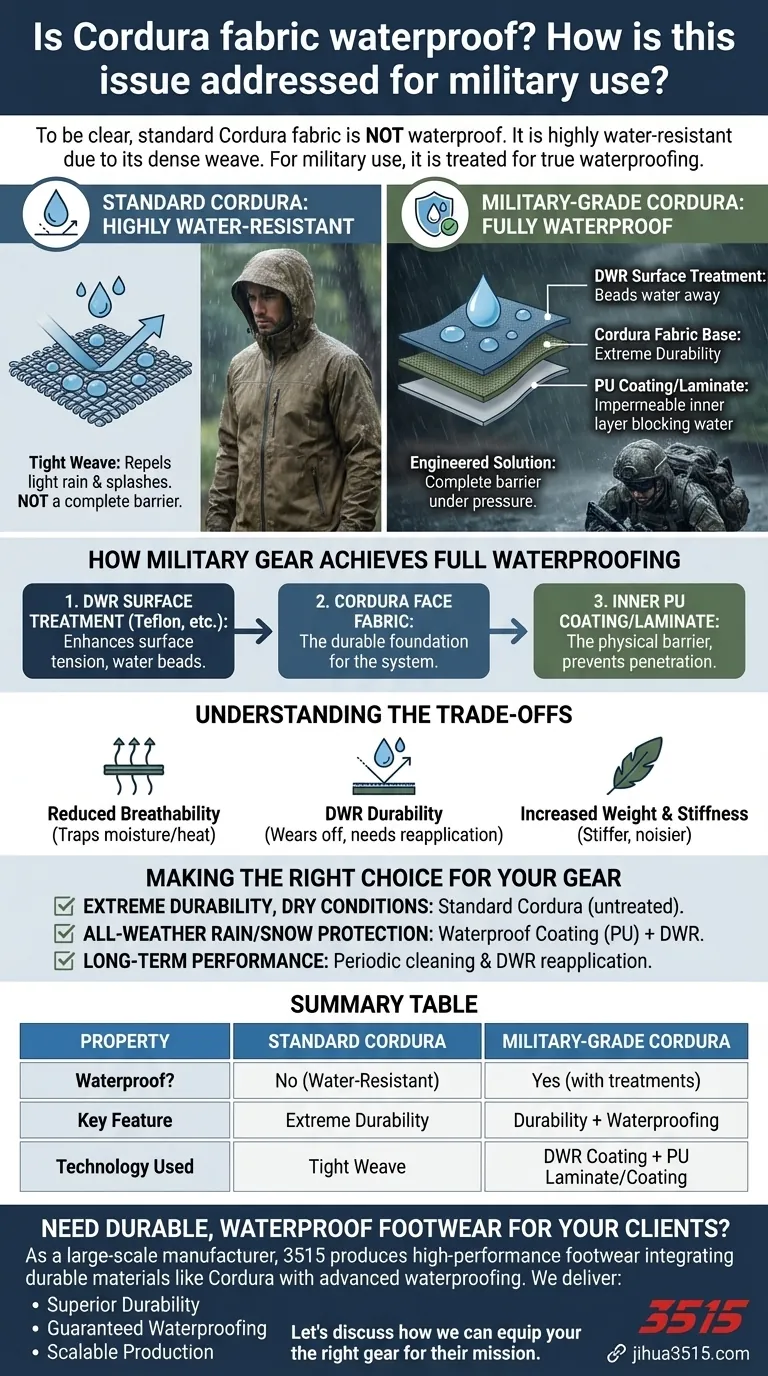

To be clear, standard Cordura fabric is not waterproof. It is, however, highly water-resistant due to its dense weave. For military and other high-performance applications where true waterproofing is non-negotiable, the fabric is treated with additional coatings or laminates to create a complete barrier against moisture.

The core takeaway is that Cordura's legendary reputation is built on its extreme durability and abrasion resistance, not its inherent waterproofness. Its performance in wet conditions is determined entirely by secondary treatments applied by the product manufacturer.

The Foundation: Understanding Cordura's Core Properties

Cordura is not a single fabric but a family of high-performance textiles valued for one primary characteristic: toughness. Understanding this is key to appreciating how it's adapted for different uses.

A Legacy of Durability

The defining feature of Cordura is its exceptional resistance to abrasions, tears, and scuffs. This is why it has become the standard for gear that must endure harsh conditions, from military packs to motorcycle jackets.

The Water-Resistant Weave

The fabric's inherent water resistance comes from its very tight weave. This structure causes water to bead up and roll off the surface, effectively repelling light rain or splashes for a significant period. However, this resistance is not absolute.

Water-Resistant vs. Waterproof: The Critical Distinction

These terms are often used interchangeably, but in technical performance, they mean very different things. The distinction is crucial for understanding military and outdoor gear.

Water-Resistant: The Baseline Performance

A water-resistant fabric can fend off water penetration under light pressure or for a limited time. Standard Cordura fits this description perfectly. It will keep contents dry in a brief shower, but prolonged exposure or heavy downpours will eventually allow water to seep through.

Waterproof: The Engineered Solution

A waterproof fabric provides a complete barrier to water, even when submerged or under sustained pressure. This level of performance is not a natural property of the textile itself but is achieved through additional technology.

How Military Gear Achieves Full Waterproofing

To meet the stringent demands of military use, manufacturers employ a multi-layered approach, turning a water-resistant fabric into a fully waterproof system.

Surface Treatment: DWR Coatings

The first line of defense is a Durable Water Repellent (DWR) treatment applied to the exterior of the fabric. This chemical coating, such as Teflon, enhances surface tension, causing water to bead and roll off before it can even begin to saturate the fibers.

The Inner Barrier: Coatings and Laminates

The real waterproofing happens on the inside. Manufacturers typically apply a polyurethane (PU) coating to the back of the Cordura fabric. This creates an impermeable layer that physically blocks water from passing through, even if the outer fabric becomes saturated.

This combined system—a durable Cordura face fabric, a DWR surface treatment, and a waterproof inner coating—delivers both extreme toughness and reliable protection from the elements.

Understanding the Trade-offs

Achieving waterproof performance in a durable fabric is a balancing act. Every engineering choice comes with compromises that are important to understand.

The Impact on Breathability

Adding a waterproof coating like PU significantly reduces a fabric's breathability. This can trap sweat and moisture vapor inside, which can be a major issue during high-exertion activities. More advanced (and expensive) systems use breathable waterproof membranes to mitigate this.

Durability of Treatments

DWR coatings are not permanent. They wear off over time due to abrasion, dirt, and washing. They must be periodically reapplied to maintain the fabric's ability to shed water from its surface.

Weight and Flexibility

Waterproof coatings and laminates add weight and can make the fabric feel stiffer and noisier. This is a necessary trade-off for achieving robust, all-weather protection.

Making the Right Choice for Your Gear

Your ideal gear depends on understanding how these properties align with your specific needs.

- If your primary focus is extreme durability in mostly dry conditions: A standard, untreated Cordura product offers maximum abrasion resistance and is more than sufficient.

- If your primary focus is all-weather protection from rain and snow: You must seek out gear that explicitly states it has a waterproof coating (like PU) in addition to a DWR treatment.

- If your primary focus is maintaining long-term performance: Be prepared to periodically clean your gear and reapply a DWR spray to preserve its water-shedding capabilities.

Ultimately, understanding that Cordura is the durable foundation for a more complex material system empowers you to select the right gear for your mission.

Summary Table:

| Property | Standard Cordura | Military-Grade Cordura |

|---|---|---|

| Waterproof? | No (Water-Resistant) | Yes (with treatments) |

| Key Feature | Extreme Durability | Durability + Waterproofing |

| Technology Used | Tight Weave | DWR Coating + PU Laminate/Coating |

Need Durable, Waterproof Footwear for Your Clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. We specialize in integrating durable materials like Cordura with advanced waterproofing technologies to create boots and shoes built for the toughest conditions.

We deliver:

- Superior Durability: Footwear that withstands extreme abrasion and wear.

- Guaranteed Waterproofing: Advanced coatings and laminates for complete moisture protection.

- Scalable Production: Reliable supply for all your bulk order needs.

Let's discuss how we can equip your customers with the right gear for their mission.

Contact our expert team today to request a quote

Visual Guide

Related Products

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How should you air out work shoes to keep them fresh? A Guide to Eliminating Odor & Extending Lifespan

- What are the protective advantages of professional safety shoes? Crucial Safety for Fiber Extraction and Finishing

- Why is sole material important in work boots? Unlock the Key to Safety, Comfort & Durability

- Why is choosing the right work boot important? The Ultimate Guide to Industry-Specific Footwear Safety

- How did the brand's fabric technology evolve in the 1970s? From Industrial Toughness to Urban Softness