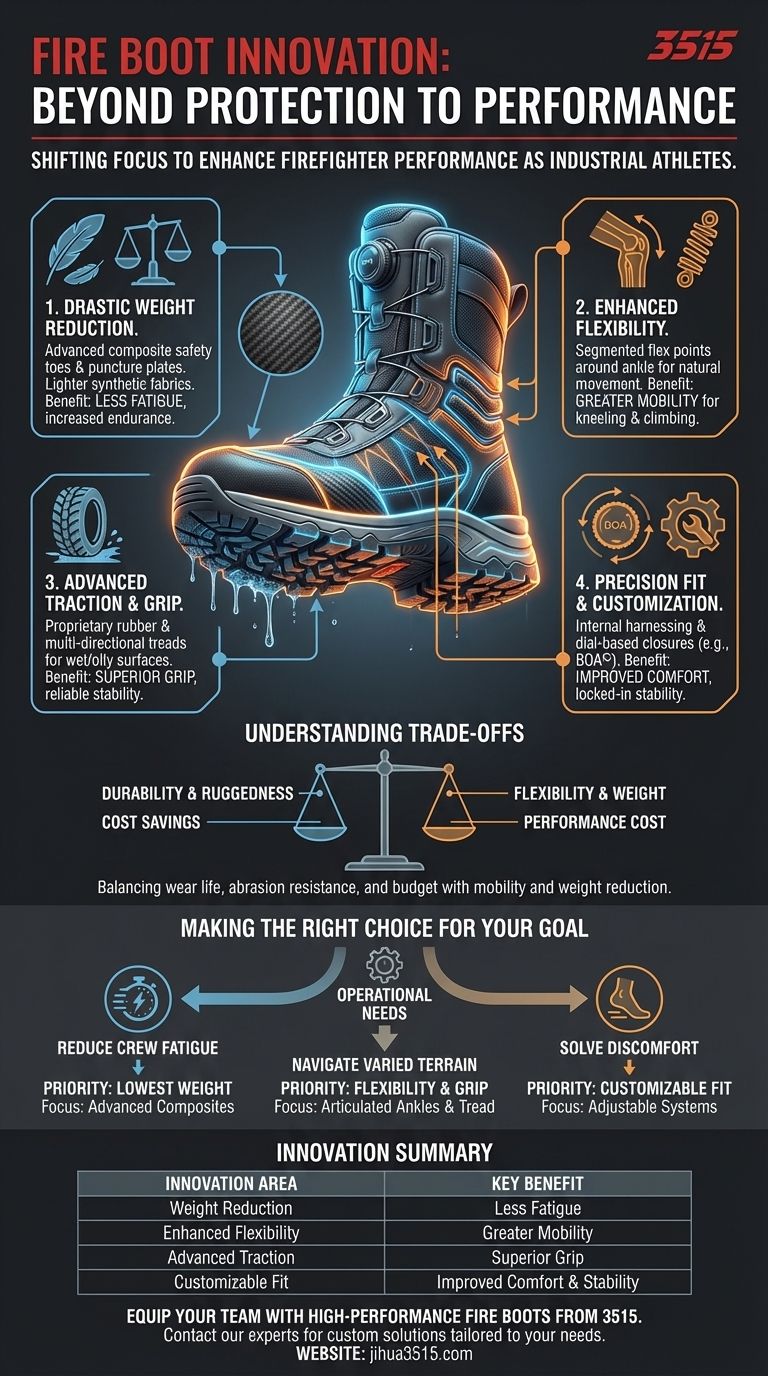

To put it simply, fire boot manufacturers are innovating in four primary areas: reducing weight without sacrificing protection, improving flexibility for greater mobility, enhancing sole grip for unpredictable surfaces, and creating customizable fit systems for superior comfort and stability.

The core goal of modern fire boot innovation is to shift the focus from mere compliance to active performance enhancement. The aim is to reduce firefighter fatigue and increase agility, treating the wearer as an industrial athlete who needs equipment that works with them, not against them.

The Evolution from Protection to Performance

Historically, the primary function of a fire boot was to provide an impenetrable barrier against heat, water, and puncture hazards. While that remains the foundation, the focus has expanded significantly.

Beyond Just Meeting the Standard

Modern boots are designed not just to pass certification tests but to excel in the dynamic, physically demanding reality of firefighting.

This means considering factors like energy return, joint stress, and all-day comfort, which directly impact a firefighter's endurance and effectiveness over a long incident or a full career.

Treating Firefighters as Athletes

The industry now recognizes that firefighting is an athletic endeavor. A lighter, more flexible boot reduces the energy required for each step.

This seemingly small improvement compounds over thousands of steps taken while climbing stairs, carrying equipment, and navigating hazardous terrain, leaving the firefighter with more energy for critical tasks.

Key Areas of Boot Innovation

The most significant advancements are happening in the materials and structural design of the boot, each targeting a specific performance challenge.

1. Drastic Weight Reduction

Manufacturers are using advanced composite materials for safety toes and puncture plates, replacing heavier traditional steel.

Lighter-weight synthetic fabrics and innovative leather treatments also cut ounces from the boot's upper, all while maintaining or exceeding NFPA (National Fire Protection Association) protection standards.

2. Enhanced Flexibility and Mobility

Older boots were often compared to stiff ski boots, restricting natural ankle and foot movement.

New designs incorporate segmented flex points, particularly around the ankle. This allows for easier kneeling, climbing, and pivoting, which is critical when navigating debris or operating on a ladder.

3. Advanced Traction and Grip

Fire scenes present a chaotic mix of surfaces: wet linoleum, icy pavement, oily concrete, and unstable rubble.

Sole technology has advanced with proprietary rubber compounds and aggressive, multi-directional tread patterns. These designs are engineered to shed water and debris while maximizing surface contact for reliable grip.

4. Precision Fit and Customization

A poorly fitting boot can cause blisters, hot spots, and dangerous instability.

Innovations include internal harnessing systems and dial-based closures (like the BOA® Fit System) that allow firefighters to micro-adjust the fit. This locks the heel in place and eliminates internal foot slippage, improving both comfort and control.

Understanding the Trade-offs

While innovative, new designs introduce variables that must be carefully considered. No single boot is perfect for every application, and every design choice involves a compromise.

Durability vs. Flexibility

Highly flexible materials may, in some cases, have a shorter wear life than traditional, rigid leather. Departments must balance the need for mobility with their boot replacement cycles and budget.

Weight vs. Ruggedness

The lightest boots on the market may achieve their weight reduction by using materials that are less resistant to the extreme physical abrasion common in training exercises or structural collapse scenarios.

Cost of Innovation

Advanced materials and complex designs invariably come at a higher price point. The performance benefits must be weighed against departmental budget constraints.

Making the Right Choice for Your Goal

When evaluating new boots, understanding your department's specific operational needs is the most critical step.

- If your primary focus is reducing crew fatigue during long incidents: Prioritize boots with the lowest overall weight that still meet your structural firefighting requirements.

- If your crews frequently navigate confined spaces or varied terrain: Focus on models that emphasize flexibility through articulated ankle designs and enhanced sole grip.

- If you are trying to solve issues with foot injuries or poor morale due to discomfort: Invest in boots that feature advanced, customizable fit systems to accommodate different foot shapes.

Ultimately, the right boot is a critical piece of equipment that directly enhances a firefighter's safety, endurance, and operational effectiveness.

Summary Table:

| Innovation Area | Key Benefit |

|---|---|

| Weight Reduction | Less fatigue with advanced composite materials |

| Enhanced Flexibility | Greater mobility with segmented ankle designs |

| Advanced Traction | Superior grip on wet, oily, and unstable surfaces |

| Customizable Fit | Improved comfort and stability with internal harness systems |

Equip Your Team with High-Performance Fire Boots from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of advanced footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including the latest innovations in firefighting footwear designed to enhance performance, reduce fatigue, and maximize safety.

Ready to upgrade your fleet's gear? Contact our experts today to discuss custom solutions tailored to your department's specific operational needs and budget.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What factors should be considered when choosing work boots? Prioritize Safety, Fit, and Durability

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- How do cowboy boots benefit construction workers? Enhance Safety and Support on the Job Site

- What are some alternatives to motorcycle boots? Balancing Safety, Comfort, and Budget

- Why is a proper fit important for work-safe boots? The Foundation of Safety, Comfort & Performance

- What work boot features are essential for warehouse and light industrial settings? Prioritize Lightweight Protection & All-Day Comfort

- What are the different types of boot toes available? Choose the Right Toe for Your Job

- What are the key parts of a work boot's interior? The 3 Core Components for All-Day Comfort & Support