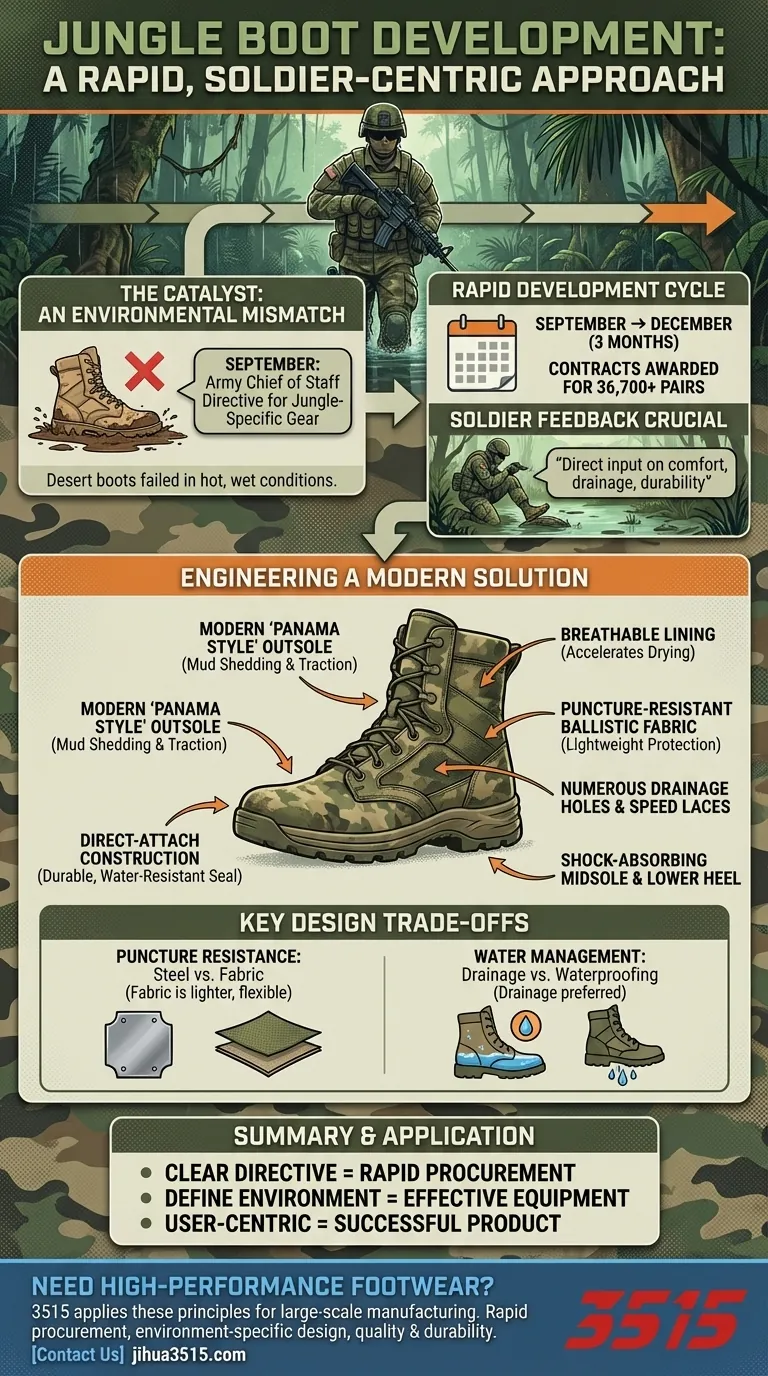

The development of the new Army Jungle Combat Boot (JCB) was initiated by a direct order from the Army Chief of Staff in September. This directive specifically aimed to equip two brigade combat teams in Hawaii with footwear suitable for their operational environment, with contracts being awarded just three months later in December.

The new jungle boot was not merely an upgrade, but a direct response to an identified capability gap. Standard-issue combat boots, optimized for desert climates, were failing soldiers in hot, wet environments, prompting a rapid development cycle that blended proven historical designs with modern materials and soldier feedback.

The Catalyst for Change: An Environmental Mismatch

The need for a new jungle boot arose from a fundamental problem: the equipment was not suited for the environment. The U.S. Army's focus on conflicts in Iraq and Afghanistan had led to the perfection of boots for dry, sandy conditions.

The Failure of Standard-Issue Boots

The standard-issue combat boot performed exceptionally well in desert theaters. However, when used in hot and wet jungle conditions, its design proved to be a significant liability, failing to drain water or dry out effectively.

A Directive from Leadership

Recognizing this critical shortcoming, the Army Chief of Staff issued a clear directive in September. The goal was to develop and procure a purpose-built jungle boot for specific units operating in the Pacific, starting with two brigade combat teams in Hawaii.

From Concept to Contract: A Rapid Development Cycle

The process moved with remarkable speed, demonstrating the urgency of the need. The timeline from the initial directive to awarding production contracts was condensed into a single quarter.

The Three-Month Timeline

By December, just three months after the initial order, the Army awarded contracts to two U.S. manufacturers. This initial order was for over 36,700 pairs, signaling a serious commitment to resolving the issue quickly.

The Central Role of Soldier Feedback

The design was not finalized in a lab. Early versions of the boot were sent to soldiers for testing in actual jungle environments. Their direct feedback on comfort, drainage, and durability was crucial in refining the final product.

Engineering a Modern Solution

The JCB's design is a thoughtful combination of historical lessons and modern technological advancements. It acknowledges what worked in the past while leveraging new materials to overcome old limitations.

Learning from the Past: The M1966 Boot

The new boot draws heavy inspiration from the successful Vietnam-era M1966 jungle boot. Most notably, it features a modern version of the classic 'Panama style' outsole, known for its ability to shed mud and maintain traction.

Integrating Modern Materials and Construction

While the sole's concept is classic, the rest of the boot is thoroughly modern. It uses a direct-attach construction, where liquid foam is used to bond the sole to the upper, creating a durable and water-resistant seal.

Prioritizing Performance Features

Key upgrades include a shock-absorbing midsole for comfort, a lower heel height to prevent snagging on roots, and numerous drainage holes. The boot also features speed laces, a redesigned upper for a better fit, and a breathable lining to accelerate drying.

Understanding the Key Design Trade-offs

Creating the JCB involved making deliberate choices to optimize for the jungle environment, often trading one feature for another.

Puncture Resistance: Steel vs. Fabric

Instead of the heavy steel plates used in older boots for puncture protection, the JCB uses a puncture-resistant ballistic fabric layer. This provides necessary protection while significantly reducing weight and increasing flexibility.

Durability: Direct-Attach Construction

The choice of a direct-attach sole is a critical durability feature. This modern construction method is superior to older methods in wet conditions, where glues and stitching can fail over time due to constant moisture exposure.

Water Management: Drainage Over Waterproofing

Perhaps the most important principle is the focus on drainage over waterproofing. The design accepts that feet will get wet in a jungle. The goal is not to keep water out, but to let it escape as quickly as possible so the boot and foot can dry.

Applying These Lessons to Your Project

The JCB's development offers a clear model for successful, purpose-driven equipment design.

- If your primary focus is rapid procurement: A clear, high-level directive can cut through bureaucracy and empower teams to move from concept to contract in months.

- If your primary focus is equipment effectiveness: Ruthlessly define the operational environment and design specifically for its challenges, rather than seeking a single solution for all scenarios.

- If your primary focus is user-centric design: There is no substitute for putting prototypes in the hands of end-users and iteratively refining the product based on their real-world feedback.

Ultimately, this process serves as a powerful example of how to solve a critical problem by correctly identifying the need and executing a focused, feedback-driven plan.

Summary Table:

| Key Development Phase | Timeline & Action |

|---|---|

| Catalyst | September: Army Chief of Staff directive identifies equipment gap for jungle warfare. |

| Procurement | December: Contracts awarded to manufacturers for over 36,700 pairs. |

| Core Design Principle | Focus on drainage over waterproofing; modern materials meet historical design. |

| Key to Success | Continuous integration of direct soldier feedback during testing. |

Need High-Performance Footwear for Your Market?

The development of the Army Jungle Combat Boot demonstrates the power of a focused, rapid, and user-centric approach to manufacturing. As a large-scale manufacturer, 3515 applies these same principles to produce a comprehensive range of footwear for distributors, brand owners, and bulk clients.

We can help you:

- Rapidly Procure custom or standard footwear solutions.

- Design for Specific Environments with modern materials and construction.

- Ensure Quality & Durability through rigorous testing and direct-attach construction.

Let's discuss how our production capabilities can meet your specific needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

People Also Ask

- Why are slip-resistant military boots important? The Foundation of Soldier Safety and Mission Success

- What are the steps to clean suede military boots? A Complete Guide to Gentle, Effective Care

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon

- What is the proper method to clean military boots? A Step-by-Step Guide to Maximize Longevity