To properly dry and maintain your work shoe insoles, you must remove them from your shoes each day and let them air dry at room temperature. The most critical step is to avoid using any direct heat sources, such as a hairdryer, radiator, or clothes dryer, as this can permanently damage their supportive shape and materials.

The key to extending the life and comfort of your insoles isn't a single cleaning trick, but a consistent daily routine focused on air circulation and avoiding the material-degrading effects of direct heat.

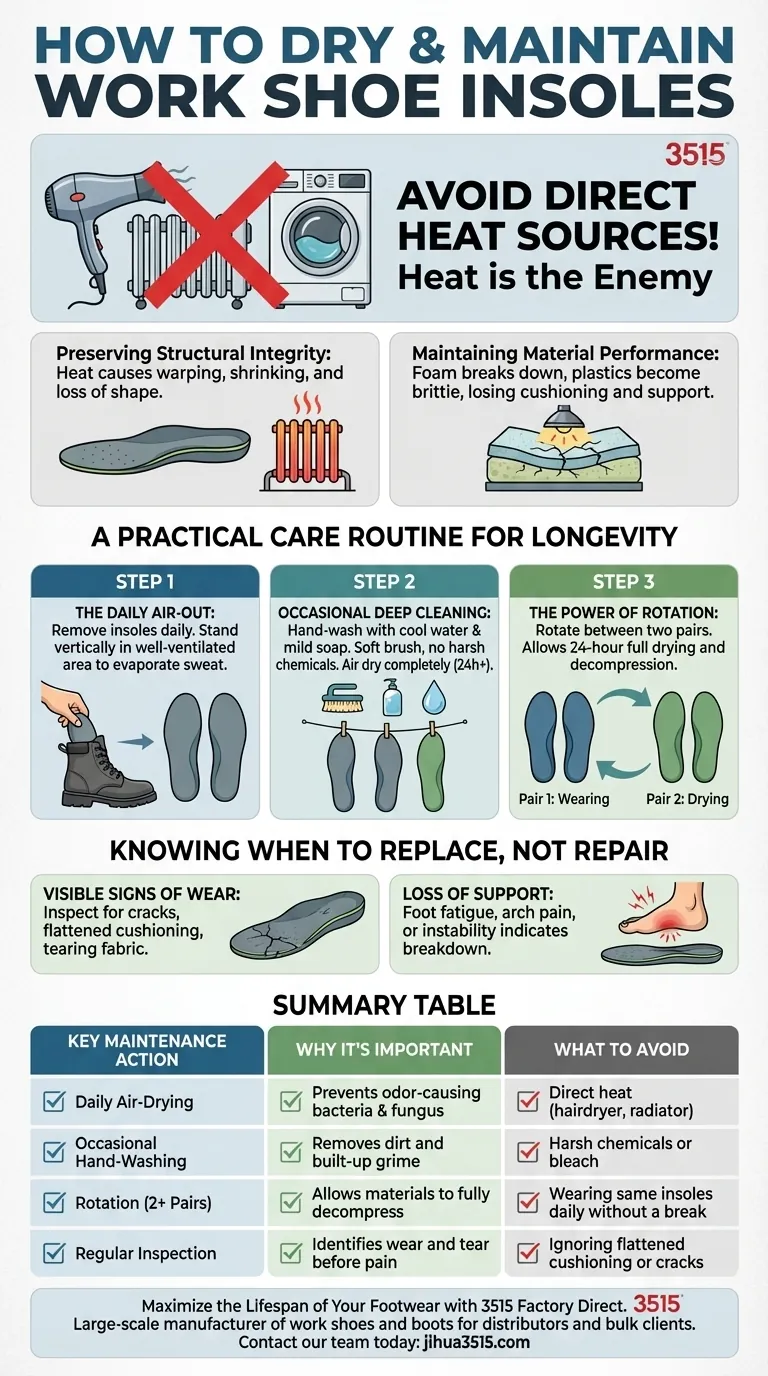

The Foundational Principle: Why Heat is the Enemy

Understanding why you must avoid heat is crucial for proper insole care. Insoles, especially supportive or orthopedic models, are engineered with specific materials that are sensitive to temperature changes.

Preserving Structural Integrity

Most performance insoles are made from molded foams, gels, and plastics. Applying direct heat can cause these materials to warp, shrink, or lose their carefully designed anatomical shape. This fundamentally compromises their ability to support your arch and cushion impact.

Maintaining Material Performance

Heat doesn't just change the shape; it degrades the material itself. The foam cells that provide cushioning can break down and compress permanently, and the supportive plastics can become brittle. This results in a loss of both comfort and functional support.

A Practical Care Routine for Longevity

Effective maintenance is about creating simple, repeatable habits. A combination of daily drying and periodic cleaning will prevent odor and preserve the insole's function for as long as possible.

The Daily Air-Out

At the end of every workday, remove your insoles from your shoes. Stand them up vertically in a well-ventilated area. This simple act allows moisture from sweat to evaporate completely, which is the single most effective way to prevent the growth of odor-causing bacteria and fungus.

Occasional Deep Cleaning

For built-up dirt and odor, hand-wash your insoles. Use a soft brush with cool water and a mild soap or detergent. Avoid harsh chemicals or bleach. After washing, gently squeeze out excess water and let them air dry completely before re-inserting them—this may take 24 hours or more.

The Power of Rotation

If you wear the same work boots daily, especially in demanding conditions, consider investing in a second pair of identical insoles. By rotating them each day, you guarantee that one pair has a full 24 hours to dry and decompress, dramatically extending the life and hygiene of both.

Knowing When to Replace, Not Repair

Even with perfect care, insoles are consumable items that wear out. Recognizing the signs of failure is key to preventing foot pain and injury.

Visible Signs of Wear

Inspect your insoles regularly for cracks in the foam, flattened cushioning (especially in the heel and ball of the foot), or any tearing of the top fabric. These are clear indicators that the materials have reached the end of their functional life.

Loss of Support

The most important sign is how your feet feel. If you begin to experience the return of foot fatigue, arch pain, or instability that the insoles previously solved, their supportive structure has likely broken down, and it is time for a new pair.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your primary concern.

- If your primary focus is odor control: The non-negotiable step is removing the insoles for daily air-drying.

- If your primary focus is preserving maximum support: Rotating between two pairs is the most effective way to allow the materials to fully decompress and last longer.

- If your primary focus is dealing with extreme moisture: After air-drying, consider placing them near a fan (using cool air) to accelerate evaporation without the damage of heat.

Proper care transforms your insoles from a simple accessory into a lasting component of your daily comfort and support system.

Summary Table:

| Key Maintenance Action | Why It's Important | What to Avoid |

|---|---|---|

| Daily Air-Drying | Prevents odor-causing bacteria and fungus. | Direct heat (hairdryer, radiator). |

| Occasional Hand-Washing | Removes dirt and built-up grime. | Harsh chemicals or bleach. |

| Rotation (2+ Pairs) | Allows materials to fully decompress. | Wearing the same insoles daily without a break. |

| Regular Inspection | Identifies wear and tear before it causes pain. | Ignoring flattened cushioning or cracks. |

Maximize the Lifespan of Your Footwear with 3515 Factory Direct

Just as proper care extends the life of your insoles, starting with high-quality footwear is the foundation of long-term comfort and durability. As a large-scale manufacturer, 3515 produces a comprehensive range of work shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and occupational footwear built with quality materials from the ground up.

Let us help you provide superior products that stand up to the toughest conditions. Contact our team today to discuss your manufacturing needs and receive a competitive quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries