The short answer is a consistent routine of cleaning, conditioning, proper drying, and regular inspection. Unlike steel toes, composite materials don't rust, but the surrounding materials—especially leather—require dedicated care to prevent cracking, deterioration, and loss of structural integrity, which is critical for both safety and comfort.

Your composite toe boots are a system where every part supports the others. Caring for the leather, sole, and seams is just as important as protecting the toe cap itself, as the failure of one component compromises the entire boot.

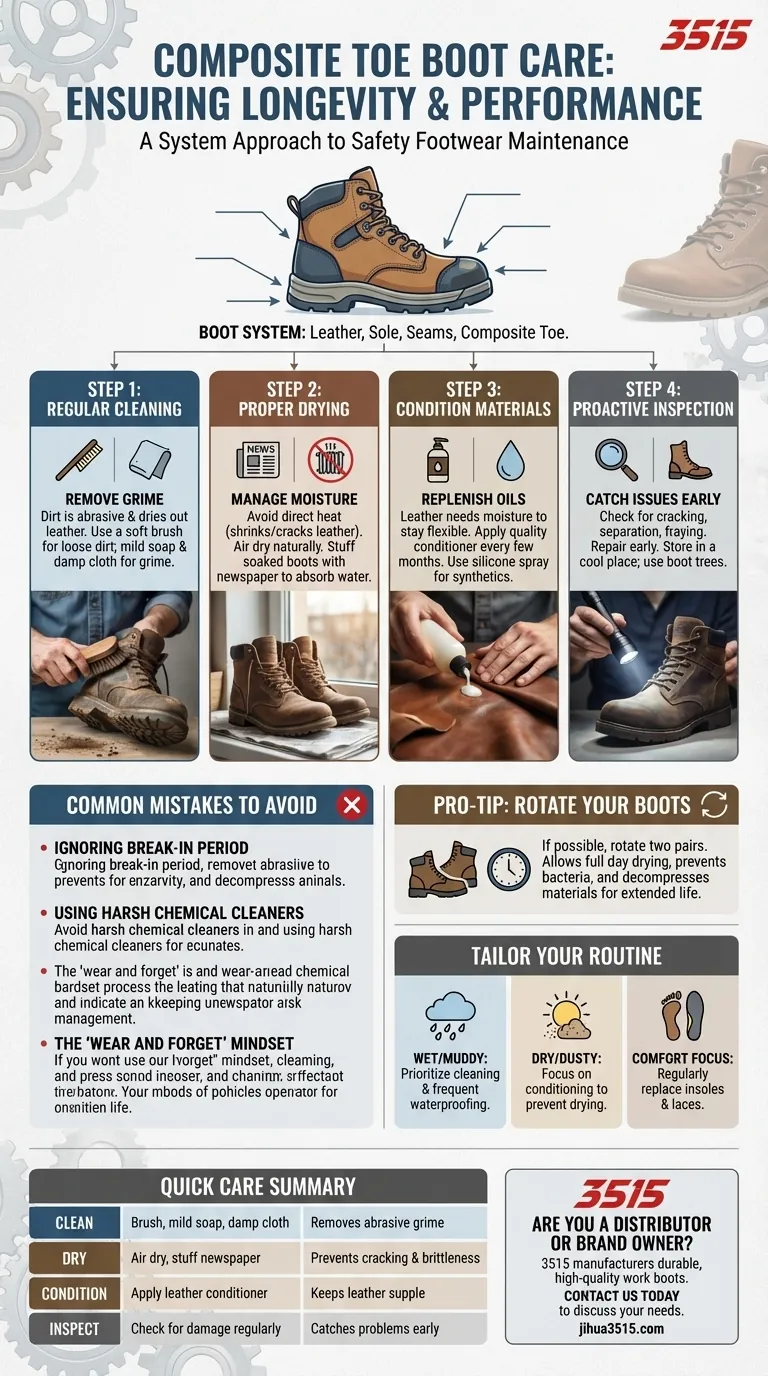

The Core Principles of Boot Longevity

Caring for high-quality work boots isn't about a single action but a consistent habit. The goal is to manage moisture, maintain material flexibility, and prevent the gradual breakdown caused by dirt, chemicals, and physical stress.

Step 1: Regular Cleaning

Dirt and grime are more than cosmetic issues; they actively degrade your boots.

Dirt particles are abrasive and can wear down stitching and leather fibers over time. More critically, embedded dirt draws essential oils out of the leather, leading to dryness and cracking.

For routine cleaning, use a soft brush to remove loose dirt and a damp cloth with mild soap for more stubborn grime.

Step 2: Proper Drying Technique

Moisture is the enemy of most boot materials, especially leather. How you dry your boots is one of the most critical factors in their lifespan.

Never use direct heat sources like a radiator, campfire, or hair dryer. This "cooks" the leather, causing it to shrink, become brittle, and crack irreparably.

The best method is to let them air dry naturally in a cool, well-ventilated area. If they are soaked, stuff them with newspaper to absorb excess moisture and help them retain their shape.

Step 3: Conditioning the Materials

Conditioning is the process of replenishing the oils that keep leather flexible and water-resistant. This is non-negotiable for leather boots.

Think of leather like your own skin; without moisture, it dries out and cracks. A quality leather conditioner, applied every few months (or monthly in harsh conditions), keeps the material supple.

For boots made of synthetic materials or rubber, a silicone-based waterproofing spray can help protect the material and seams from moisture damage.

Step 4: Proactive Inspection and Storage

Small problems become big problems when ignored. Regular inspection allows you to catch issues early.

Periodically check for cracking leather, separating soles, and frayed seams. Addressing these issues with a cobbler or appropriate repair kit can significantly extend the boot's life.

When not in use, store your boots in a cool, dry place away from direct sunlight. Using boot trees or stuffing the shaft helps maintain their shape and prevent creasing.

Understanding the Trade-offs and Common Mistakes

Proper care requires a small investment of time, but neglecting it leads to premature failure and unnecessary costs.

Mistake 1: Ignoring the Break-in Period

New boots, especially leather ones, need time to conform to your feet. Wearing them for short periods initially prevents the excessive stress that can damage seams before the material has a chance to adapt.

Mistake 2: Using the Wrong Cleaning Products

Harsh chemical cleaners or detergents can strip the natural oils from leather, causing severe damage. Always stick to mild saddle soap or products specifically designed for boot care.

Mistake 3: The "Wear and Forget" Mindset

Work boots endure extreme conditions. Assuming they don't need regular maintenance is the fastest way to ruin them. A five-minute wipe-down after a dirty job can add months to their lifespan.

Pro-Tip: Rotate Your Boots

If possible, having two pairs of work boots to rotate between is the single best thing you can do for longevity. This gives each pair a full day to dry out completely, which prevents the growth of bacteria and allows the materials to rest and decompress.

Making the Right Choice for Your Goal

Your maintenance routine should adapt to your work environment.

- If your primary focus is working in wet or muddy conditions: Prioritize regular cleaning to remove corrosive mud and apply a waterproofing treatment more frequently.

- If your primary focus is working in dry, dusty environments: Pay close attention to conditioning, as dust and dirt will pull moisture from the leather very quickly.

- If your primary focus is maximizing comfort and support: Regularly inspect and replace worn-out insoles and laces to maintain the boot's internal structure.

Ultimately, treating your work boots as a critical piece of equipment, not just footwear, is the key to ensuring they protect you for years to come.

Summary Table:

| Step | Key Action | Why It's Important |

|---|---|---|

| 1. Clean | Brush off dirt; use mild soap & damp cloth | Removes abrasive grime that degrades leather and stitching |

| 2. Dry | Air dry naturally; stuff with newspaper if wet | Prevents leather from becoming brittle and cracking |

| 3. Condition | Apply leather conditioner every few months | Keeps leather supple and water-resistant |

| 4. Inspect | Check for cracks, separating soles, frayed seams | Catches small problems before they become major failures |

Are you a distributor, brand owner, or bulk buyer in need of durable, high-quality work boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear designed for demanding work environments. Our production capabilities encompass all types of safety boots, including composite toe models crafted with longevity in mind.

Contact us today to discuss your specific needs and discover how our manufacturing expertise can provide reliable, long-lasting footwear for your customers or workforce.

Visual Guide

Related Products

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- When should you seek immediate medical care while wearing a walking boot? Recognize Critical Warning Signs

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort