The definitive way to select safety footwear is by conducting a thorough hazard assessment of the specific work environment. You must first identify every potential risk—from falling objects and sharp ground hazards to electrical currents and slippery surfaces—and then match those specific risks to footwear certified to protect against them.

The goal is not simply to buy a "safety shoe," but to implement a protective system. This requires a methodical process of identifying worksite risks, decoding protection standards, and selecting footwear with the precise features certified to mitigate those specific dangers.

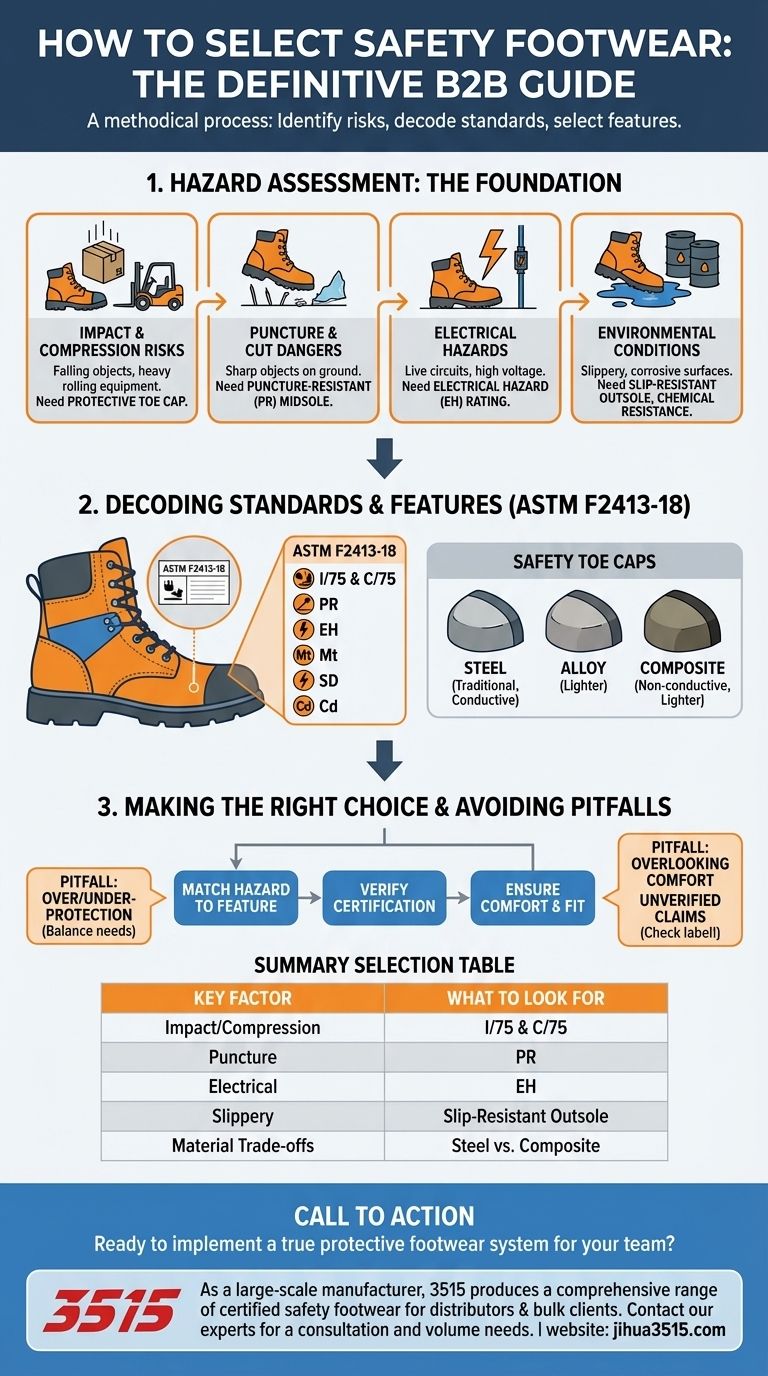

The Foundation: A Comprehensive Hazard Assessment

Before you can select the right boot, you must deeply understand the environment where it will be used. Every workplace is unique, and a generic approach to safety footwear is a direct risk to employee well-being.

Identifying Impact and Compression Risks

The most common workplace foot injuries come from falling objects or compression from heavy rolling equipment.

A hazard assessment must identify any work involving lifting heavy materials, working near forklifts, or operating any machinery where an object could fall or roll onto a worker's foot. Footwear must have a certified protective toe cap.

Assessing Puncture and Cut Dangers

Construction sites, demolition zones, and recycling facilities often have sharp objects like nails, screws, metal shards, or broken glass on the ground.

If workers walk on surfaces where such dangers are present, the footwear selected must include a puncture-resistant (PR) plate in the midsole to protect the sole of the foot.

Evaluating Electrical Hazards

Working near live circuits or with high-voltage equipment presents a risk of electric shock.

In these situations, it is critical to select footwear with an Electrical Hazard (EH) rating. These shoes are manufactured with non-conductive, shock-resistant soles and heels to provide a secondary source of protection.

Analyzing Environmental Conditions

The ground surface itself is a primary source of risk. An assessment must account for water, oil, chemicals, and uneven terrain.

For wet or oily environments, a slip-resistant outsole is non-negotiable. If corrosive substances are present, the boot's upper material must be able to resist chemical burns and degradation.

Decoding Safety Footwear Features and Standards

Once you have identified the hazards, you can translate them into the specific features and certifications required for your footwear. The label inside the shoe's tongue provides this critical information.

The Mandate for Certified Protection

In the United States, OSHA (29 CFR 1910.136) mandates that protective footwear comply with standards set by ASTM International.

The current governing standard is ASTM F2413-18. Any footwear you consider legitimate safety footwear must meet this standard, which requires a built-in protective toe cap at minimum.

Understanding the Safety Toe Cap

The safety toe is the footwear's first line of defense against impact and compression.

They are typically made of steel, aluminum alloy, or composite materials (like carbon fiber or plastic). All are tested to the same I/75 and C/75 standards, indicating protection against 75 foot-pounds of impact and 2,500 pounds of compression.

Key Protective Classifications on the Label

The ASTM F2413 label uses simple codes to identify the specific hazards the shoe protects against. Look for these markings:

- I/75: Impact resistance (75 foot-pounds)

- C/75: Compression resistance (2,500 pounds)

- Mt: Metatarsal protection for the top of the foot

- PR: Puncture Resistance

- EH: Electrical Hazard protection

- SD: Static Dissipating

- Cd: Conductive protection

Common Pitfalls and Selection Trade-offs

Choosing the right shoe involves more than matching a hazard to a feature code. Avoiding common mistakes is essential for a successful safety program.

Overlooking Comfort and Fit

A certified boot that is too uncomfortable to wear correctly is useless. Poor fit can cause blisters, fatigue, and distraction, leading to other accidents.

Proper fit is a safety feature, not a luxury. Ensure employees are properly sized and that the footwear provides adequate arch and ankle support for long shifts.

Failing to Verify Certification

Never take safety claims at face value. Always purchase from reputable suppliers and check the shoe's internal label for the ASTM F2413 marking.

If in doubt, request a technical data sheet from the manufacturer to confirm its certifications and protective qualities.

The Risk of Over- or Under-Protection

Selecting a boot with unnecessary features adds weight, reduces flexibility, and increases cost. Conversely, failing to select a boot with a necessary feature, like PR or EH, creates a direct and unacceptable safety failure.

Your hazard assessment should guide you to a balanced choice—everything you need and nothing you don't.

Choosing the Right Toe Material

While steel, alloy, and composite toes are all tested to the same standard, they have distinct trade-offs.

Steel is the traditional choice, but it conducts temperature. Composite toes are lighter, do not conduct heat or cold, and are ideal for metal-free work environments, but they can be slightly bulkier.

Making the Right Choice for Your Environment

Use your hazard assessment to guide your final decision. Your selection should be a direct response to the risks your team faces every day.

- If your primary risk is falling objects or heavy machinery: Prioritize footwear with the highest impact (I/75) and compression (C/75) ratings, and consider metatarsal guards (Mt).

- If your workers face sharp underfoot hazards: Ensure the footwear is explicitly rated for Puncture Resistance (PR).

- If you work near live electrical circuits: Select footwear with an Electrical Hazard (EH) rating to provide a secondary source of protection.

- If your environment involves wet or oily surfaces: The single most critical feature is a highly slip-resistant outsole designed for those specific conditions.

- If workers operate in high-security areas or extreme temperatures: Choose non-metallic footwear with lighter, non-conductive composite safety toes.

A methodical approach transforms footwear selection from a simple purchase into a critical component of your safety program.

Summary Table:

| Key Selection Factor | What to Look For |

|---|---|

| Impact/Compression | ASTM F2413 rating: I/75 & C/75 (Safety Toe) |

| Puncture Hazards | ASTM F2413 rating: PR (Puncture Resistant Midsole) |

| Electrical Hazards | ASTM F2413 rating: EH (Electrical Hazard Protection) |

| Slippery Surfaces | Slip-Resistant Outsoles |

| Material Trade-offs | Steel (traditional), Composite (lightweight, non-conductive) |

Ready to implement a true protective footwear system for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the precise ASTM F2413 standards your hazard assessment demands.

Let us help you match the right protective features to your specific workplace risks. Contact our experts today for a consultation and to discuss your volume needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- Why do my feet hurt when I wear safety shoes? Solve Toe Pain, Blisters & Fatigue

- What is the primary function of a cooling system in safety shoe production? Ensure Structural Integrity and Speed

- What are the key features of NFPA-certified fire boots? Essential Protection for Firefighters

- How does a dual-belt medical treadmill contribute to the gait analysis of safety footwear? Precision Kinetic Testing

- How do pressure-sensing insoles achieve load sensing? Optimize Industrial Safety with Real-Time Physical Load Data

- What standards regulate safety footwear? Understand ASTM vs. EN ISO for Compliance

- What is the primary function of specialized protective footwear within the configuration of Level 3 PPE? Expert Insights

- What specific protective features do professional safety shoes provide for stroke survivors? Enhance Workplace Safety