To clean safety boots without causing damage, you must use a gentle approach. The correct method involves using lukewarm water mixed with a mild soap, scrubbing with a soft-bristled brush to remove dirt, and then allowing the boots to air dry slowly, completely away from any direct heat sources.

The goal of cleaning is not just cosmetic; it is essential maintenance. Proper cleaning preserves the integrity of the boot's materials, ensuring they continue to provide the protection and durability you rely on.

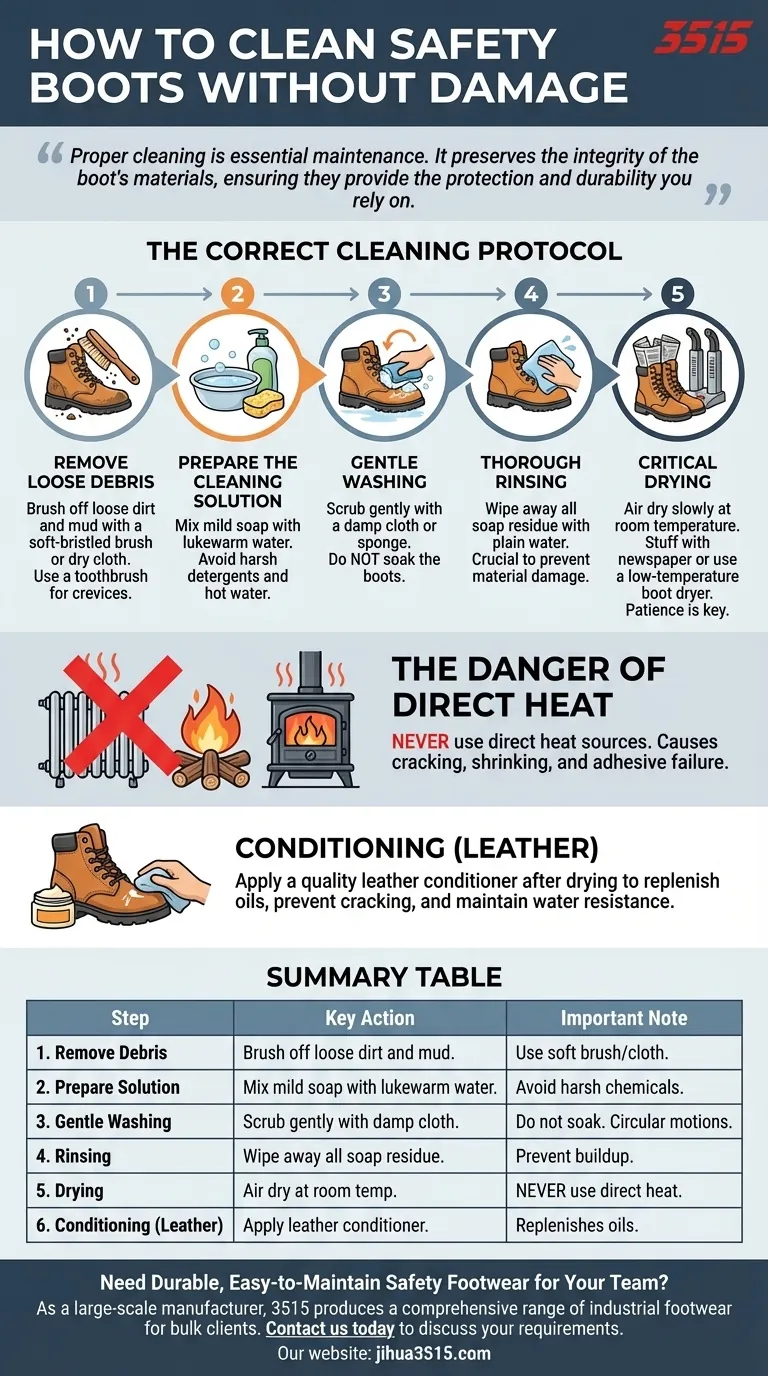

The Correct Cleaning Protocol

Effective cleaning is a multi-step process. Each stage is designed to remove contaminants while protecting the boot's structural materials, whether they are leather, rubber, or synthetic fabrics.

Step 1: Remove Loose Debris

Before introducing water, you must remove all loose dirt and mud. Use a soft-bristled brush or a dry cloth to knock off any caked-on material.

A toothbrush can be useful for getting into the crevices of the sole and around the welt.

Step 2: Prepare the Cleaning Solution

The right cleaning solution is critical. Harsh detergents can strip natural oils from leather and degrade synthetic materials.

Mix a small amount of mild soap (like dish soap) or a specialized boot cleaner into a bucket of lukewarm water. Avoid hot water, as it can damage leather and adhesives.

Step 3: Gentle Washing

Dip a soft cloth, sponge, or soft brush into the soapy water. Wring it out so it is damp, not soaking wet.

Gently scrub the entire surface of the boot in a circular motion. Focus on any stained areas, but do not apply excessive pressure that could scratch the material.

Step 4: Thorough Rinsing

After scrubbing, use a separate clean cloth dampened with plain water to wipe away all soap residue.

It is crucial to remove all soap, as leftover film can attract more dirt and dry out the boot's materials. Do not submerge or soak the boots to rinse them.

The Critical Drying Phase

How you dry your boots is just as important as how you wash them. Improper drying is the fastest way to permanently damage leather and compromise the boot's construction.

The Danger of Direct Heat

Never place wet boots near a direct heat source like a campfire, radiator, or woodstove.

Intense heat causes leather to dry too quickly, leading to cracking, shrinking, and brittleness. It can also weaken the adhesives used to bond the sole, causing it to delaminate.

The Safe Way to Dry

Patience is key. Boots must be allowed to dry slowly and naturally at room temperature.

Stuff them with newspaper to absorb internal moisture, changing the paper when it becomes saturated. Alternatively, use a commercial boot dryer that uses low-temperature, circulating air.

Common Mistakes That Damage Boots

Avoiding common pitfalls is essential for extending the life of your footwear. Many well-intentioned cleaning efforts do more harm than good.

Using Harsh Chemicals

Aggressive cleaners, solvents, or detergents will damage your boots. They strip protective coatings, discolor materials, and can corrode the boot's structure over time. Stick to mild soap.

Forgetting to Condition

After a thorough cleaning and drying, leather boots need conditioning. A quality leather conditioner replenishes the natural oils that were washed away.

This step keeps the leather supple, prevents cracking, and maintains its water-resistant properties.

A Simple Routine for Maximum Longevity

Tailor your cleaning frequency to your usage to ensure your boots are always ready and protected.

- If you work in consistently muddy or wet conditions: Perform a quick wipe-down with a damp cloth daily and a full, deep clean weekly.

- If you use your boots for occasional projects: Clean them thoroughly after each use before putting them into storage.

- If your primary focus is preserving leather: Always apply a leather conditioner or protective spray after the boots have completely dried from a deep clean.

Consistent, gentle care is the single best investment you can make in the longevity and safety of your boots.

Summary Table:

| Step | Key Action | Important Note |

|---|---|---|

| 1. Remove Debris | Brush off loose dirt and mud. | Use a soft-bristled brush or dry cloth. |

| 2. Prepare Solution | Mix mild soap with lukewarm water. | Avoid harsh detergents and hot water. |

| 3. Gentle Washing | Scrub gently with a damp cloth/brush. | Do not soak the boots; use circular motions. |

| 4. Rinsing | Wipe away all soap residue with clean water. | Crucial to prevent dirt buildup and material damage. |

| 5. Drying | Air dry at room temperature; stuff with newspaper. | Never use direct heat sources like radiators. |

| 6. Conditioning (Leather) | Apply a quality leather conditioner after drying. | Replenishes oils to prevent cracking and maintain water resistance. |

Need Durable, Easy-to-Maintain Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered for durability and simplified maintenance to reduce long-term costs.

Contact us today to discuss your specific requirements and discover how our reliable footwear solutions can enhance your safety standards and operational efficiency.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene