An employee's role in the effectiveness of safety footwear extends far beyond simply wearing it. True contribution involves a cycle of consistent use, diligent maintenance, prompt reporting of any defects, and active participation in safety training. These four actions transform personal protective equipment from a passive requirement into an active layer of defense.

The ultimate effectiveness of a safety shoe program does not rest on the equipment itself, but on the employee's transition from passive compliance to active ownership of their own safety.

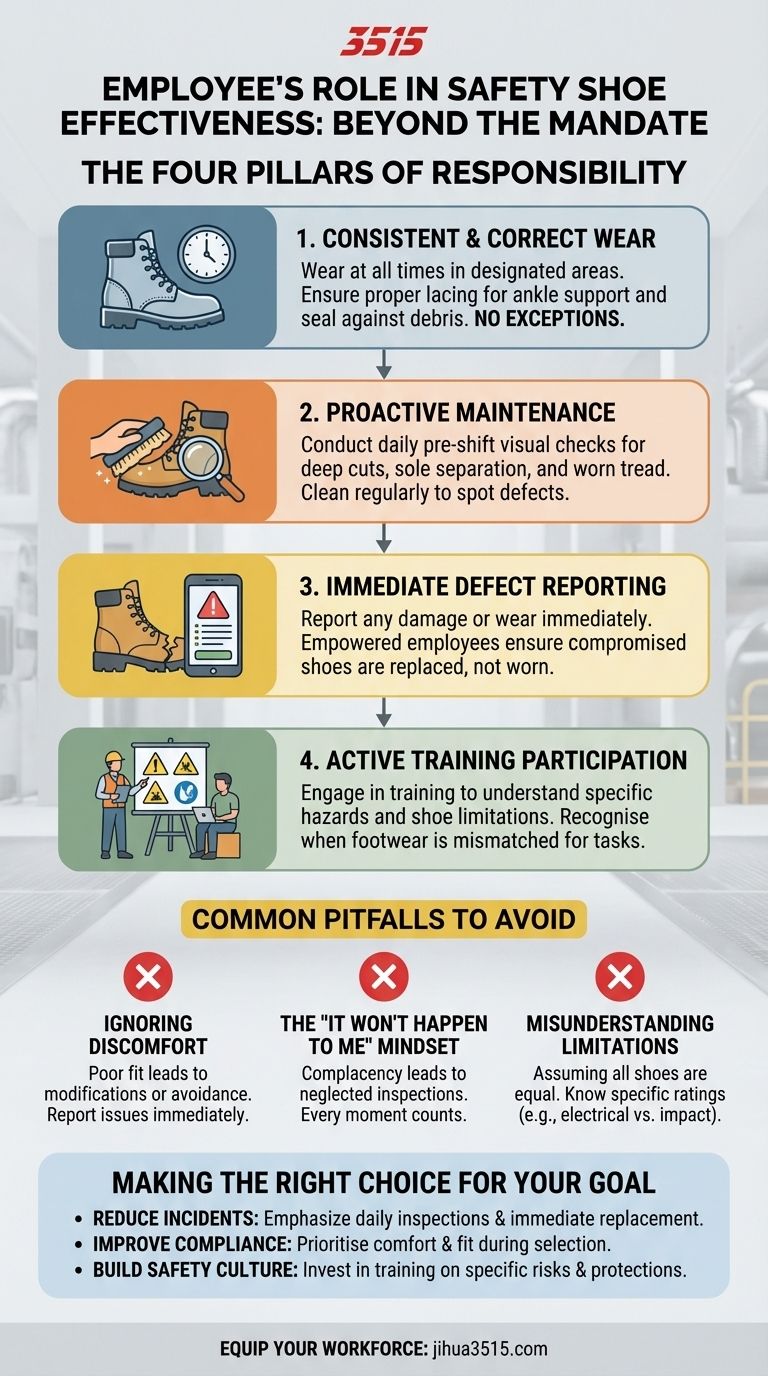

Beyond the Mandate: The Four Pillars of Employee Responsibility

For safety footwear to function as intended, employees must be engaged partners in the safety program. This partnership is built on four key principles of personal responsibility.

Pillar 1: Consistent and Correct Wear

The most advanced safety shoe provides zero protection if it isn't on an employee's foot during a critical moment. Consistency is non-negotiable in designated high-risk areas.

Even a brief moment of exposure, such as quickly entering an area to retrieve a tool, can result in a permanent injury.

Furthermore, correct wear is essential. This includes lacing boots snugly to provide ankle support and ensuring the tongue and gussets are properly aligned to prevent debris or liquids from entering.

Pillar 2: Proactive Maintenance and Inspection

A safety shoe is a piece of critical equipment that endures constant wear and tear. It requires regular inspection by the person who knows it best—the wearer.

Employees should conduct a brief, informal check before each shift. This involves looking for deep cuts, sole separation, exposed steel or composite toes, and excessive tread wear.

Regular cleaning is also part of maintenance. Removing caked-on mud, dirt, or chemicals not only extends the life of the shoe but also makes it easier to spot emerging cracks or defects.

Pillar pillar 3: Immediate Reporting of Defects

Seeing a problem and not reporting it negates the purpose of the entire safety program. A minor defect today can become a catastrophic failure tomorrow.

Employees must feel empowered to report any issues with their footwear without fear of reprisal. A worn-out sole that has lost its slip resistance or a crack near the safety toe compromises the shoe's protective capabilities.

This reporting is a critical data point for safety managers, highlighting potential issues with a specific brand or signaling that a shoe has reached the end of its functional life.

Pillar 4: Active Participation in Training

Safety training is not a passive event; it is the foundation of understanding. It is where employees learn the "why" behind the rules.

Active participation means asking questions and understanding the specific hazards the footwear is designed to protect against, whether they be impact, puncture, electrical shock, or chemical spills.

This knowledge allows employees to recognize when their footwear might be mismatched for a new task or environment, turning them into proactive safety advocates.

Common Pitfalls That Undermine Effectiveness

Even with a well-structured program, certain common behaviors can compromise safety. Recognizing these pitfalls is the first step toward correcting them.

Ignoring Discomfort or Poor Fit

An ill-fitting safety shoe is a major safety risk. Blisters, chafing, and general discomfort can distract a worker and may lead them to modify the shoe or avoid wearing it altogether.

A proper fit is a non-negotiable safety feature. Employees have a responsibility to report fit issues immediately so a better-fitting alternative can be found.

The "It Won't Happen to Me" Mindset

Complacency is the enemy of safety. In routine environments, it is easy for an employee to believe they are immune to risk, leading them to neglect inspections or even forgo wearing their PPE for "quick" tasks.

This mindset is a cultural issue that must be addressed through continuous reinforcement of safety protocols and by sharing stories that illustrate the real-world consequences of a momentary lapse.

Misunderstanding the Shoe's Limitations

Assuming all safety shoes are the same is a critical error. A shoe rated for impact and compression will not protect against electrical hazards unless it is specifically designed to do so.

Employees must understand the specific ratings and limitations of their issued footwear. Using the wrong shoe for the job provides a false and dangerous sense of security.

Making the Right Choice for Your Goal

Fostering a culture of footwear safety requires clear communication and targeted reinforcement. Your approach should align with your primary objective.

- If your primary focus is reducing incidents: Emphasize daily pre-wear inspections and establish a clear, non-punitive process for replacing damaged footwear immediately.

- If your primary focus is improving compliance: Prioritize comfort and proper fit during the selection process to remove the most common barrier to consistent wear.

- If your primary focus is building a long-term safety culture: Invest in training that explains the specific risks in your environment and how the footwear is designed to mitigate them.

Ultimately, a safety shoe is only as effective as the informed and engaged employee who wears it.

Summary Table:

| Pillar of Responsibility | Key Employee Action |

|---|---|

| Consistent & Correct Wear | Wear shoes at all times in designated areas; ensure proper lacing and fit. |

| Proactive Maintenance | Conduct daily pre-shift visual inspections; clean shoes regularly. |

| Immediate Defect Reporting | Report any damage or wear (e.g., sole separation, cracks) immediately. |

| Active Training Participation | Engage in safety training to understand hazards and shoe limitations. |

Equip your workforce with the right foundation for safety. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed for maximum protection and comfort, helping you build a stronger safety culture from the ground up. Contact our experts today to discuss your safety footwear needs and receive a tailored solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How does the perceived value of Safety Shoes influence consumer repeat purchase behavior in the context of design? - 3515

- What primary protective functions do professional safety shoes provide? Essential Industrial Safety Guide

- What are the common workplace dangers that can affect employees' feet? Protect Your Team from Top Hazards

- What is the function of the shank in a safety boot? The Key to Arch Support & Stability

- Why are professional-grade Safety Shoes necessary for forest logging? Guard Against Critical Risks in Forestry Work

- Why are industrial safety boots with high-grip outsoles required for oil leaks and B3 waste? Ensure Worker Stability

- What is dielectric insulation in safety footwear? Essential Protection for High-Voltage Work

- How do professional-grade safety shoes contribute to accident prevention? Reduce Risk with Advanced PPE Footwear