For work boots in demanding environments, a protective agent should be reapplied as often as once a week to twice a month. However, for less intense use, this frequency can extend to every few months. The ideal schedule is not fixed; it is dictated entirely by your working conditions and the visible state of your boots.

Your reapplication schedule for boot protectant should be a response to environmental conditions, not a rigid calendar date. The goal is to re-treat the boots before the protective barrier fails, which depends entirely on the intensity of use.

Why a Fixed Schedule Fails

Treating boot maintenance with a one-size-fits-all approach is a common mistake. The rate at which a protective agent degrades is directly tied to the stress you put on your footwear.

The Role of a Protective Agent

Protective agents, like waterproofing sprays or conditioning waxes, create a barrier on the boot's surface. This barrier repels water, resists stains, and keeps materials like leather from drying out and cracking.

Your Environment is the Key Variable

A boot worn on a construction site with constant exposure to mud, water, and abrasive surfaces will lose its protective coating exponentially faster than one worn in a dry warehouse.

Harsh chemicals, extreme temperatures, and constant flexing of the material all accelerate the breakdown of the protective layer.

Observing the Signs of Wear

Instead of guessing a date, learn to recognize the signs that your boots need attention. This is a far more effective and reliable method of maintenance.

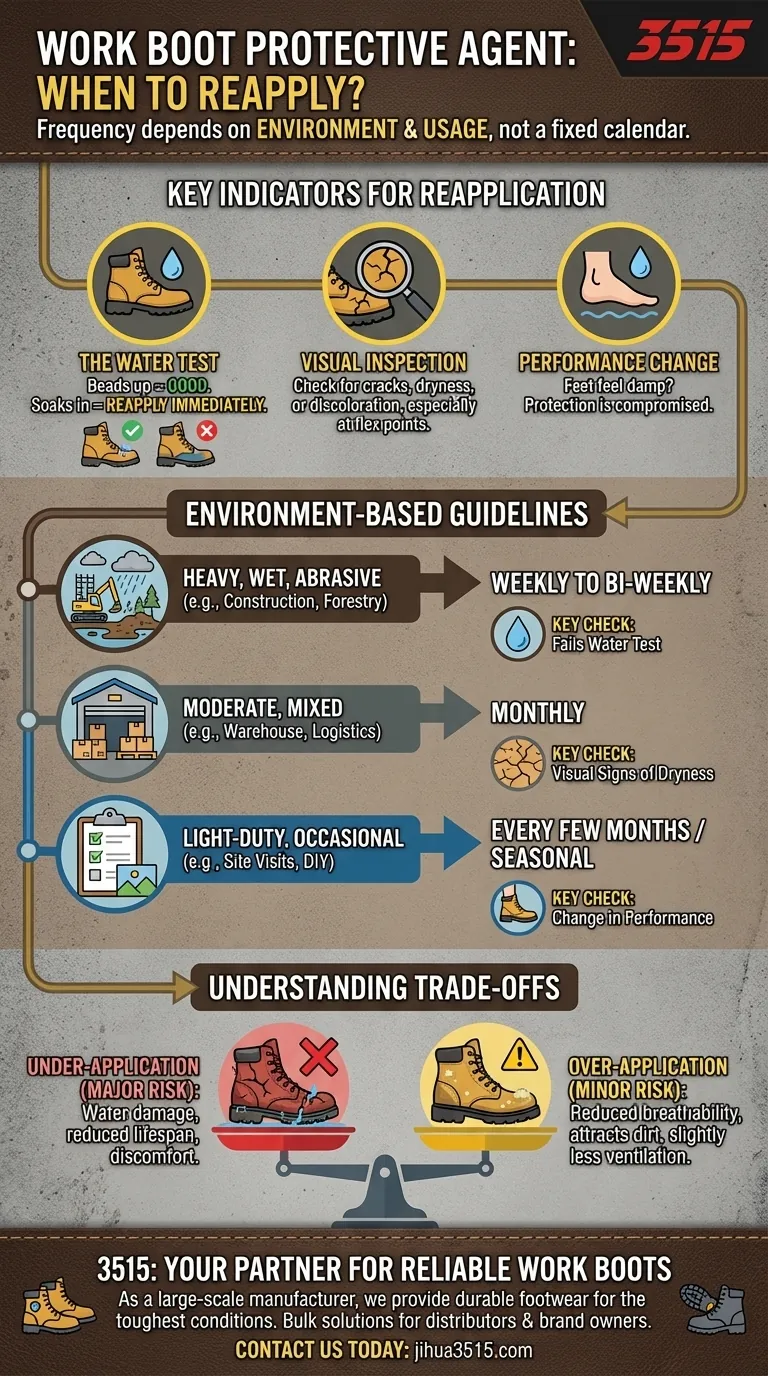

Key Indicators for Reapplication

Your boots will tell you when they need to be re-treated. You just need to know what to look for.

The Water Test

This is the most definitive indicator. Sprinkle a few drops of water on a high-wear area. If the water beads up and rolls off, the protective barrier is still intact.

If the water soaks in and darkens the material (a condition known as "wetting out"), the barrier has failed, and it is time to reapply the agent immediately.

Visual Inspection

Regularly check your boots for signs of dryness or discoloration. For leather boots, look for light-colored or cracked areas, especially along seams and flex points.

A Change in Performance

The simplest indicator is how your feet feel. If you notice even slight dampness after exposure to moisture that your boots previously shed, your protection has been compromised.

Understanding the Trade-offs

Proper application is a balancing act, but the risks are not equal.

The Cost of Under-Application

This is the most significant risk. Failing to reapply a protective agent leads to waterlogged boots, which can cause discomfort, blisters, and potential health issues.

More importantly, it allows moisture and dirt to degrade the boot's materials, drastically shortening their lifespan and compromising their structural integrity.

The Minor Issue of Over-Application

Applying product too frequently or heavily is less of a concern. The main downside is that excess product can clog the pores of breathable materials, slightly reducing ventilation.

In some cases, a thick, waxy buildup can also attract more dirt. However, this is far preferable to the damage caused by under-application.

Making the Right Choice for Your Goal

Base your maintenance schedule on your daily reality, starting with these guidelines and adjusting as needed based on the water test.

- If your primary focus is uptime in heavy, wet, or abrasive conditions (e.g., construction, forestry, plumbing): Start with a weekly or bi-weekly reapplication schedule.

- If your primary focus is reliability in moderate, mixed conditions (e.g., warehouse logistics, general contracting): Plan for a monthly reapplication, checking the condition more often during wet seasons.

- If your primary focus is longevity for occasional or light-duty use (e.g., site visits, weekend projects): Reapply every few months or on a seasonal basis, always checking before exposure to wet weather.

Ultimately, proactive observation is the key to maximizing the performance and lifespan of your work boots.

Summary Table:

| Work Environment | Recommended Reapplication Frequency | Key Indicator |

|---|---|---|

| Heavy, Wet, Abrasive (e.g., Construction) | Once a week to twice a month | Fails the water test |

| Moderate, Mixed (e.g., Warehouse) | Monthly | Visual signs of dryness |

| Light-Duty, Occasional Use | Every few months / Seasonally | Change in performance (feet feel damp) |

Are you a distributor, brand owner, or bulk client in need of reliable, durable work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear designed to withstand the toughest conditions. Our production capabilities encompass all types of safety shoes and work boots, ensuring your workforce is properly equipped.

Let us help you provide high-quality footwear that lasts. Contact our team today to discuss your needs and discover how we can support your business.

Visual Guide

Related Products

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What features are essential in cowboy boots for construction work? Prioritize Certified Safety & Durability

- How long do work boots typically last? Maximize Lifespan & Safety

- What are some alternative footwear options to cowboy boots for farm work? Find the Perfect Fit for Your Farm

- What additional safety features can be found in Chemical Resistant boots? Essential Multi-Hazard Protection

- What are examples of NFPA-approved wildland firefighting boots? Wildlander vs. Linecutter II Compared

- What is the difference between a cowboy boot and a work boot? Choosing the Right Footwear for Your Task

- Why use metal mesh racks for boot disinfection? Essential Tips for Complete Hydrogen Peroxide Sterilization

- Why is comfort important in work shoes? Boost Health, Safety, and Productivity