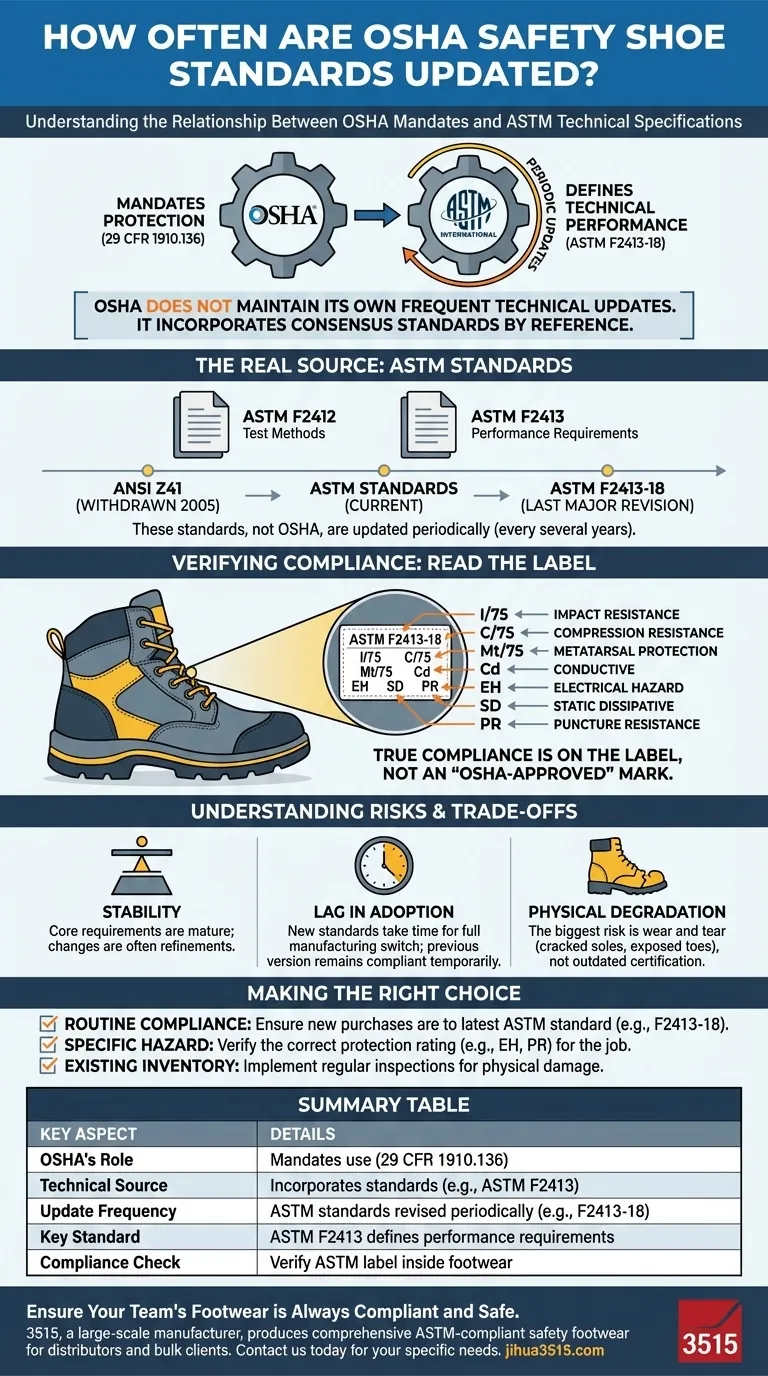

To be direct, OSHA itself does not maintain a frequent, independent update schedule for safety shoe technical specifications. Instead, its regulations for protective footwear (29 CFR 1910.136) incorporate by reference the consensus standards developed by independent organizations. The key is to track updates to these underlying standards, not an "OSHA" update.

The core issue is not how often OSHA changes its own rules, but understanding that OSHA relies on external technical standards from organizations like ASTM International. Therefore, the most important updates to follow are those made to the ASTM standards for footwear, which occur periodically every several years.

The Real Source of Safety Shoe Standards

Many professionals look for an "OSHA-approved" boot, but this is a misconception. OSHA sets the requirement that you must use protective footwear, but it points to other organizations to define how that footwear should perform.

OSHA's Role: The Mandate for Protection

OSHA's primary role is to mandate the use of protective footwear when employees are exposed to hazards. The regulation itself is broad, stating that footwear must be used whenever there is a danger of foot injuries.

The Technical Authorities: ASTM and ANSI

The detailed technical specifications—the "how"—come from consensus-based standards organizations. The two most important are:

- ASTM International (formerly American Society for Testing and Materials): Publishes ASTM F2412 (Standard Test Methods for Foot Protection) and ASTM F2413 (Standard Specification for Performance Requirements for Protective Toe Cap Footwear).

- American National Standards Institute (ANSI): While previously dominant, the ANSI Z41 standard was withdrawn in 2005 and replaced by the ASTM standards.

These ASTM standards are the ones that are updated periodically. For example, a common standard cited is ASTM F2413-18, with the "18" indicating the year of its last major revision (2018).

How to Verify Compliance on Your Footwear

True compliance is verified not by an OSHA logo, but by reading the specific code printed on a label inside the shoe. This label is your guarantee that the footwear meets the required technical standard.

Reading the ASTM Label

A compliant label will have a specific format. It will clearly state the standard it meets, such as ASTM F2413-18.

Following the standard, you will see codes for the specific protections the shoe offers. These include ratings for:

- Impact Resistance (I/75)

- Compression Resistance (C/75)

- Metatarsal Protection (Mt/75)

- Conductive Properties (Cd)

- Electrical Hazard Protection (EH)

- Static Dissipative Properties (SD)

- Puncture Resistance (PR)

Understanding the Trade-offs and Risks

While the core standards are stable, misunderstanding the update cycle can lead to compliance gaps or a false sense of security.

The Stability of Core Requirements

The fundamental requirements for impact and compression resistance on safety toes are mature and do not change dramatically with every revision. An update may refine testing methods or add new classifications, but the core principles remain consistent.

The Lag in Adoption

There can be a delay between when ASTM releases a new standard (e.g., a hypothetical "F2413-25") and when manufacturers have fully switched production. For a time, footwear certified to the previous standard (F2413-18) will still be compliant and available.

The Real Risk: Physical Degradation

The more immediate risk to worker safety is rarely a minor standard update. It is the physical degradation of the footwear. A boot certified to the latest standard is useless if the sole is cracked, the steel toe is exposed, or its EH properties have been compromised by excessive moisture.

Making the Right Choice for Your Workplace

Focus on the specific hazard and the standard listed on the equipment, not just a generic "OSHA" requirement.

- If your primary focus is routine compliance: Ensure all new footwear purchases are certified to the latest active ASTM standard, currently ASTM F2413-18.

- If your primary focus is managing a specific hazard: Look beyond the general standard and verify the specific protection rating (e.g., EH for electricians, PR for construction) is present on the footwear's label.

- If your primary focus is managing existing inventory: Implement a regular inspection policy for wear and tear, as physical damage is a more frequent cause of failure than an outdated certification.

Ultimately, verifying the specific ASTM standard on the label is the most direct path to ensuring both worker safety and regulatory compliance.

Summary Table:

| Key Aspect | Details |

|---|---|

| OSHA's Role | Mandates use of protective footwear (29 CFR 1910.136). |

| Technical Source | Incorporates standards by reference (e.g., ASTM F2413). |

| Update Frequency | ASTM standards are revised periodically (e.g., F2413-18). |

| Key Standard | ASTM F2413 defines performance requirements (I/75, C/75, EH, etc.). |

| Compliance Check | Verify the ASTM label inside the footwear, not an "OSHA-approved" mark. |

Ensure Your Team's Footwear is Always Compliant and Safe

Navigating safety standards can be complex, but having a reliable manufacturing partner shouldn't be. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring your procurement is hassle-free and fully compliant with the latest standards.

Let us help you protect your workforce efficiently.

Contact us today to discuss your specific needs and get a quote for certified, durable safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture