With proper care and routine maintenance, a high-quality pair of fire boots can last for several years of active service. The actual lifespan is not a fixed number but a direct result of the boot's initial quality, the intensity of its use, and the consistency of the care it receives.

The longevity of your fire boots is an equation: Initial build quality plus consistent, diligent maintenance determines their ultimate service life. Neglecting either factor significantly shortens their lifespan and compromises your safety.

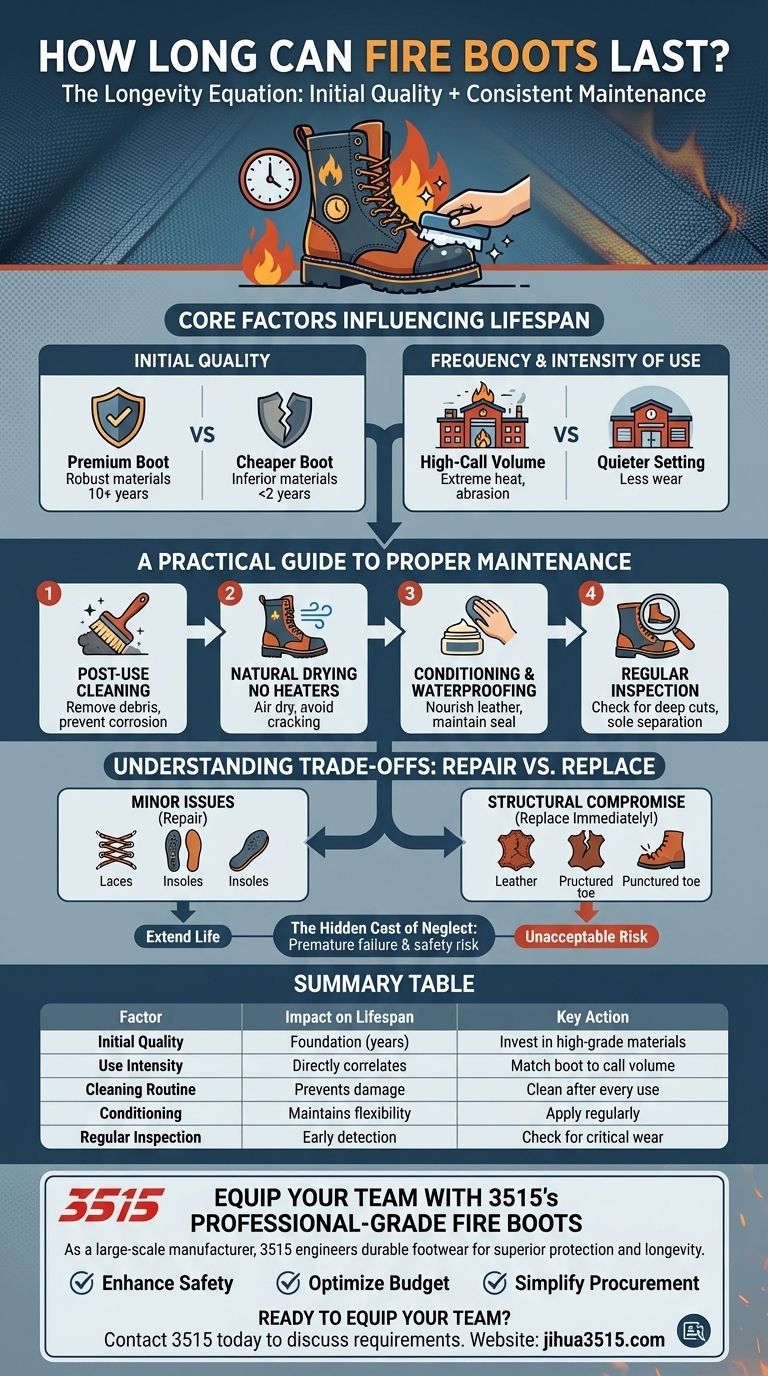

The Core Factors Influencing Lifespan

A boot's durability is determined long before its first fire. Several key variables dictate how long it will reliably protect you.

The Critical Role of Initial Quality

The materials and construction of the boot are the foundation of its longevity. A premium boot made with high-grade, durable leather and robust stitching can potentially last for a decade or more with proper care.

In contrast, cheaper boots often use inferior materials that break down quickly, with waterproofing sometimes failing within a year or two, regardless of maintenance.

Frequency and Intensity of Use

A boot's service life is directly related to its time on the job. Boots used in a high-call-volume urban department will face more wear and tear than those used in a quieter, rural setting.

Exposure to extreme heat, water, chemicals, and physical abrasion all contribute to the degradation of the boot's materials over time.

A Practical Guide to Proper Maintenance

Consistent care is not just about appearances; it is a critical safety function that ensures the boot performs as designed.

Post-Use Cleaning Routine

After every use, you must remove all soot, mud, and other debris from your boots. This prevents corrosive materials from degrading the leather and seams.

The Importance of Natural Drying

Always allow boots to air dry naturally in a cool, dry place. Using direct heat sources like heaters or blow dryers can cause the leather to dry out too quickly, leading to cracking and compromising its protective qualities.

Conditioning and Waterproofing

Leather requires regular conditioning to maintain its flexibility and water resistance. Apply a quality leather conditioner or waterproofing treatment according to the manufacturer's recommendations to nourish the material.

The Habit of Regular Inspection

Make it a habit to regularly inspect your boots for any signs of damage. Look for deep cuts, cracks in the leather, separation of the sole, or damaged stitching. Early detection of a problem can prevent a catastrophic failure.

Understanding the Key Trade-offs

Even the best boots have limitations. Knowing when to repair and when to retire a boot is a crucial safety decision.

When to Repair vs. Replace

Minor issues, such as worn-out laces or insoles, are simple fixes. Major repairs, like resoling or "rebuilds," can extend a boot's life.

However, if the core structure of the boot is compromised—such as cracked leather, heat damage, or a punctured safety toe—it must be replaced immediately. A repair cannot restore its original protective integrity.

The Hidden Cost of Neglect

Forgoing a consistent maintenance schedule is a costly mistake. It not only leads to the premature failure of an expensive piece of equipment but, more importantly, it puts the user at an unacceptable risk of injury.

How to Apply This to Your Goal

Your approach to boot longevity should align with your primary objective, whether it's maximizing safety or budget.

- If your primary focus is maximum safety: Implement a rigorous, documented inspection schedule and adopt a conservative replacement policy, retiring boots at the first sign of significant wear or structural compromise.

- If your primary focus is cost-effectiveness: Invest in high-quality boots from a reputable manufacturer upfront and enforce a strict, mandatory maintenance protocol to maximize their service life.

Ultimately, treating your fire boots as the critical piece of life-safety equipment they are is the only way to ensure they protect you when it matters most.

Summary Table:

| Factor | Impact on Lifespan | Key Action |

|---|---|---|

| Initial Quality | Foundation for longevity (years) | Invest in high-grade materials |

| Use Intensity | Directly correlates with wear | Match boot to call volume/environment |

| Cleaning Routine | Prevents corrosive damage | Clean after every use |

| Conditioning | Maintains flexibility & waterproofing | Apply conditioner regularly |

| Regular Inspection | Early detection of critical wear | Check for cracks, sole separation, damage |

Ensure your team's safety and maximize equipment value with 3515's professional-grade fire boots.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our boots are engineered for superior protection and longevity, built to withstand the most demanding conditions.

We help you:

- Enhance Safety: Protect your personnel with reliable, high-performance gear.

- Optimize Budget: Durable construction reduces long-term replacement costs.

- Simplify Procurement: A single source for all your footwear needs.

Ready to equip your team with boots built to last? Contact 3515 today to discuss your requirements and receive a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What type of sole is used in wildland firefighter boots and why? Essential Heat-Resistant Lug Soles

- What are some common safety risks associated with inadequate work boots? Protect Your Workforce from the Ground Up

- Why is wearing proper construction footwear important in accident-prone job sites? Protect Your Workforce

- What are the key features for warehouse and logistics work boots? Ensure Safety and All-Day Comfort

- What are some tips for maintaining work boots? Extend Lifespan & Maximize Performance

- What are some key differences between traditional and modern engineer boots? Choose the Right Style for Your Needs

- How does the boot's waterproofing system work? A Guide to Staying Dry

- How do fire departments select boots? A Guide to Rigorous Field Testing and NFPA Standards