To be considered high-quality, an oil-resistant safety boot undergoes a rigorous series of standardized tests. These evaluations focus on two primary areas: the boot's structural integrity under physical stress (like impacts and punctures) and the material resilience of its components, particularly the sole, against chemical degradation from oil and other solvents.

The true measure of an oil-resistant boot is not just its ability to prevent slips, but its capacity to maintain its protective features and structural integrity even after prolonged exposure to corrosive oils and chemicals.

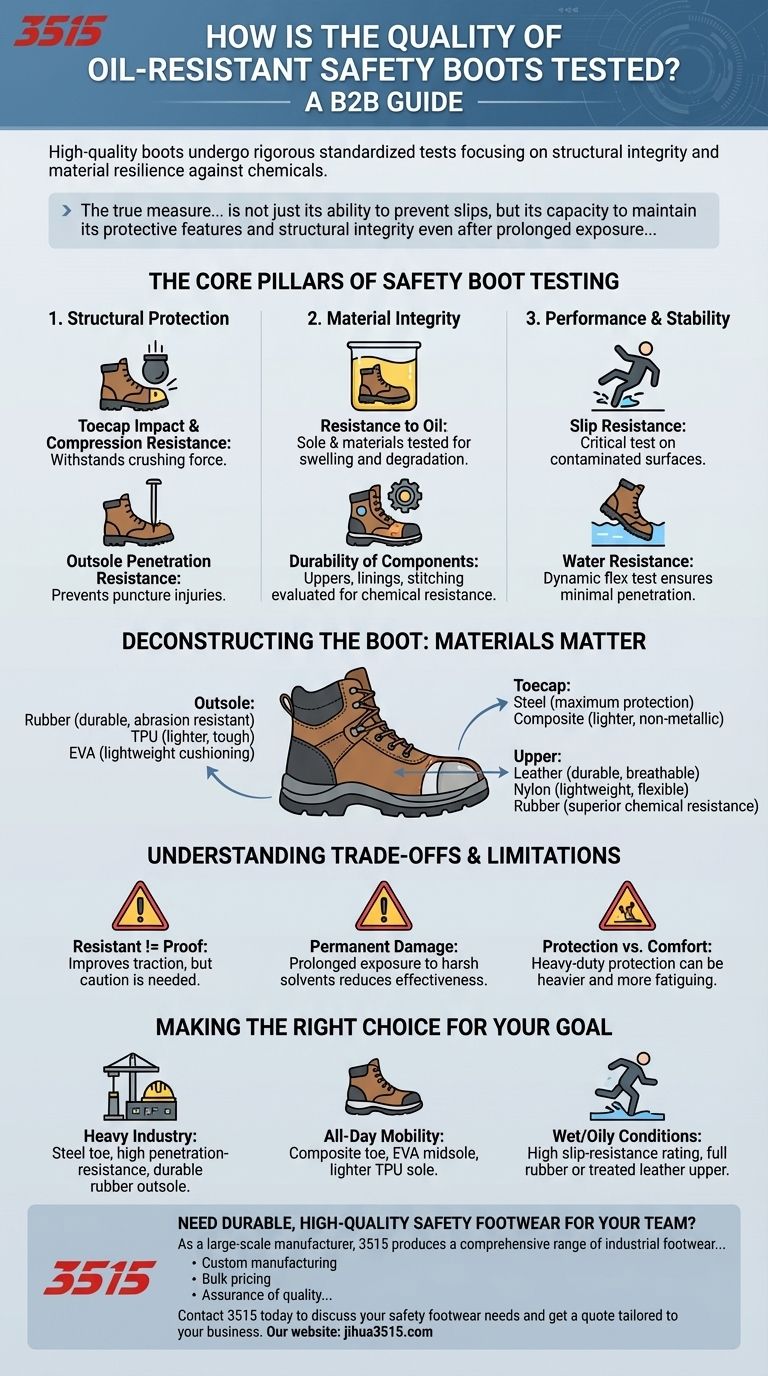

The Core Pillars of Safety Boot Testing

Quality assurance for safety footwear is a multi-faceted process designed to simulate the real-world hazards a worker might face. The tests can be broken down into three critical categories.

1. Assessing Structural Protection

These tests evaluate the boot's ability to protect you from direct physical threats in the workplace.

- Toecap Impact Resistance: A weight is dropped onto the protective toecap to ensure it can withstand a significant impact without crushing or deforming to a point that would injure the foot.

- Toecap Compression Resistance: The toecap is subjected to a heavy rolling or compressive force to verify its ability to protect against crushing injuries, such as from a vehicle wheel.

- Outsole Penetration Resistance: A sharp object, like a nail, is pressed into the sole of the boot with a specified force to ensure it cannot puncture through and injure the foot.

2. Verifying Material Integrity

This is what truly defines an "oil-resistant" boot. The focus is on how the boot's materials, especially the outsole, react to chemical exposure.

- Resistance to Oil: The sole material is exposed to oil, often at elevated temperatures, for a set period. Testers then check for changes in volume (swelling), hardness, or any other signs of degradation. A high-quality boot will show minimal change, retaining its shape and function.

- Durability of Components: The upper material, linings, and even the stitching are evaluated for their ability to resist damage from oil, ensuring the entire boot remains a cohesive protective unit.

3. Evaluating Performance and Stability

Beyond withstanding damage, the boot must perform its primary function of keeping you stable and safe on your feet.

- Slip Resistance: This is one of the most critical tests for boots used in oily environments. The boot is tested on various surfaces coated with contaminants (like oil or water) to measure its coefficient of friction and ability to prevent slips.

- Water Resistance (If Applicable): For boots rated as waterproof, a dynamic water flex test is performed. The boot is submerged and repeatedly flexed to simulate walking, ensuring minimal water penetration over time.

Deconstructing the Boot: Materials Matter

The materials chosen for each part of the boot are critical to passing these tests and providing reliable protection.

The Outsole: Your First Line of Defense

- Rubber: An excellent choice known for its high resistance to both oil and abrasion, providing durable traction.

- Thermo-Polyurethane (TPU): A modern material that is lighter than rubber but still offers outstanding durability and oil resistance.

- Ethylene-Vinyl Acetate (EVA): Often used in the midsole for its lightweight cushioning and shock absorption, contributing to comfort and stability.

The Toecap: Choosing Your Protection

- Steel: The traditional standard for maximum impact and compression protection, though it is heavier and conducts temperature.

- Composite: A lighter, non-metallic alternative made from materials like Kevlar or carbon fiber. It provides excellent structural integrity without the weight or conductivity of steel.

The Upper: Balancing Durability and Breathability

- Leather: A classic choice that offers natural durability, breathability, and comfort.

- Nylon: Often used in combination with other materials to create a lightweight, flexible, and breathable upper.

- Rubber: Provides superior water and chemical resistance, making it ideal for extremely wet or contaminated environments.

Understanding the Trade-offs and Limitations

Even the highest-quality boot has its limits. Understanding these is key to maintaining safety.

"Resistant" Does Not Mean "Proof"

An oil-resistant, non-slip sole dramatically improves traction, but it cannot guarantee you will never slip in extremely slick conditions. Proper caution is always necessary.

Contaminants Can Cause Permanent Damage

While the sole is designed to resist oil, prolonged exposure to harsh solvents or chemicals can permanently damage its non-slip surface, reducing its effectiveness over time.

The Balance of Protection and Comfort

There is often a trade-off between features. A heavy-duty steel toe and thick rubber sole offer maximum protection but can be heavy and fatiguing for all-day wear compared to a lighter composite toe and TPU sole.

Making the Right Choice for Your Goal

Select your boot based on a clear understanding of your work environment's specific hazards.

- If your primary focus is maximum protection in heavy industry: Prioritize a boot with a steel toe, a high penetration-resistance rating, and a durable rubber outsole.

- If your primary focus is all-day mobility and comfort with moderate risk: Look for a boot with a composite toe, an EVA midsole for shock absorption, and a lighter TPU sole.

- If your primary focus is working in constantly wet or oily floor conditions: Insist on a boot with a high-grade slip-resistance rating and consider a full rubber or specially treated leather upper.

Understanding how a safety boot is tested empowers you to look beyond marketing claims and choose footwear that provides true, reliable protection for your specific needs.

Summary Table:

| Test Category | Key Tests | Purpose |

|---|---|---|

| Structural Protection | Toecap Impact/Compression, Outsole Penetration | Ensure boot withstands physical hazards like crushing and punctures. |

| Material Integrity | Resistance to Oil, Durability of Components | Verify materials resist chemical degradation from oils and solvents. |

| Performance & Stability | Slip Resistance, Water Resistance | Confirm boot maintains stability and traction in hazardous conditions. |

Need Durable, High-Quality Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, rigorously tested to meet the highest standards for oil resistance, structural integrity, and slip resistance.

We provide:

- Custom manufacturing tailored to your specific safety requirements.

- Bulk pricing for distributors and large-volume buyers.

- Assurance of quality backed by standardized testing protocols.

Contact 3515 today to discuss your safety footwear needs and get a quote tailored to your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the main types of safety toe shoes? Choose the Right Protection for Your Job

- How do S4 safety boots differ from S1 safety shoes? Choose the right protection for wet or dry work.

- Are steel toe and composite toe shoes the only safety shoe options? Discover the third type.

- What materials should a good safety shoe include? The Ultimate Guide to Protective Footwear

- How does the Factorial Survey method function in safety footwear evaluation? Optimize Your Product Performance

- Why is it necessary to clean safety boots and protective clothing immediately? Prevent Deadly Chemical Exposure Now

- How do Intelligent Tags in Safety Shoes ensure compliance? Revolutionize Workplace Safety with Real-Time PPE Verification

- Why is footwear choice considered important in personal protection equipment? Ensure Safety from the Ground Up