A vulcanized outsole is constructed by molding raw rubber using heat and pressure, then permanently bonding it to the shoe's upper in a high-temperature oven. This process essentially melts and fuses the rubber outsole, a reinforcing rubber strip called foxing tape, and the upper into a single, unified piece.

The key to understanding vulcanized construction is that it's not simply gluing parts together. It is a chemical process that uses intense heat to cure and fuse rubber components, creating a uniquely flexible and integrated sole that is chemically bonded to the shoe.

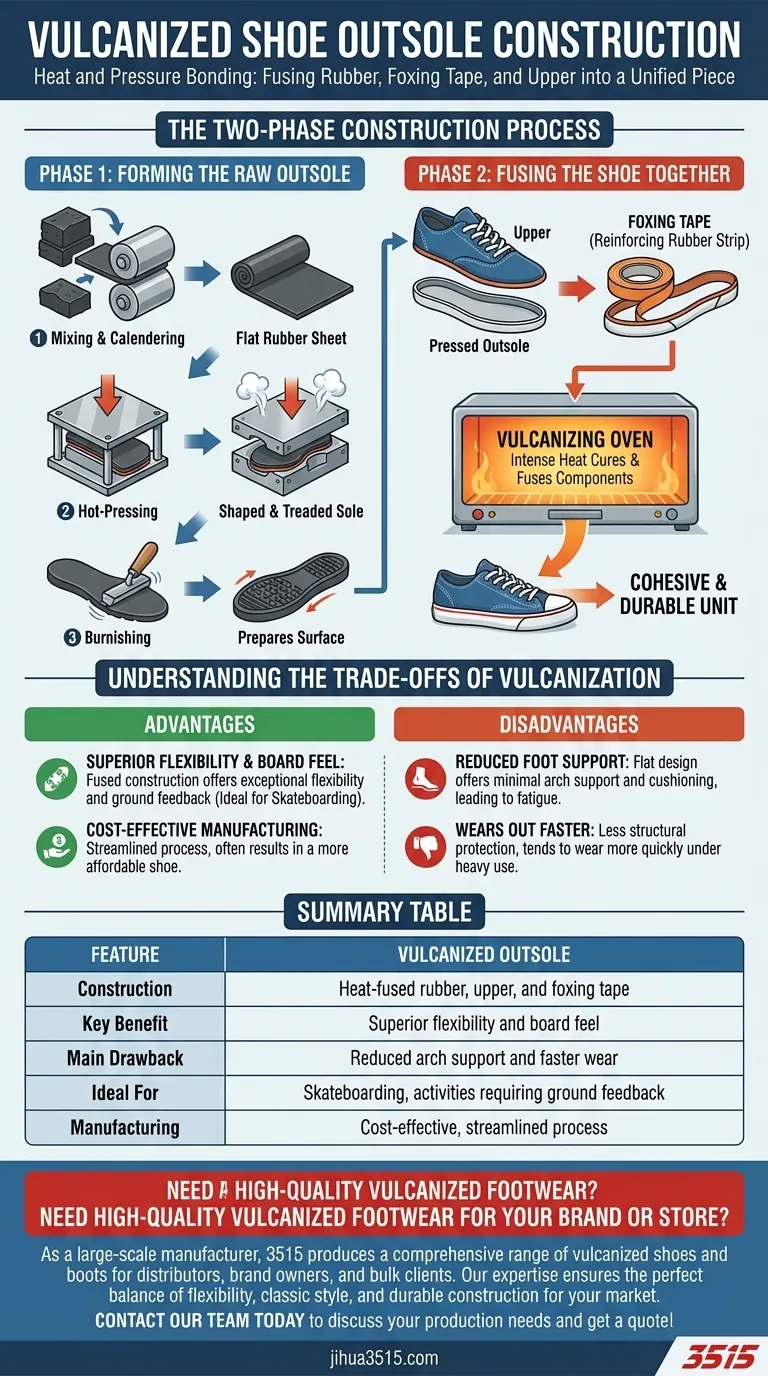

The Two-Phase Construction Process

The creation of a vulcanized shoe's outsole happens in two distinct phases: first, the sole is created, and second, it is fused to the rest of the shoe.

Phase 1: Forming the Raw Outsole

This initial stage turns raw rubber into the recognizable bottom of a shoe.

Step 1: Mixing and Calendering

First, raw rubber is mixed to achieve the desired properties. This mixture is then fed through rollers in a process called calendering, which presses it into a consistent, flat rubber sheet.

Step 2: Hot-Pressing

The rubber sheet is then placed into a mold and subjected to intense heat and pressure. This hot-pressing step simultaneously shapes the sole, creates its tread pattern, and begins the curing (hardening) process.

Step 3: Burnishing

After being pressed, the sole is burnished or trimmed. This removes any excess rubber and prepares its surface for bonding with the shoe's upper.

Phase 2: Fusing the Shoe Together

This is the defining stage where the shoe gets its unique vulcanized character.

The Role of Foxing Tape

A strip of extruded rubber, known as foxing tape, is wrapped around the seam where the upper meets the flat outsole. This tape is crucial for strengthening the final bond and giving the shoe its classic look.

The Final Vulcanizing Oven

The entire shoe assembly—the upper, the pressed outsole, and the foxing tape—is placed in a vulcanizing oven. The heat activates a chemical reaction that cures all the rubber components and bonds them together into one cohesive and durable unit.

Understanding the Trade-offs of Vulcanization

The vulcanization process directly impacts a shoe's performance, durability, and cost. It is a method with clear advantages and disadvantages.

Advantage: Superior Flexibility and Board Feel

Because the outsole is fused directly to the upper without heavy adhesives or stitching, the final product is exceptionally flexible. This gives the wearer, particularly skateboarders, an excellent "board feel" and direct feedback from the ground.

Advantage: Cost-Effective Manufacturing

Vulcanization is a streamlined and relatively simple manufacturing process compared to alternatives like stitched cupsoles. This often results in a more affordable shoe.

Disadvantage: Reduced Foot Support

The flat, flexible design offers minimal arch support and cushioning. This can lead to foot fatigue during long periods of wear or high-impact activities.

Disadvantage: Wears Out Faster

The same flexibility that provides great board feel also means the shoe offers less structural protection. Vulcanized shoes tend to wear out more quickly, especially under heavy use, compared to more robust construction methods.

Making the Right Choice for Your Goal

Selecting a shoe with a vulcanized outsole depends entirely on your priorities for performance, comfort, and durability.

- If your primary focus is board feel and flexibility: The vulcanized outsole is the definitive choice for activities like skateboarding where ground feedback is critical.

- If your primary focus is all-day comfort and impact protection: A shoe with a cupsole construction, which is stitched or glued on, will provide superior cushioning and support.

- If your primary focus is affordability and classic style: Vulcanized shoes deliver a timeless look and are often the most budget-friendly option available.

Ultimately, choosing a vulcanized shoe is a conscious trade-off that prioritizes flexibility and ground-feel over structured support and long-term durability.

Summary Table:

| Feature | Vulcanized Outsole |

|---|---|

| Construction | Heat-fused rubber, upper, and foxing tape |

| Key Benefit | Superior flexibility and board feel |

| Main Drawback | Reduced arch support and faster wear |

| Ideal For | Skateboarding, activities requiring ground feedback |

| Manufacturing | Cost-effective, streamlined process |

Need high-quality vulcanized footwear for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures the perfect balance of flexibility, classic style, and durable construction for your market.

Contact our team today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained