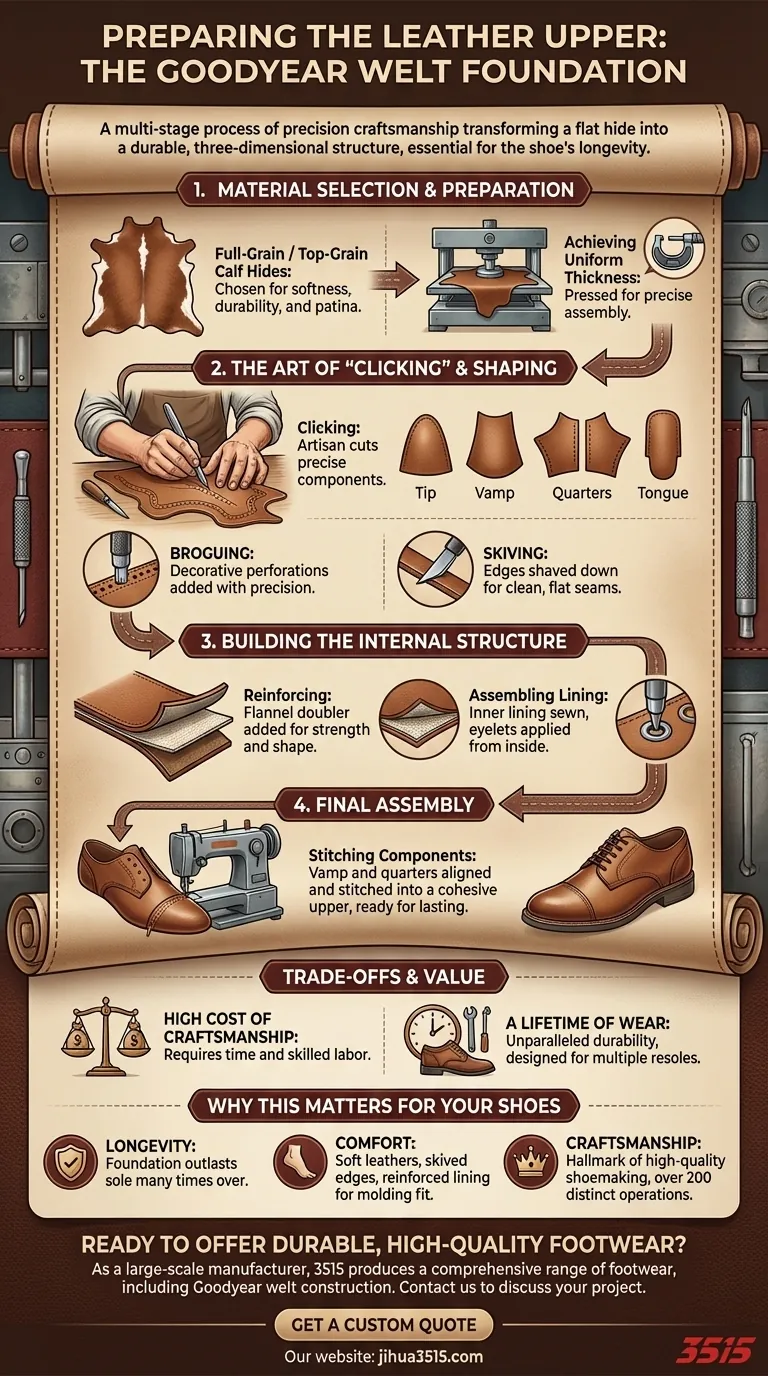

In Goodyear welt construction, preparing the leather upper is a multi-stage process of precision craftsmanship that transforms a flat hide into a durable, three-dimensional structure. It involves carefully selecting and pressing the leather, cutting the individual components, adding details like broguing, and meticulously assembling the pieces with internal reinforcements before the upper is complete.

The preparation of the upper is not merely about cutting leather; it's a deliberate system of both shaping and reinforcing. This process ensures the upper has the structural integrity to outlast multiple resoles, which is the core principle of a Goodyear welted shoe.

The Foundation: Material Selection and Preparation

The entire process begins with the most critical component: the leather itself. The choice of material dictates the shoe's final appearance, comfort, and, most importantly, its lifespan.

Choosing the Right Hide

High-quality uppers are typically cut from full-grain or top-grain calf hides. This leather is chosen for its unique combination of softness, durability, and ability to develop a rich patina with age. It must be supple enough to mold to the foot yet strong enough to withstand years of stress.

Achieving Uniform Thickness

Before any cutting begins, the selected hides are pressed to a perfectly uniform thickness. This step is crucial for ensuring that every component of the shoe fits together precisely and that there are no unexpected variations during assembly.

The Art of "Clicking": Shaping the Upper

This stage is where the skill of the artisan becomes most apparent. A craftsman, known as a "clicker," transforms the prepared hide into the precise pieces that will form the shoe.

The Craftsman's Cut

Using sharp patterns, the clicker carefully cuts out the primary parts of the upper. These typically include the tip, vamp (the front section), quarters (the sides and back), and the tongue. Each cut is deliberate to maximize the quality of the hide and ensure the grain runs correctly.

Precision in the Details

After the main pieces are cut, decorative elements are added. This includes punching the characteristic perforations known as brogue holes. This is a functional art, requiring a steady hand and an eye for symmetry.

Skiving the Edges

The edges of each leather piece are carefully shaved down, or skived. This thinning process is critical for creating clean, flat seams. Without skiving, overlapping layers of leather would create bulky, uncomfortable ridges inside the shoe.

Building the Internal Structure

A high-quality upper is more than just the exterior leather. An internal structure is built simultaneously to provide support, comfort, and durability from within.

Reinforcing for Strength

A flannel doubler or similar reinforcement is often glued to the inside of the main leather pieces. This adds structure and support to high-stress areas, helping the shoe maintain its shape over time without adding significant bulk.

Assembling the Lining

The shoe's inner lining is sewn together separately. The eyelets for the laces are applied from the inside of the lining at this stage, ensuring a smooth finish against the foot.

Final Assembly: From Pieces to a Whole

With all individual components prepared, the final step is to bring them together into a single, cohesive unit.

Stitching the Components

The vamp and the quarters are carefully aligned and stitched together. This is the final primary operation that completes the upper, making it ready for the lasting process, where it will be stretched over a mold to give the shoe its final shape. The entire process involves over 200 distinct operations to create a single pair.

Understanding the Trade-offs

The meticulous nature of this process comes with clear advantages and a primary disadvantage.

The High Cost of Craftsmanship

This detailed, multi-step preparation requires significant time and highly skilled labor. The precision cutting, skiving, and reinforcement cannot be rushed, which directly contributes to the higher cost of Goodyear welted footwear.

The Payoff: A Lifetime of Wear

The trade-off for the high initial cost is unparalleled durability. The upper is intentionally over-engineered to be a permanent foundation. This ensures it can easily withstand the stress of multiple resolings, making the shoe a long-term, repairable investment rather than a disposable item.

Why This Process Matters for Your Shoes

Understanding how the upper is prepared helps you appreciate the true value of your footwear.

- If your primary focus is longevity: The detailed upper preparation is an assurance that the shoe's foundation can outlast its sole many times over, making it a sound long-term investment.

- If your primary focus is comfort: The careful selection of soft leathers, skived edges, and reinforced lining creates an upper that will mold to your foot without bulky or irritating seams.

- If your primary focus is craftsmanship: This multi-stage process, from hand-guided cutting to hidden internal reinforcements, is a clear hallmark of high-quality shoemaking.

Knowing these steps transforms a simple shoe into a piece of functional art, built with integrity from the inside out.

Summary Table:

| Preparation Stage | Key Action | Purpose |

|---|---|---|

| Material Selection | Choosing full-grain/top-grain calf hide | Ensures durability, softness, and a rich patina |

| Clicking (Cutting) | Precise cutting of components (vamp, quarters) | Maximizes hide quality and ensures correct grain direction |

| Skiving | Shaving down the edges of leather pieces | Creates clean, flat seams for interior comfort |

| Internal Reinforcement | Adding flannel doublers and assembling the lining | Provides structural support and maintains shape |

| Final Assembly | Stitching components together | Creates a cohesive upper ready for lasting |

Ready to Offer Durable, High-Quality Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those built with the durable Goodyear welt construction.

We can help you deliver the superior craftsmanship and longevity your customers expect. Contact us today to discuss your manufacturing needs and how we can bring value to your product line.

Get a Custom Quote & Discuss Your Project

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

People Also Ask

- What are the characteristics of business casual sneakers? Master the Polished & Professional Look

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style

- What are the key features of high-quality leather in shoes? Invest in Durability and a Perfect Fit

- How does top-grain leather differ from full-grain? Choose the Right Leather for Your Products

- Can sneakers be part of a business casual wardrobe? Yes, with the right style and fit