At its core, Polyvinyl Chloride (PVC) is produced through a multi-stage chemical process that starts with two simple, abundant raw materials. The process uses chlorine, which is derived from common industrial-grade salt, and ethylene, which is extracted from petroleum or natural gas. These ingredients are chemically synthesized to create a monomer, which is then converted into the final, stable polymer resin.

PVC's production method is unique among major plastics because it is significantly less dependent on crude oil. The process starts by combining chlorine (from salt) and ethylene (from fossil fuels) to create a vinyl chloride monomer, which is then polymerized into the raw PVC resin.

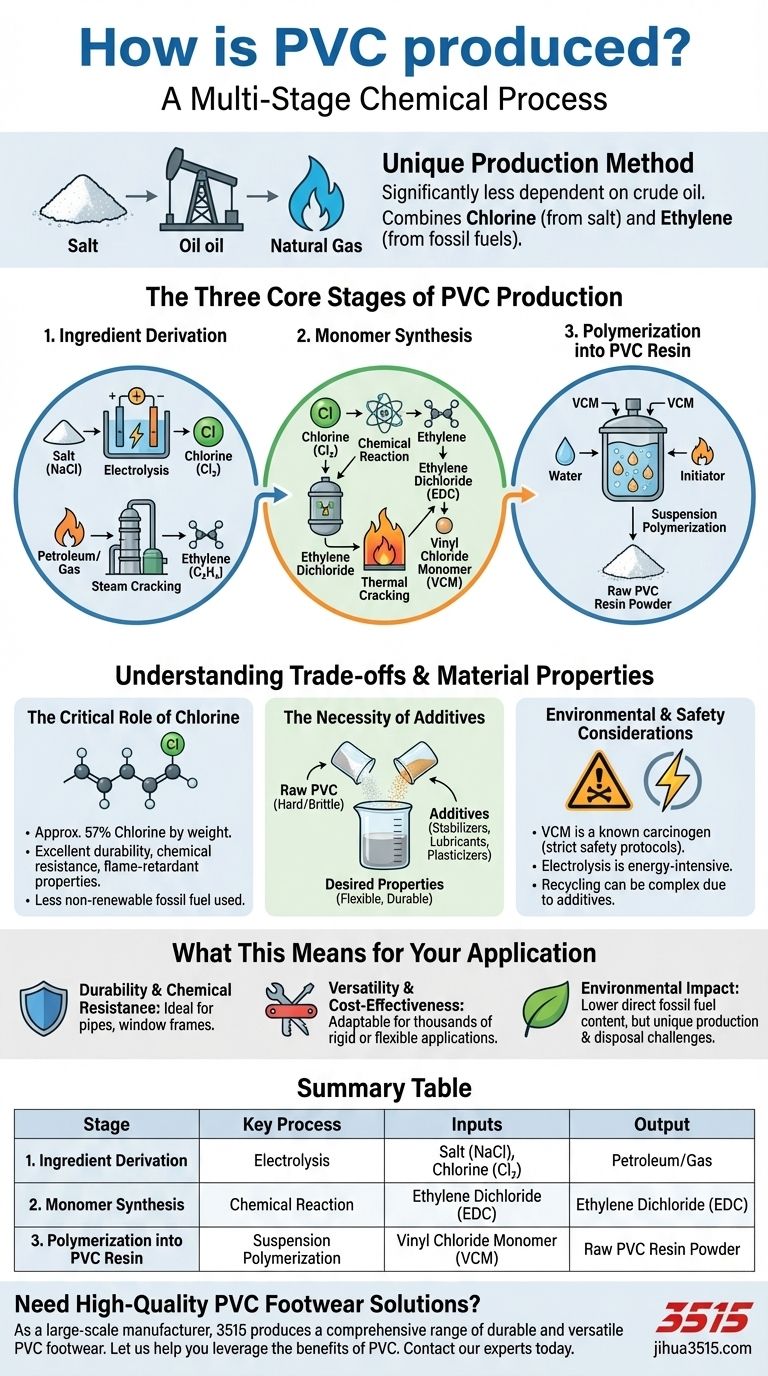

The Three Core Stages of PVC Production

The transformation from raw materials into a finished PVC resin is a sophisticated engineering process. It can be understood by breaking it down into three primary stages: obtaining the ingredients, synthesizing the monomer, and creating the final polymer.

Step 1: Deriving the Key Ingredients

Before PVC can be made, its two fundamental chemical building blocks must be produced.

First, chlorine is isolated from salt (NaCl) through a process called electrolysis. An electrical current is passed through a saltwater solution, separating it into chlorine, sodium hydroxide, and hydrogen.

Second, ethylene (C₂H₄) is produced from hydrocarbons. This is typically done through a high-temperature process known as steam cracking, which breaks down feedstocks like ethane (from natural gas) or naphtha (from petroleum).

Step 2: Synthesizing the Monomer (VCM)

With the two primary ingredients ready, they are combined to create the essential building block for PVC.

Chlorine and ethylene are reacted together to produce Ethylene Dichloride (EDC). This intermediate compound is then heated to extremely high temperatures in a furnace, a process called thermal cracking.

This high-heat process cracks the EDC molecule, transforming it into Vinyl Chloride Monomer (VCM)—the fundamental molecule that will form the final plastic.

Step 3: Polymerization into PVC Resin

The final step is to link the individual VCM molecules together into long, stable chains.

This is achieved through polymerization. The most common method is suspension polymerization, where the VCM monomer is suspended as droplets in water inside a reactor. Under pressure and with the help of an initiating chemical, the VCM molecules link together.

The result of this process is a stable, inert white powder known as PVC resin. This raw resin is the base material that is later compounded with additives to create finished products.

Understanding the Trade-offs and Material Properties

The unique production path of PVC directly influences its properties, benefits, and challenges. Understanding this context is crucial for evaluating the material.

The Critical Role of Chlorine

PVC is approximately 57% chlorine by weight. This high chlorine content is what gives the material its excellent durability, chemical resistance, and inherent flame-retardant properties. It also means PVC uses significantly less non-renewable fossil fuel per pound than other common plastics like polyethylene or polypropylene.

The Necessity of Additives

Raw PVC resin in its pure powder form is hard and brittle. It is almost never used without being compounded with a range of additives to achieve the desired properties for a final product.

Common additives include stabilizers to protect against heat and UV degradation, lubricants to aid in processing, and plasticizers (like phthalates) to make the material flexible for applications like flooring, cables, and roofing membranes.

Environmental and Safety Considerations

The production process involves hazardous chemicals. VCM is a known carcinogen and its handling is subject to extremely strict safety protocols to prevent worker exposure and environmental release.

Furthermore, the electrolysis process to produce chlorine is energy-intensive. While PVC is technically recyclable, the wide variety of additives used in different products can make the recycling process complex.

What This Means for Your Application

Understanding how PVC is made allows you to make more informed decisions about where and why to use it.

- If your primary focus is durability and chemical resistance: PVC's chlorine-based structure makes it exceptionally resistant to acids, alkalis, and weathering, ideal for pipes and window frames.

- If your primary focus is versatility and cost-effectiveness: The ability to modify PVC with additives allows it to be formulated for thousands of rigid or flexible applications, making it one of the most adaptable and economical polymers.

- If your primary focus is environmental impact: Acknowledge that while PVC's reliance on salt reduces its direct fossil fuel content, its production and disposal cycles present unique challenges that must be considered.

Understanding this production pathway from salt and ethylene is the key to appreciating both PVC's remarkable versatility and its complex lifecycle.

Summary Table:

| Stage | Key Process | Inputs | Output |

|---|---|---|---|

| 1. Ingredient Derivation | Electrolysis & Steam Cracking | Salt (NaCl), Petroleum/Gas | Chlorine, Ethylene |

| 2. Monomer Synthesis | Chemical Reaction & Thermal Cracking | Chlorine, Ethylene | Vinyl Chloride Monomer (VCM) |

| 3. Polymerization | Suspension Polymerization | VCM | Raw PVC Resin Powder |

Need High-Quality PVC Footwear Solutions?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and versatile PVC footwear for distributors, brand owners, and bulk clients. Our expertise in material science ensures optimal performance for your specific application.

Let us help you leverage the benefits of PVC:

- Durability & Chemical Resistance: Ideal for industrial and safety footwear.

- Cost-Effectiveness & Versatility: Perfect for a wide range of consumer and specialized products.

Contact our experts today to discuss your custom footwear needs and discover how our production capabilities can bring your product vision to life.

Visual Guide

Related Products

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What is the overall importance of wearing the right shoes? Protect Your Health & Performance

- What is the actual mechanism of breathability in footwear? The Science of Moving Moisture Out

- Why use GC-FID for measuring benzene in footwear manufacturing? Ensure High Accuracy in Complex VOC Environments

- What is the purpose of applying professional signal processing to physiological data in footwear fatigue tests?

- What types of socks are recommended for winter cycling? Stay Warm & Dry on Every Ride

- How do new dyeing technologies contribute to clean production goals? Transforming Footwear with Sustainable Innovation

- Why is hardware integration and lightweight design emphasized in smart footwear? Key Factors for Mass Production

- Why is the integration of VR and AR headsets a standard in footwear development? Revolutionizing Performance & Comfort