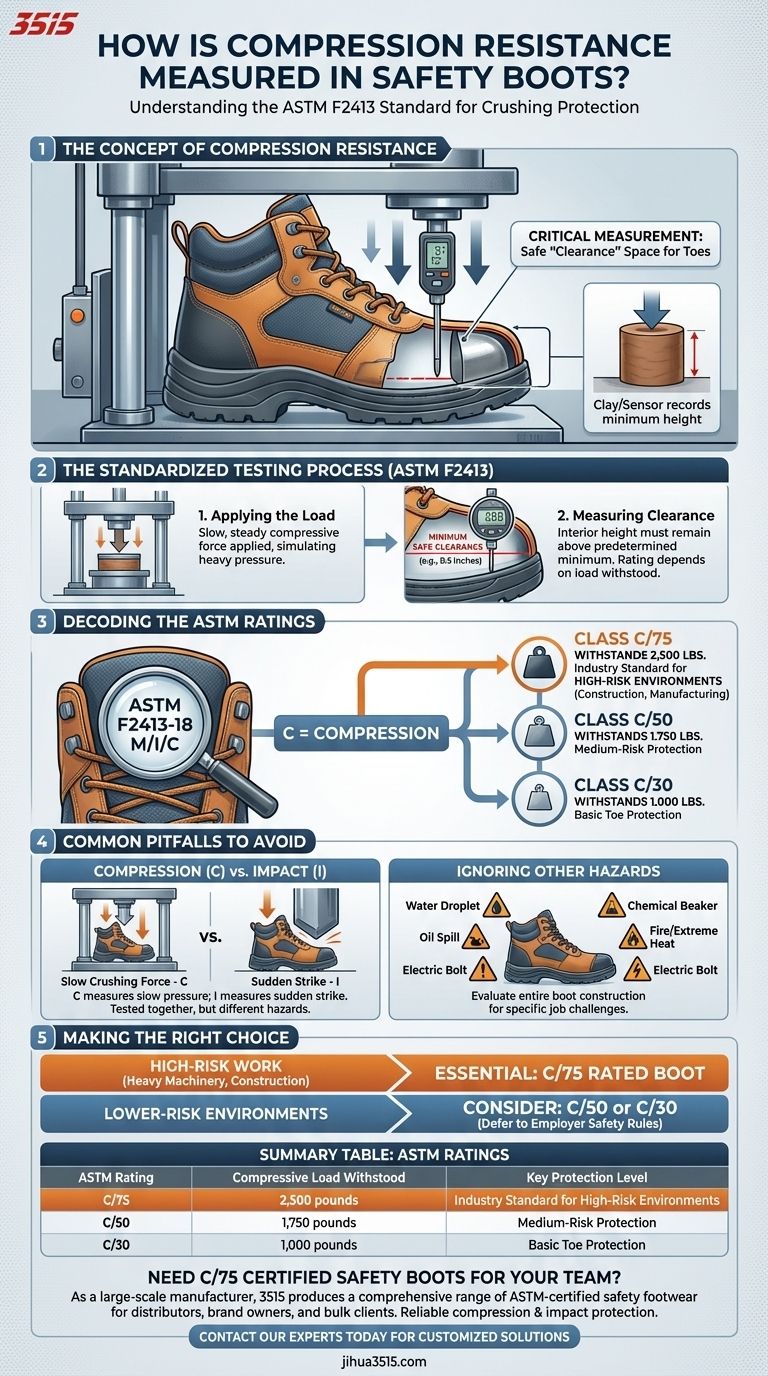

To be precise, compression resistance in safety boots is measured by subjecting the protective toe cap to a significant, slow-moving force and then measuring the amount of space remaining inside. This standardized test, governed by bodies like ASTM International, ensures the boot can protect the wearer's toes from being crushed by a heavy, static load. A boot's rating is determined not just by surviving the force, but by maintaining a minimum safe clearance for the toes.

The critical factor isn't just whether the toe cap withstands the force, but how much safe space—or "clearance"—is left for your toes afterward. The rating you see on a boot's label directly corresponds to this tested level of protection.

The Standardized Testing Process

The method for testing compression resistance is highly controlled to ensure consistent and reliable safety ratings across all certified footwear.

Applying the Compressive Load

Under the common ASTM F2413 standard, the safety toe of the boot is placed in a machine that applies a slow, steady compressive force directly onto it.

This is not a sudden impact test; it simulates the immense pressure of a heavy object slowly rolling onto or pressing down on the foot.

Measuring the Clearance

The key measurement is the interior height remaining inside the toe cap at the moment of maximum compression. A small clay cylinder or digital sensor is often placed inside to record this minimum clearance.

To pass the test for a specific rating, the toe cap must not allow the interior space to be compressed below a predetermined minimum height, which is typically half an inch for men's footwear.

Decoding the ASTM Ratings

The safety rating is typically printed on the tongue of the boot, providing a clear summary of its protective capabilities.

The 'C' Designation

The letter 'C' on an ASTM label specifically stands for Compression. It confirms the boot has been tested and certified for resistance to crushing forces.

Understanding the Class Numbers (30, 50, 75)

Following the 'C', a number indicates the protection class. The highest and most common rating is Class 75.

A C/75 rating signifies that the boot's toe cap can withstand a compressive load of 2,500 pounds while maintaining the minimum required interior clearance.

Lower ratings, such as C/50 and C/30, represent protection against lesser forces and are used for work environments with lower risks.

Why C/75 is the Industry Standard

For most dynamic work environments, such as construction sites, warehouses, and manufacturing floors, the C/75 rating is the recommended standard.

This level of protection is designed to handle the significant risks posed by heavy materials, rolling equipment, and other common workplace hazards.

Common Pitfalls to Avoid

Choosing the right boot requires looking beyond a single number. Understanding the full context of safety features is essential for true on-the-job protection.

Confusing Compression with Impact

Compression ('C') and Impact ('I') are two different tests for two different hazards. A boot with a C/75 rating also has an I/75 rating, which means it protects against a 75-pound object dropped from a specific height.

While they are tested together, one measures slow crushing force (compression), and the other measures a sudden strike (impact).

Ignoring Other Environmental Hazards

A C/75 rating is critical, but it doesn't account for all risks. Your work environment may demand resistance to water, oil, chemicals, or extreme temperatures.

Always evaluate the entire boot construction, including the sole and upper materials, to ensure it matches the specific challenges of your job.

Making the Right Choice for Your Goal

Use the boot's compression rating as a primary guide to match the footwear to the known risks of your environment.

- If your primary focus is working in construction, manufacturing, or with heavy machinery: A C/75 rated boot is the essential and non-negotiable standard for your safety.

- If your primary focus is working in an environment with lower crushing risks but still requiring toe protection: A C/50 or C/30 rating may be sufficient, but always defer to your employer's specific safety requirements.

Understanding what these safety ratings truly measure empowers you to select footwear that provides proven protection for your specific needs.

Summary Table:

| ASTM Rating | Compressive Load Withstood | Key Protection Level |

|---|---|---|

| C/75 | 2,500 pounds | Industry Standard for High-Risk Environments |

| C/50 | 1,750 pounds | Medium-Risk Protection |

| C/30 | 1,000 pounds | Basic Toe Protection |

Need C/75 certified safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure reliable compression resistance and impact protection for workers in construction, manufacturing, and logistics.

Contact our experts today to discuss your safety footwear requirements and receive a customized solution.

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do pressure-sensing insoles achieve load sensing? Optimize Industrial Safety with Real-Time Physical Load Data

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- Why is investing in the right safety shoes important for workplace safety? Protect Your Team and Your Bottom Line

- Why is the maintenance of high-strength metal molds essential? Ensure Superior Safety Shoe Structural Integrity

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- When should damaged work shoes be taken out of service? A Critical Safety Guide

- Why is multi-level supply chain optimization critical for safety shoes? Ensuring Ethics & Performance in Manufacturing

- What role does an industrial-grade plantar pressure platform play in evaluating the performance of protective insoles?