Compliance with EN ISO 20345 is verified through a formal, third-party testing process. A manufacturer must submit a representative model of their safety footwear to an independent, certified organization for rigorous evaluation against the standard's criteria. Upon successful completion of all required tests, the model is issued an Attestation of Type Examination (AET), which serves as its official certificate of compliance and is valid for a period of five years.

The core principle behind EN ISO 20345 certification is independent verification. It is not a self-declaration by the manufacturer, but a formal assurance from an accredited third party that a specific footwear model has met the standard's demanding performance and safety requirements.

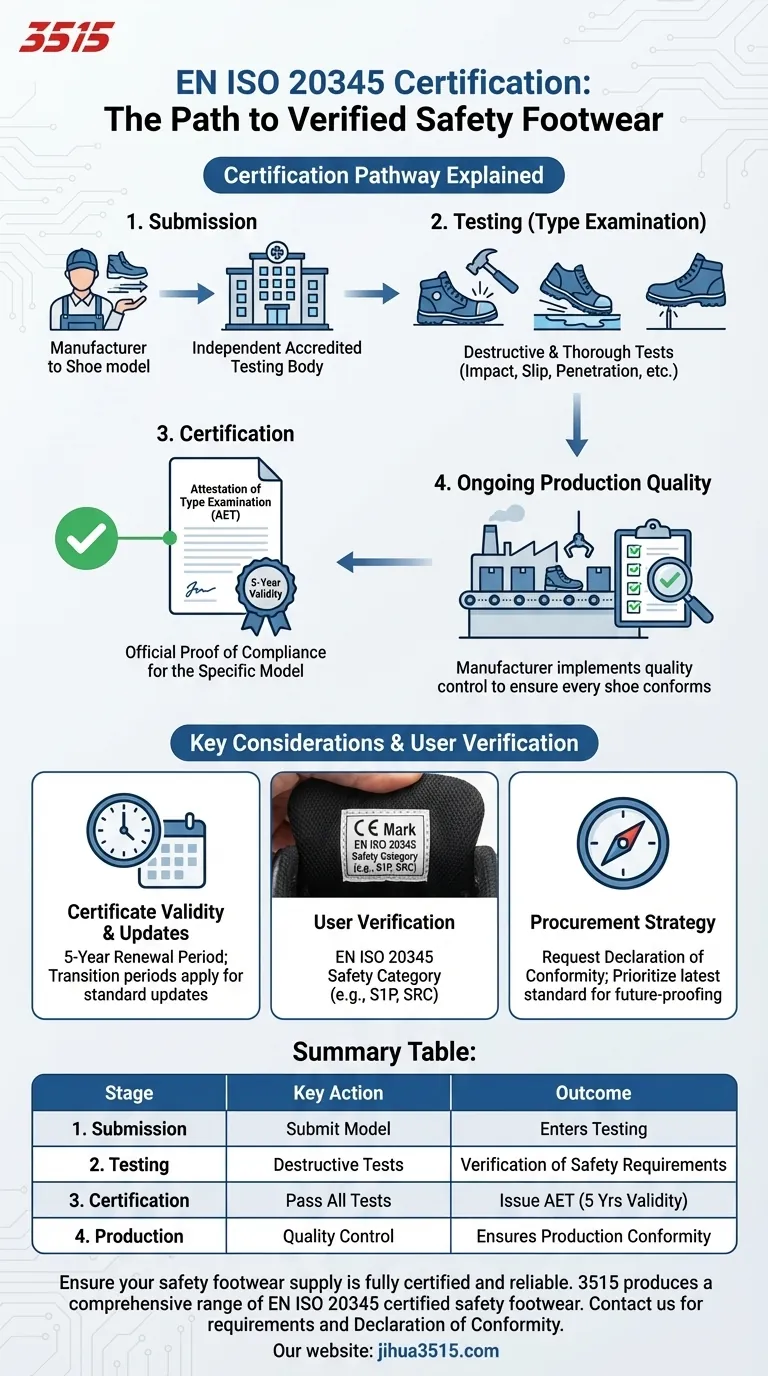

The Certification Pathway Explained

To truly trust the certification, it's important to understand the distinct stages involved. The process is designed to ensure objectivity and consistency from the initial design to the final product a worker wears.

The Role of Certified Organizations

Certification is not performed by a government agency or the manufacturer themselves. It is conducted by independent, accredited testing bodies. These organizations act as impartial referees, equipped with the specialized facilities and expertise to test footwear against the precise specifications of the EN ISO 20345 standard.

The "Type Examination" Process

A manufacturer submits a representative model—the "type"—for examination. This sample undergoes a battery of tests defined by the standard, which may include assessments for:

- Toe cap impact and compression resistance

- Slip resistance on various surfaces

- Penetration resistance of the outsole

- Ergonomic and material quality

This is a destructive and thorough process designed to push the footwear to its limits.

Issuing the Attestation of Type Examination (AET)

If the footwear model passes all required tests, the certified organization issues an Attestation of Type Examination (AET). This is the crucial document that proves compliance. It is specific to that exact model and is valid for a maximum of five years.

Ensuring Ongoing Production Quality

The certification applies to the "type" that was tested. The manufacturer is then responsible for implementing a quality control system to ensure that every shoe coming off the production line continues to conform to the specifications of the originally certified model.

Key Considerations and Common Questions

Understanding the nuances of the certification system is key to making informed decisions, especially when standards are updated.

Certificate Validity and Renewals

The five-year validity period is a critical feature. It ensures that footwear is periodically re-evaluated, which is especially important if the standard itself has been updated or if the manufacturer has made changes to the product's materials or construction.

Handling Standard Updates and Transition Periods

When the EN ISO 20345 standard is updated, a transition period is established. Footwear certified under the previous version of the standard is not immediately obsolete or unsafe. It remains fully compliant and can continue to be sold and used until its original certificate expires. This prevents unnecessary waste and disruption for both suppliers and users.

How to Verify a Shoe's Compliance

For the end-user, verification is straightforward. A compliant safety shoe must be clearly marked, typically on the tongue label. Look for the CE mark (or UKCA mark in the UK), the standard number (EN ISO 20345), and the specific safety category markings (e.g., S1P, S3, SRC).

Making the Right Choice for Your Goal

Use your understanding of the certification process to guide your procurement and safety strategy.

- If your primary focus is ensuring maximum legal compliance: Always request the Declaration of Conformity from your supplier, as this document officially links the product to its certification.

- If your primary focus is managing existing inventory: Recognize that shoes certified to a previous version of the standard are still valid and safe for use throughout the official transition period.

- If your primary focus is future-proofing your procurement: Prioritize sourcing new footwear that is certified to the latest version of the EN ISO 20345 standard.

By understanding this process, you can confidently select footwear that guarantees both proven safety and documented compliance.

Summary Table:

| Certification Stage | Key Action | Outcome |

|---|---|---|

| 1. Submission | Manufacturer submits a representative model to an accredited body. | Footwear enters the formal testing process. |

| 2. Testing | The model undergoes destructive tests (impact, slip, penetration resistance). | Verification of compliance with standard's safety requirements. |

| 3. Certification | Upon passing all tests, an Attestation of Type Examination (AET) is issued. | Official proof of compliance, valid for 5 years. |

| 4. Production | Manufacturer implements a quality control system for ongoing production. | Ensures every shoe matches the certified model's specifications. |

Ensure your safety footwear supply is fully certified and reliable.

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, backed by the necessary documentation for your compliance needs.

Contact us today to discuss your certified footwear requirements and receive a Declaration of Conformity with your order.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection