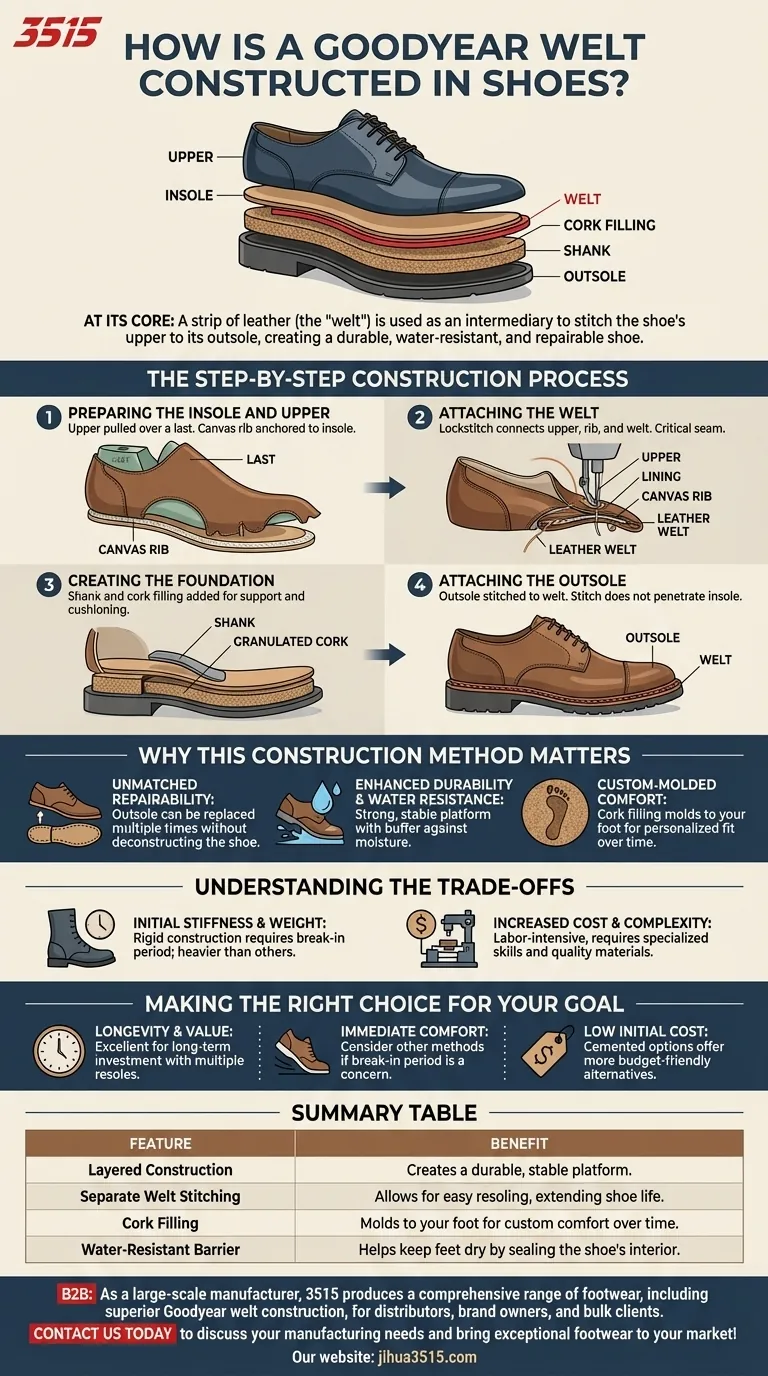

At its core, a Goodyear welt is a shoe construction method where a strip of leather, known as the "welt," is used as an intermediary to stitch the shoe's upper to its outsole. This technique avoids punching stitch holes directly into the insole, creating a more durable, water-resistant, and easily repairable shoe.

The Goodyear welt creates a durable and serviceable shoe by using a separate leather strip to connect the upper and the outsole. This design allows the sole to be replaced multiple times without compromising the shoe's core structure.

The Step-by-Step Construction Process

Understanding the Goodyear welt requires looking at its distinct, layered assembly. Each step contributes to the final product's renowned strength and longevity.

Step 1: Preparing the Insole and Upper

First, the leather upper is pulled tightly over a foot-shaped model called a "last." A canvas rib is then cemented to the bottom edge of the insole. This rib acts as the crucial anchor point for the subsequent stitching.

Step 2: Attaching the Welt

A lockstitch sewing machine then stitches the leather upper, the lining, and the canvas rib to the leather welt that runs along the outside edge of the shoe. This is the most critical seam, forming a secure and stable bond between all upper components.

Step 3: Creating the Foundation

With the welt attached, a void is created between the insole and the outsole's future position. A steel or wooden shank is inserted into this cavity to provide structural support for the arch. The remaining space is then filled, typically with granulated cork, which provides cushioning.

Step 4: Attaching the Outsole

Finally, the outsole is placed onto the shoe and stitched directly to the welt. This final stitch is visible on the top edge of the outsole, running around the perimeter of the shoe. Because this stitch never penetrates the insole, the shoe's interior remains better sealed against moisture.

Why This Construction Method Matters

The multi-step process isn't just for show; it delivers tangible benefits that define high-quality footwear.

Unmatched Repairability

The primary advantage of a Goodyear welt is its repairability. Since the outsole is only stitched to the welt, a cobbler can easily remove the old sole and stitch on a new one without deconstructing the entire shoe. This dramatically extends the footwear's lifespan.

Enhanced Durability and Water Resistance

The interlocking stitches and the welt itself create a very strong, stable platform. The welt also provides a small buffer between the upper and the sole, which helps prevent water from seeping into the shoe from the ground.

Custom-Molded Comfort

The cork filling between the insole and outsole is a key feature. Over time, your body heat and the pressure of your foot compress the cork, creating a custom footbed that molds perfectly to the shape of your arch and gait.

Understanding the Trade-offs

While the Goodyear welt is considered a gold standard, it's important to be aware of its specific characteristics.

Initial Stiffness and Weight

Goodyear welted shoes are inherently more rigid and heavier than their cemented or Blake-stitched counterparts due to their layered construction. They often require a "break-in" period for the stiff leather and cork to soften and conform to your foot.

Increased Cost and Complexity

The process is labor-intensive and requires specialized machinery or highly skilled hand-sewing. This complexity, combined with the quality materials typically used, results in a higher initial purchase price.

Making the Right Choice for Your Goal

Deciding if a Goodyear welted shoe is right for you depends entirely on your priorities.

- If your primary focus is longevity and value over time: The ability to resole the shoe multiple times makes a Goodyear welt an excellent long-term investment.

- If your primary focus is immediate comfort and flexibility: You may prefer a different construction, as the break-in period for a Goodyear welt can be significant.

- If your primary focus is a low initial cost: Less complex construction methods, such as cementing, will offer more budget-friendly options.

Ultimately, choosing a Goodyear welt is an investment in a durable, repairable, and personalized piece of footwear.

Summary Table:

| Feature | Benefit |

|---|---|

| Layered Construction | Creates a durable, stable platform. |

| Separate Welt Stitching | Allows for easy resoling, extending shoe life. |

| Cork Filling | Molds to your foot for custom comfort over time. |

| Water-Resistant Barrier | Helps keep feet dry by sealing the shoe's interior. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the superior Goodyear welt construction. Invest in durable, high-quality footwear that can be resoled for years of service. Contact us today to discuss your manufacturing needs and bring exceptional footwear to your market!

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

People Also Ask

- Why are sneakers now accepted in office environments? The Shift to Modern Professionalism

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style

- What are the key features of high-quality leather in shoes? Invest in Durability and a Perfect Fit

- How does leather compare to other shoe materials in terms of durability and comfort? A Material Guide for Footwear

- Can sneakers be part of a business casual wardrobe? Yes, with the right style and fit