The durability of a classic jungle boot is highly specific to its environment. While exceptionally resilient in their intended wet, muddy conditions, their core design features create vulnerabilities in other terrains. The soles are often the first point of failure on hard surfaces, and historical use in extreme hot, dry conditions has revealed issues with stitching and material dry-rot.

A jungle boot's durability is a function of its specialized design. It is engineered to prioritize drainage and grip in mud over the long-term abrasion resistance needed for modern, varied-terrain use.

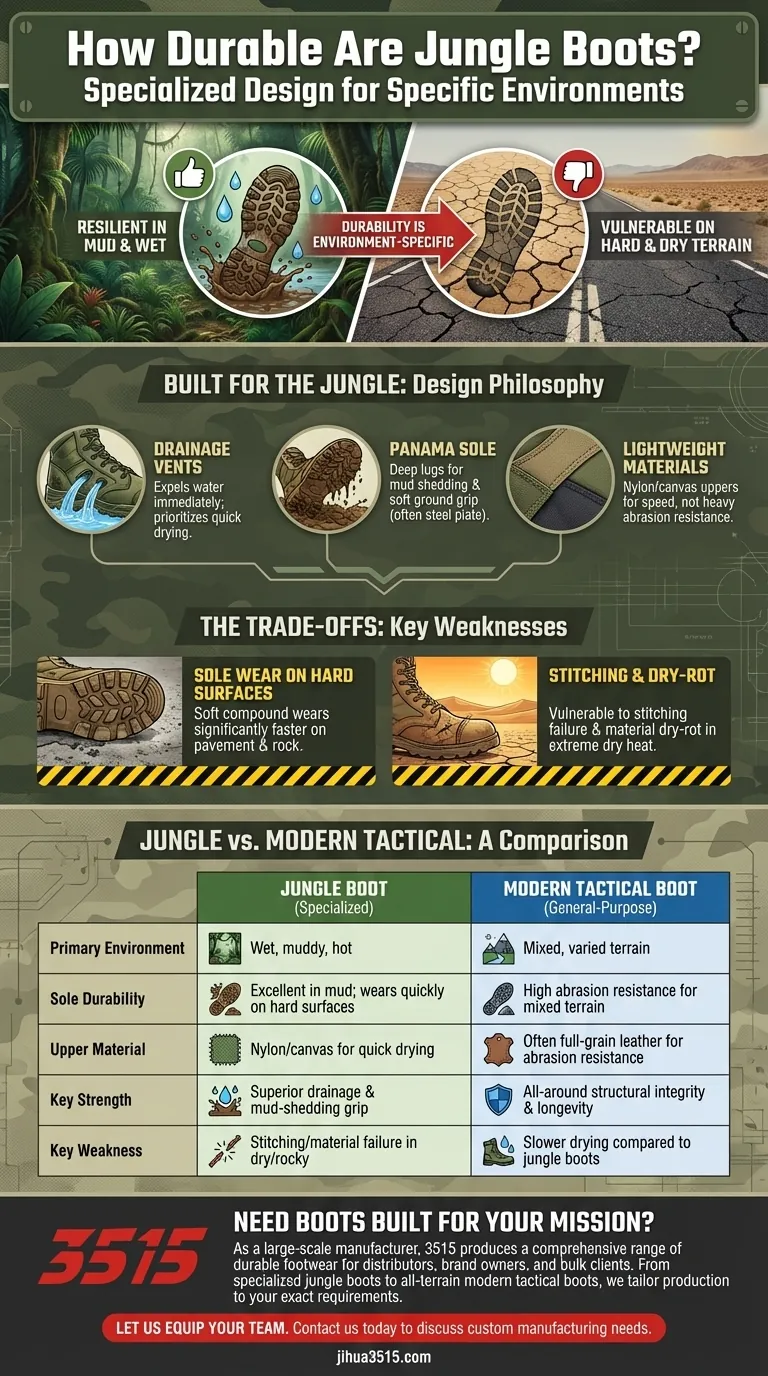

The Design Philosophy: Built for the Jungle

To understand the durability of these boots, you must first understand their original purpose. They were not designed as all-purpose footwear but as a specific tool for a specific job: fighting in a jungle.

Engineered for Water and Mud

Classic jungle boots feature prominent drainage vents near the instep. Their job is to expel water immediately after you've been submerged, allowing the boot and your foot to dry much faster. This design accepts that your feet will get wet and prioritizes quick drying to prevent immersion foot.

The Panama Sole's Purpose

The iconic Panama sole has deep, angled lugs designed to shed mud and provide exceptional grip on soft ground. It often includes a steel plate for protection against ground penetration from spikes or sharp stakes, a critical feature in its original military context.

Lightweight by Design

The uppers are typically made of nylon or canvas, not full-grain leather. This choice keeps the boot lightweight and allows it to dry quickly. However, these materials do not offer the same level of abrasion resistance as modern, heavy-duty leather boots.

Understanding the Trade-offs: Key Weaknesses

The very features that make a jungle boot effective in its element become its primary weaknesses when used as a general-purpose boot.

Sole Wear is the Primary Failure Point

The rubber compound used for the Panama sole is relatively soft to maximize grip in mud. When worn regularly on hard surfaces like pavement or rocky trails, this sole will wear down significantly faster than the sole of a modern hiking or tactical boot.

Stitching and Material Integrity

The construction prioritizes drainage over being perfectly sealed. In extreme conditions outside of the jungle, like the desert, reports from conflicts like the Gulf War noted that the stitching could fail and the materials could suffer from dry-rot, causing the boots to fall apart.

The Modern Tactical Boot Comparison

In contrast, modern tactical boots are built for durability across a wider range of conditions. They typically feature reinforced, heavy-duty stitching and soles made from harder, more wear-resistant compounds designed for mixed terrain. They sacrifice the rapid drainage of a jungle boot for greater overall structural integrity.

Making the Right Choice for Your Needs

Selecting the right boot requires matching its strengths to your intended use.

- If your primary focus is wet, hot, and muddy environments: The classic jungle boot is an excellent, purpose-built tool whose drainage and grip are hard to beat.

- If your primary focus is hiking on rocky or hard-packed trails: A modern tactical or hiking boot with a more durable, reinforced sole will provide a much longer service life.

- If your primary focus is all-around durability for demanding work: Look for a boot with heavy-duty stitching and high-quality leather construction, features more common in modern designs.

Ultimately, choosing the right boot depends on matching its specific design strengths to your mission.

Summary Table:

| Feature | Jungle Boot (Specialized) | Modern Tactical Boot (General-Purpose) |

|---|---|---|

| Primary Environment | Wet, muddy, hot | Mixed, varied terrain |

| Sole Durability | Excellent in mud; wears quickly on hard surfaces | High abrasion resistance for mixed terrain |

| Upper Material | Nylon/canvas for quick drying | Often full-grain leather for abrasion resistance |

| Key Strength | Superior drainage & mud-shedding grip | All-around structural integrity & longevity |

| Key Weakness | Stitching/material failure in dry/rocky conditions | Slower drying compared to jungle boots |

Need Boots Built for Your Specific Mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Whether you need the specialized performance of a jungle boot or the all-terrain durability of a modern tactical boot, our production capabilities encompass all types of shoes and boots tailored to your exact requirements.

Let us help you equip your team with the right footwear for the job.

Contact us today to discuss your custom manufacturing needs.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What technical requirements are essential for outsoles in pivoting sports? Boost Grip and Lateral Stability

- What are some alternatives to hunting boots? Hiking, Rubber & Tactical Boots Explained

- Why are vulcanized soles popular in urban fashion? Discover the Legacy of Authentic Street Style

- How do hiking shoes or boots protect feet from environmental hazards? A Guide to Trail-Ready Footwear