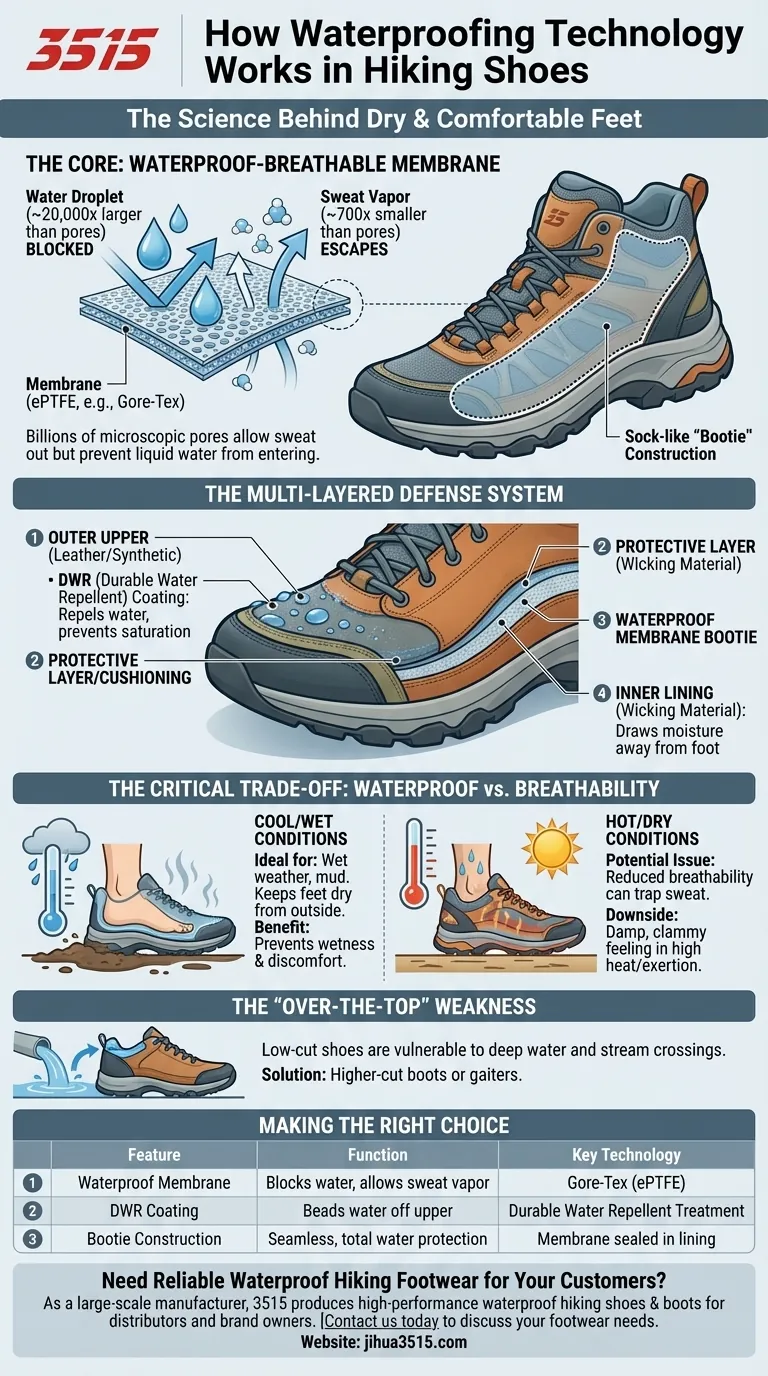

At its core, waterproofing in hiking shoes works by using a specialized internal layer called a membrane. This membrane, most famously Gore-Tex, is engineered with microscopic pores large enough to let water vapor (sweat) out, but too small for liquid water droplets to get in. This waterproof-breathable membrane is constructed into a sock-like "bootie" that is sandwiched between the shoe's inner lining and outer materials.

The essential principle of waterproof footwear is not just about blocking external water, but managing a fundamental trade-off. The technology creates a barrier against rain and puddles at the inevitable cost of reduced breathability, which directly impacts foot comfort in different climates.

The Multi-Layered Defense System

Modern waterproof hiking shoes don't rely on a single feature. Instead, they employ a sophisticated system of layers, each with a distinct role in keeping your feet dry from both external and internal moisture.

The Core Component: The Waterproof Membrane

The heart of the system is the waterproof-breathable membrane. This is typically a thin film of expanded polytetrafluoroethylene (ePTFE), the material used in Gore-Tex.

Its genius lies in its microscopic structure, which contains billions of pores per square inch. These pores are about 20,000 times smaller than a water droplet, making it impossible for rain or puddle water to penetrate.

Crucially, these same pores are about 700 times larger than a water vapor molecule. This allows perspiration from your foot to escape, a process often referred to as "breathability."

The "Bootie" Construction

This membrane is not just laid flat inside the shoe. It is shaped, seamed, and sealed into a complete, sock-like bootie.

This bootie is then placed between a comfortable inner lining (which wicks moisture away from your foot) and the shoe's visible outer structure, often with foam for cushioning. This seamless construction ensures there are no gaps for water to seep through.

The First Line of Defense: The Upper

The shoe's exterior material, or upper, provides the initial barrier. While the internal bootie does the heavy lifting, the upper is designed to repel as much water as possible on its own.

Uppers made of leather or synthetic fabrics are often treated with a Durable Water Repellent (DWR) coating. This chemical treatment causes water to bead up and roll off the surface, preventing the outer fabric from becoming saturated and heavy.

Understanding the Critical Trade-off

No technology is without its limitations. The decision to choose a waterproof shoe involves navigating a critical compromise between keeping external water out and letting internal moisture escape.

Why "Waterproof" Doesn't Mean "Sweat-Proof"

While the membrane is designed to be breathable, it can never match the airflow of a non-waterproof shoe with open mesh panels. Sealing the shoe to block water inherently restricts the escape route for sweat.

In warm or high-exertion conditions, your foot may produce sweat faster than it can pass through the membrane. This can lead to a damp, clammy feeling inside the shoe, even though no external water has entered.

The Impact of Climate and Conditions

This trade-off makes shoe selection highly dependent on your environment.

In cool, wet, or muddy conditions, a waterproof shoe is invaluable. It keeps your feet dry and comfortable, preventing blisters and discomfort associated with wet socks.

In hot, dry climates, that same waterproof shoe can become a liability. The reduced breathability traps heat and sweat, potentially leading to more discomfort than a non-waterproof shoe that gets wet but dries quickly.

The "Over-the-Top" Weakness

A waterproof membrane is useless if water can simply pour in over the collar of your shoe. This is a common issue with low-cut waterproof hiking shoes.

While they can protect you from shallow puddles or light rain, stepping into a stream or a deep puddle will flood the shoe from the ankle opening, trapping the water inside.

Making the Right Choice for Your Hikes

Understanding this technology allows you to select the right tool for the job. Your choice should be dictated by the conditions you expect to face most often.

- If your primary focus is hiking in wet, cool, or unpredictable weather: A waterproof shoe with a membrane is the superior choice for reliable protection.

- If your primary focus is hiking in consistently hot and dry climates: A non-waterproof, highly ventilated shoe will provide far better comfort by maximizing sweat evaporation.

- If your primary focus is crossing deep streams or hiking in constant downpours: Pair a higher-cut waterproof boot with gaiters to prevent water from entering over the top.

Ultimately, choosing the right hiking shoe is about matching the technology's strengths and weaknesses to your specific adventure.

Summary Table:

| Feature | Function | Key Technology |

|---|---|---|

| Waterproof Membrane | Blocks external water, allows sweat vapor to escape | Gore-Tex (ePTFE) with microscopic pores |

| DWR Coating | Causes water to bead up and roll off the upper | Durable Water Repellent chemical treatment |

| Bootie Construction | Seamless, sock-like layer for total water protection | Membrane sealed between inner lining and outer materials |

Need Reliable Waterproof Hiking Footwear for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance waterproof hiking shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable construction, advanced membrane technology, and consistent quality for your market.

Contact us today to discuss your footwear needs and explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why is proper fit critical for hiking boots? Ensure Comfort, Stability & Injury Prevention

- Why is technical attribute modeling of professional climbing footwear necessary? Ensure Peak Mountaineering Safety

- Why is a secure lacing system important in hiking boots? Prevent Blisters & Boost Stability

- What is the difference between a hiking boot and a hiking shoe? Find Your Perfect Trail Footwear

- Why is crampon compatibility important for hiking boots? Ensure Your Boots & Crampons Work as One

- What are speed hooks, and how do they function? Get Your Boots On & Off Faster

- What are the four main types of hiking shoes? Find Your Perfect Trail Match

- What are the key factors to consider when choosing hiking boots for temperate climates?