To properly apply waterproof spray, the process involves thoroughly cleaning the material, applying one or two thin, even coats in a well-ventilated area, and allowing the item to dry completely between coats and before use. This application creates an invisible, protective barrier that repels moisture.

The effectiveness of a waterproof spray isn't just in the product itself, but in the methodical process. True water resistance is achieved through a cycle of three key steps: diligent preparation, correct application, and consistent maintenance.

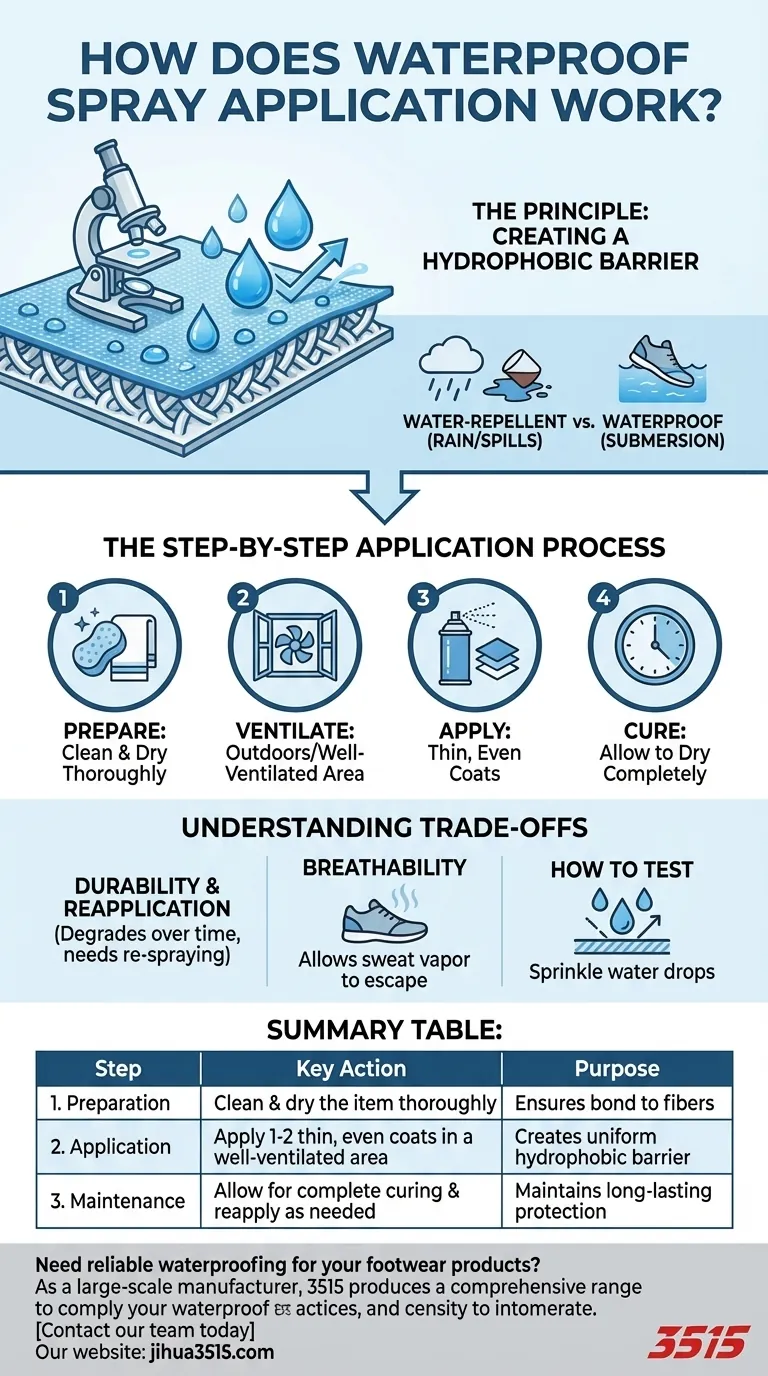

The Principle: Creating a Hydrophobic Barrier

At its core, a waterproof spray works by coating the fibers of a material with a protective, water-repellent layer.

How the Barrier Functions

Waterproof sprays contain polymers or fluoropolymers that, when cured, create a surface with extremely low surface energy. This forces water to form beads with a high contact angle, causing it to roll off rather than soak into the fabric.

This microscopic barrier is what provides protection against water, dirt, and stains without changing the look or feel of the material.

Water-Repellent vs. Waterproof

It is critical to understand that these sprays make an item water-repellent or water-resistant, not truly waterproof. They are designed to protect against rain and spills, but they will not make a pair of canvas shoes suitable for full submersion in water.

The Step-by-Step Application Process

A hasty application will yield poor results. Following a systematic process ensures the protective barrier forms correctly and lasts as long as possible.

Step 1: Thoroughly Prepare the Surface

The spray must bond directly to the material's fibers. Start by cleaning the item to remove all dirt, dust, and grime. A barrier applied over dirt is a barrier that will quickly fail.

Ensure the item is completely dry before you begin spraying.

Step 2: Ensure Proper Ventilation

These sprays release fumes that should not be inhaled. Always apply the product outdoors or in a very well-ventilated space like an open garage.

Step 3: Apply Thin, Even Coats

Holding the can at the distance recommended by the manufacturer, apply a light, even coat using a sweeping motion. Do not saturate the material.

It is far more effective to apply two thin coats than one thick, heavy coat. Pay special attention to vulnerable areas like seams.

Step 4: Allow for Complete Curing

Patience is key. Let the first coat dry completely before applying a second one. After the final coat, allow the item to cure for the time specified in the instructions before exposing it to moisture.

Avoid using direct heat sources like hair dryers to speed up the process, as this can damage the material or the protective barrier.

Understanding the Trade-offs

Waterproof sprays are convenient and effective, but it's important to recognize their limitations to set realistic expectations.

Durability and Reapplication

The protective barrier created by a spray is not permanent. It degrades over time due to friction, abrasion, and cleaning.

For items worn daily or exposed to heavy rain, expect to reapply the treatment every few weeks to maintain protection.

Breathability is the Key Advantage

One of the primary benefits of a spray treatment is that it maintains the material's original breathability. This is crucial for footwear and outerwear, as it allows sweat vapor to escape, keeping you dry from the inside.

How to Test for Effectiveness

You can easily check if the barrier is still working. Sprinkle a few drops of water on the surface. If the water beads up and rolls off, the protection is intact. If it starts to darken the material and soak in, it is time to reapply.

Making the Right Choice for Your Goal

Use this guidance to determine how to best apply these principles to your specific needs.

- If your primary focus is protecting delicate materials like suede or nubuck: A spray is the ideal choice, as it will not compromise the texture or breathability.

- If your primary focus is convenience for everyday items: Sprays provide the quickest and easiest method for maintaining a baseline of water resistance on shoes, bags, and jackets.

- If your primary focus is maximum durability for heavy-use gear: A spray is an excellent starting point, but consider it part of a system that may require reapplication more frequently after heavy exposure.

By following a deliberate process of preparing, applying, and maintaining the protective barrier, you can reliably extend the life and performance of your gear.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Clean & dry the item thoroughly | Ensures the spray bonds directly to the material fibers |

| 2. Application | Apply 1-2 thin, even coats in a well-ventilated area | Creates a uniform, effective hydrophobic barrier |

| 3. Maintenance | Allow for complete curing and reapply as needed | Maintains long-lasting protection and performance |

Need reliable waterproofing for your footwear products? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can provide expert guidance on finishing treatments like waterproofing to ensure your products meet market demands for quality and durability. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What materials are recommended for shoe linings to improve comfort? Choose Breathable Mesh for All-Day Wear

- Why are boots considered a must-have in every man's wardrobe? Unlock Style, Durability & Versatility

- Why are flexible resistive array pressure sensors utilized to evaluate the impact of work fatigue on foot kinetics? Enhance Biomechanical Accuracy

- What is the second method for choosing shoelace length? A Simple Guide Using Eyelet Count

- How does the static optimization process in biomechanical models assist in the estimation of muscle forces?

- What is the benefit of using a multi-functional training station for CRT? Maximize Efficiency & Metabolic Health

- What is the historical origin of cowboy boots? Discover the Design Built for the Saddle

- What role does an Ultra-Wideband (UWB) wireless ranging module play in decentralized cooperative positioning? Boost Accuracy