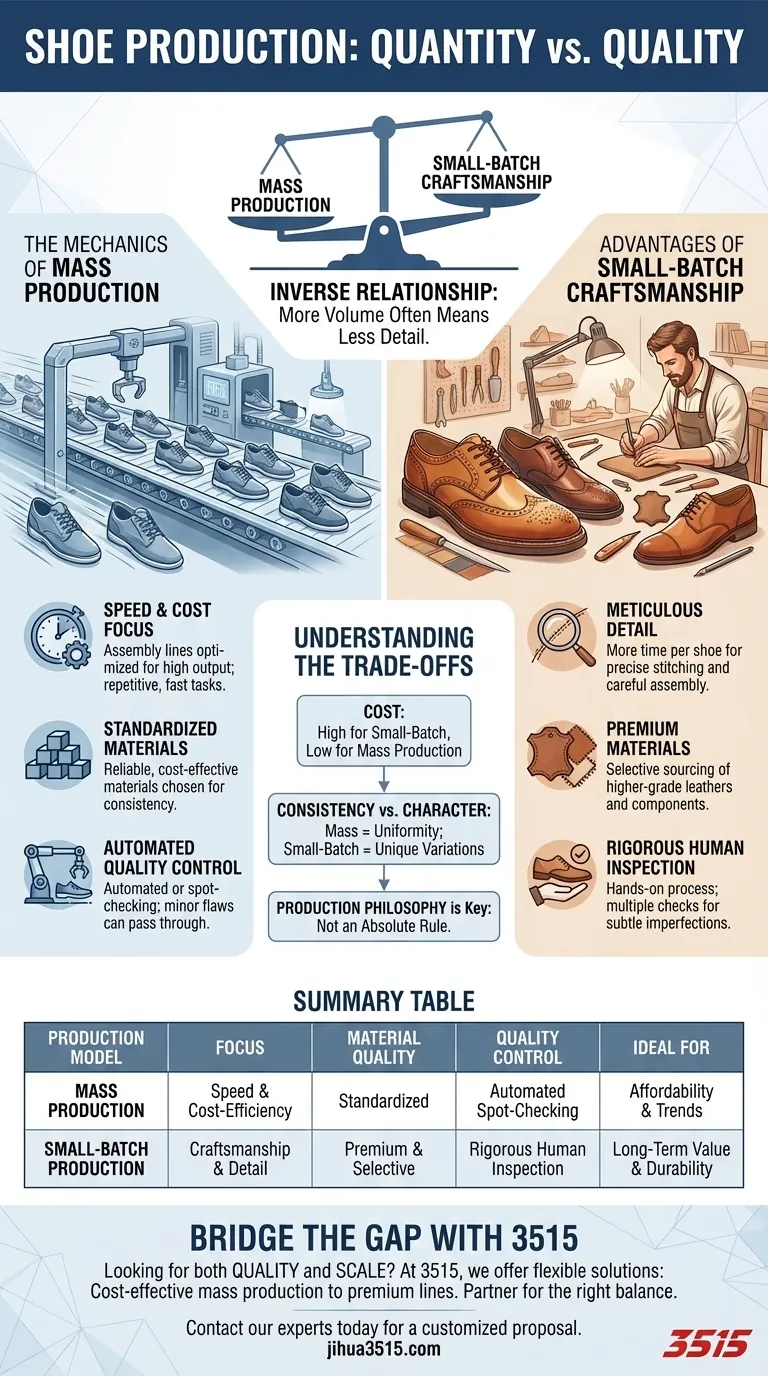

In short, yes. There is often an inverse relationship between the production quantity of shoes and their final quality. Mass production prioritizes speed and cost-efficiency, which can lead to compromises in craftsmanship and materials, while smaller production batches allow for greater attention to detail and superior construction.

The core issue isn't the number of shoes produced, but the manufacturing philosophy that number represents. Mass production is engineered for cost and scale, whereas small-batch production is structured to allow for craftsmanship and meticulous quality control.

The Mechanics of Mass Production

The goal of mass production is to create a consistent product at the lowest possible cost per unit. This philosophy directly influences every stage of the manufacturing process and can impact the final quality.

The Focus on Speed

In a mass-production environment, assembly lines are optimized for output. Each worker performs a single, repetitive task at high speed, leaving little room for nuanced adjustments or detailed finishing.

Material Standardization

To ensure consistency and control costs across millions of units, large-scale manufacturers rely on standardized materials. These materials are chosen for their reliability and cost-effectiveness, but they may not be the highest-grade or most durable options available.

Automated Quality Control

While large brands have quality control, it is often automated or based on spot-checking. With thousands of shoes produced daily, it's not feasible to inspect every single stitch on every shoe, meaning minor flaws can more easily pass through.

The Advantages of Small-Batch Craftsmanship

Small-batch or artisanal shoemaking operates on a different set of principles. The focus shifts from sheer volume to the quality of the individual product.

Meticulous Attention to Detail

When producing fewer pairs, craftspeople can dedicate more time to each shoe. This allows for more precise stitching, careful assembly of components, and a higher-quality finish that is difficult to replicate on a fast-moving assembly line.

Selection of Premium Materials

Smaller producers are not bound by the same supply chain constraints as global brands. They can be more selective, often sourcing higher-grade leathers, textiles, and components that are not available or are too costly for mass production.

Rigorous Human Inspection

In a small-batch setting, quality control is a hands-on process. Each shoe is typically inspected multiple times by a skilled individual who can identify and correct subtle imperfections that an automated system would miss.

Understanding the Trade-offs

The relationship between quantity and quality is a strong correlation, but it's important to recognize the associated trade-offs and exceptions.

The Inevitable Cost Factor

The primary trade-off is price. The intensive labor, superior materials, and detailed quality control of small-batch shoes result in a significantly higher cost. Mass-produced shoes are, by design, more accessible and affordable.

Consistency vs. Character

Mass production delivers remarkable consistency—the thousandth shoe looks exactly like the first. Hand-finished shoes from smaller batches may have slight, unique variations, which connoisseurs often value as "character."

It's Not an Absolute Rule

Some large, reputable brands have invested heavily in high-end production lines and maintain excellent quality control. Conversely, a small brand does not automatically guarantee high quality. The production philosophy is the key indicator.

Making the Right Choice for Your Goal

Your ideal shoe depends on what you value most. Use the production model as a guide to find what aligns with your needs.

- If your primary focus is long-term value and durability: Seek out brands known for smaller production runs, as their attention to detail and material quality often translates to a longer lifespan.

- If your primary focus is affordability and current trends: Mass-produced shoes offer a cost-effective way to access fashionable styles for a season, but manage your expectations for their longevity.

- If your primary focus is a balance of quality and accessibility: Research established brands that have specific, premium product lines where they invest more in craftsmanship and materials.

Ultimately, understanding the philosophy behind how a shoe is made empowers you to look past the label and choose for genuine quality.

Summary Table:

| Production Model | Focus | Material Quality | Quality Control | Ideal For |

|---|---|---|---|---|

| Mass Production | Speed & Cost-Efficiency | Standardized | Automated Spot-Checking | Affordability & Trends |

| Small-Batch Production | Craftsmanship & Detail | Premium & Selective | Rigorous Human Inspection | Long-Term Value & Durability |

Looking for a manufacturer that delivers both quality and scale?

At 3515, we bridge the gap. As a large-scale manufacturer, we produce a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to offer flexible solutions from cost-effective mass production to premium lines with enhanced craftsmanship and material selection.

Partner with us to get the right balance of quality, price, and volume for your market.

Contact our experts today to discuss your specific needs and receive a customized proposal.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Leather Business Casual Shoes with Dial Closure - Manufacturer of Comfort Dress Sneakers

- Wholesale Comfort Dress Shoes with Dial Closure for Custom Manufacturing

- Wholesale Perforated Comfort Dress Shoes | Custom Derby Shoe Manufacturer

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

People Also Ask

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- Is it acceptable to wear dress shoes with casual outfits? Elevate Your Smart Casual Office Style

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear