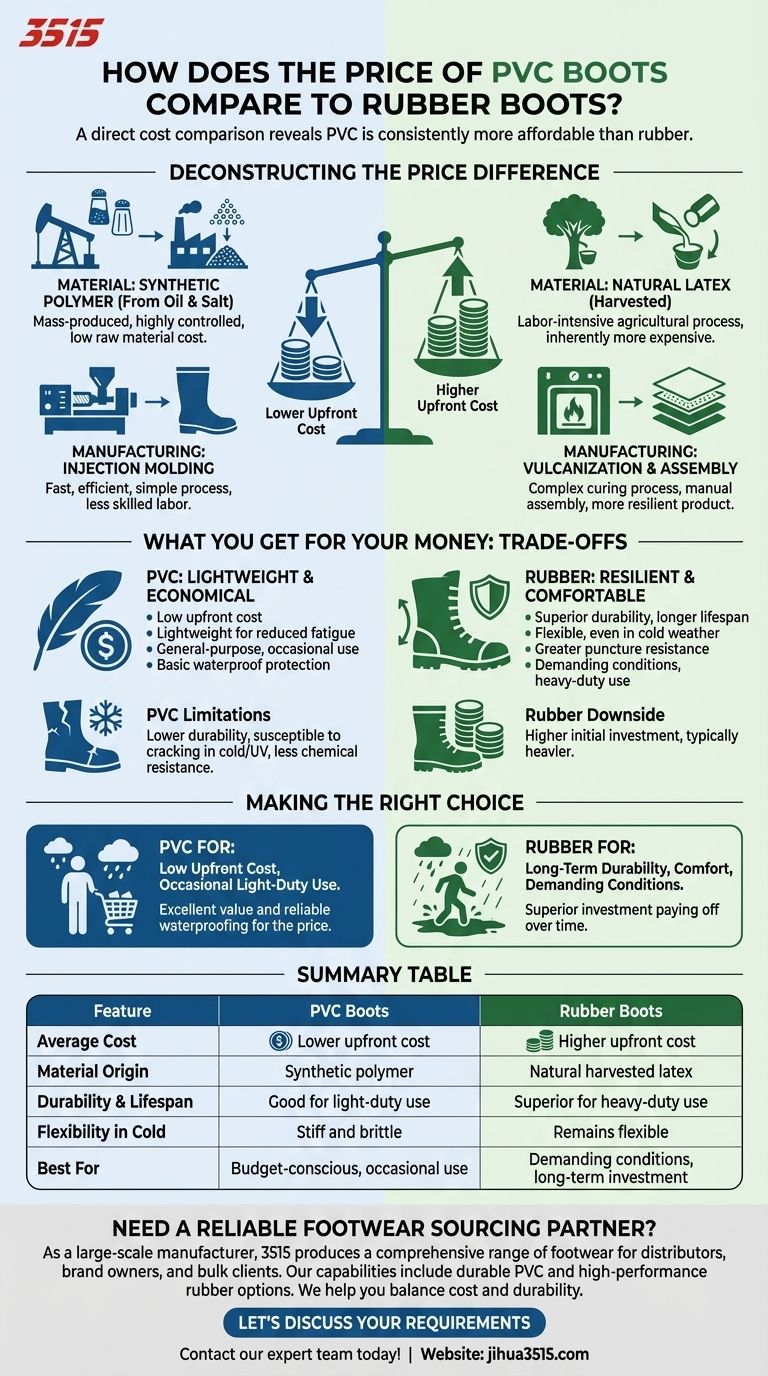

On a direct cost comparison, PVC boots are consistently more affordable than rubber boots. This price difference is rooted in the core materials themselves. PVC is an inexpensive, mass-produced synthetic plastic, while natural rubber is a harvested material that is more costly to source and process.

The choice between PVC and rubber boots is a classic trade-off between upfront cost and long-term performance. PVC provides an immediate, budget-friendly waterproof solution, while rubber commands a higher price for its superior durability, flexibility, and comfort.

Deconstructing the Price Difference

To understand the cost disparity, you must look at how each material is produced and what that means for the final product.

The Cost of Materials: Synthetic vs. Natural

PVC (Polyvinyl Chloride) is a synthetic polymer derived from salt and oil. Its production is a highly controlled, large-scale industrial process, which keeps the raw material costs low.

Natural rubber, by contrast, is harvested as latex from rubber trees. This is a more labor-intensive, agricultural process, making the raw material inherently more expensive than a synthetic plastic.

Manufacturing and Durability

PVC boots are typically made using a simple injection-molding process, which is fast, efficient, and requires less skilled labor, further reducing production costs.

Rubber boots often require a more complex process called vulcanization to cure the rubber, along with manual assembly of different components. This adds time and cost but results in a more resilient and durable final product.

What You Get for Your Money

The price difference reflects a clear distinction in performance and intended use. Each material offers a unique set of benefits.

The Case for PVC: Lightweight and Economical

PVC's primary advantages are its low cost and light weight. This makes PVC boots an excellent choice for general-purpose tasks or jobs that require frequent walking and basic waterproof protection without exposure to harsh chemicals or extreme temperatures.

The Case for Rubber: Resilient and Comfortable

Rubber boots justify their higher price with superior performance. They offer better flexibility, especially in cold weather where PVC can become stiff and brittle. They also provide greater puncture resistance and a longer overall lifespan under heavy use.

Understanding the Trade-offs

Neither boot is universally better; the right choice depends entirely on your specific requirements and environment.

PVC's Limitations

The main drawback of PVC is its lower durability compared to rubber. It is more susceptible to cracking over time, especially with frequent flexing or exposure to UV light and extreme cold. It also offers less resistance to chemicals and abrasion.

Rubber's Downside: Cost and Weight

The most significant barrier to choosing rubber is the higher initial investment. Additionally, rubber boots are typically heavier than their PVC counterparts, which can be a consideration for those who value minimizing fatigue over long periods.

Making the Right Choice for Your Needs

Base your decision on the demands of your environment and your budget priorities.

- If your primary focus is a low upfront cost for occasional or light-duty use: PVC boots offer excellent value and reliable waterproofing for the price.

- If your primary focus is long-term durability, comfort, and performance in demanding conditions: Investing in rubber boots is the superior choice that will pay off over time.

Ultimately, understanding these material differences allows you to select the right tool for the job, balancing immediate cost against your long-term requirements.

Summary Table:

| Feature | PVC Boots | Rubber Boots |

|---|---|---|

| Average Cost | Lower upfront cost | Higher upfront cost |

| Material Origin | Synthetic polymer (from oil/salt) | Natural harvested latex |

| Durability & Lifespan | Good for light-duty use | Superior for heavy-duty use |

| Flexibility in Cold | Can become stiff and brittle | Remains flexible |

| Best For | Budget-conscious buyers, occasional use | Demanding conditions, long-term investment |

Need a Reliable Partner for Your Footwear Sourcing?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable PVC and high-performance rubber options. We help you navigate material choices to find the perfect balance of cost and durability for your market.

Let's discuss your specific requirements and get a competitive quote.

Contact our expert team today to start your order!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- How does the fiber entanglement process contribute to material efficiency? Shift to Zero-Waste Footwear Production

- What are the key features of winter cycling shoes designed to keep feet warm? Essential Gear for Cold Weather Rides

- What are the advantages of integrating sensors into footwear for gait assistance? Precision & User Compliance

- What should consumers look for to avoid misleading claims about leather quality? A Guide to Identifying Genuine Quality

- Why is a 50kN UTM with a high-precision load cell required for assessing footwear leather adhesives? Ensure Bond Durability

- Why is Electrospinning technology considered irreplaceable in the preparation of high-end protective smart textiles for specialized footwear?

- How do shoe sizes differ between men and women? A Guide to Finding the Perfect Fit

- What is a Goodyear shoe? A Guide to Durable, Resolable Footwear Craftsmanship