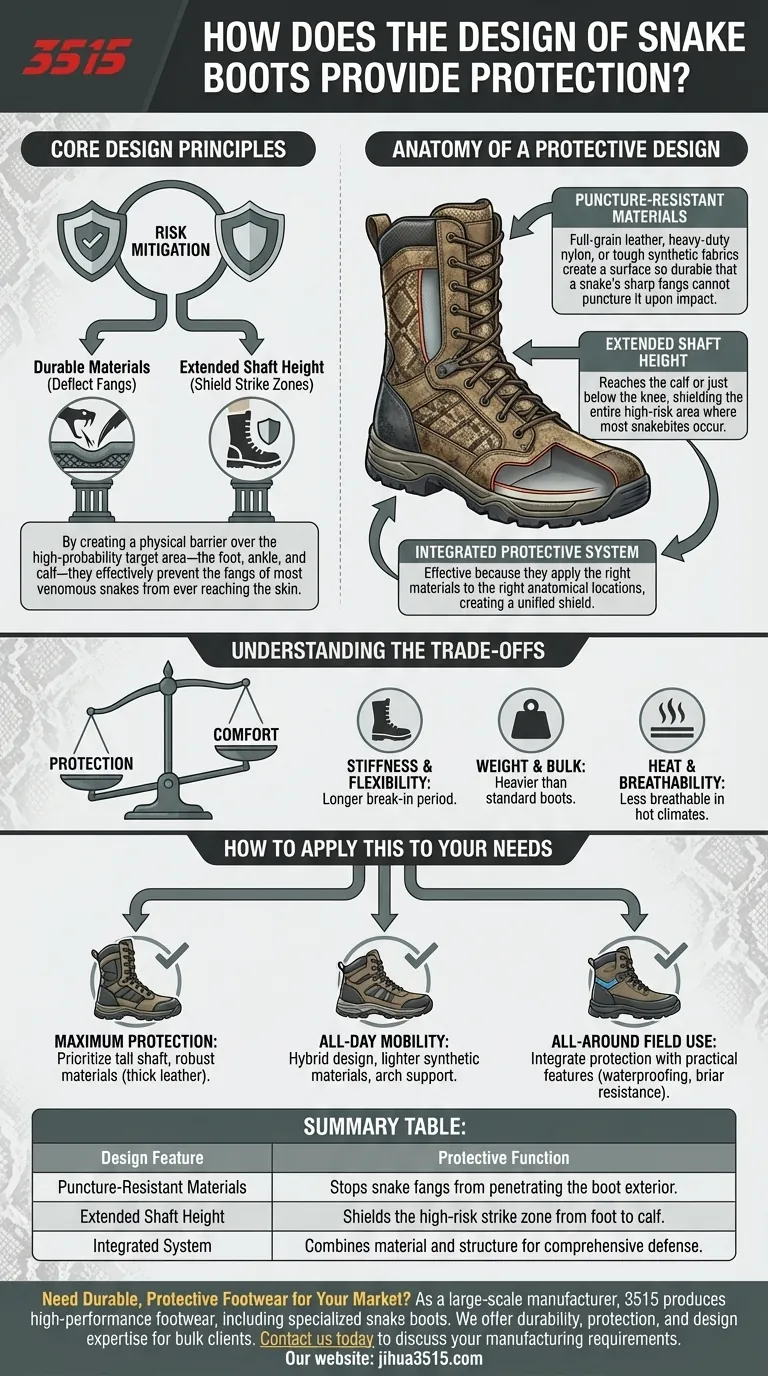

Snake boot protection is a function of two core design principles. They work by combining exceptionally durable, puncture-resistant materials with an extended shaft height that shields the vulnerable lower leg. This integrated system is engineered to both deflect a snake's fangs and cover the most common strike zones on the human body.

The central strategy behind snake boot design is risk mitigation. By creating a physical barrier over the high-probability target area—the foot, ankle, and calf—they effectively prevent the fangs of most venomous snakes from ever reaching the skin.

The Anatomy of a Protective Design

To understand how snake boots work, it's essential to look at how their components function together as a system. The effectiveness does not come from a single feature, but from the combination of material and structure.

Material Selection: The First Line of Defense

The exterior of a snake boot is its armor. Manufacturers use materials specifically chosen for their high density and resistance to penetration.

This often includes full-grain leather, heavy-duty nylon, or other tough synthetic fabrics. The goal is to create a surface so durable that a snake's sharp, needle-like fangs cannot puncture it upon impact.

Extended Shaft Height: Shielding the Strike Zone

The most critical design element is the boot's height. The shaft extends far beyond the ankle, typically reaching the calf or just below the knee.

This is a direct response to snake behavior. The vast majority of venomous snakebites occur on the lower extremities. By providing comprehensive coverage from the foot to the calf, the boots shield this entire high-risk area.

An Integrated Protective System

Neither material nor height is sufficient on its own. A tall boot made of weak material would offer no real protection, and a puncture-proof shoe would leave the ankle and calf completely exposed.

Snake boots are effective because they apply the right materials to the right anatomical locations, creating a unified shield where it is most needed.

Understanding the Trade-offs

While highly effective, the design features necessary for snake protection introduce certain trade-offs compared to standard footwear.

Stiffness and Flexibility

The dense materials required to stop fangs are inherently stiffer than those used in typical hiking or work boots. This can mean a longer break-in period is required to achieve comfortable flexibility.

Weight and Bulk

Adding durable layers and extending the boot's height naturally adds weight and bulk. While many modern designs are impressively lightweight, they will almost always be heavier than a standard boot of the same size.

Heat and Breathability

Materials dense enough to be puncture-proof are often less breathable. In hot and humid climates, this can lead to more heat and moisture retention compared to more ventilated footwear.

How to Apply This to Your Needs

Choosing the right boot involves matching its protective features to your specific environment and activity level.

- If your primary focus is maximum protection: Prioritize boots with the tallest shaft and the most robust materials, such as thick leather or multiple layers of synthetic weaves.

- If your primary focus is all-day mobility: Look for a hybrid design that uses lighter synthetic materials and emphasizes features like arch support, accepting a balance between weight and absolute toughness.

- If your primary focus is all-around field use: Consider boots that integrate protection with practical features like waterproofing and briar resistance for versatile performance.

Ultimately, selecting the right snake boot is about making an informed decision that aligns its protective engineering with the realities of your environment.

Summary Table:

| Design Feature | Protective Function |

|---|---|

| Puncture-Resistant Materials | Stops snake fangs from penetrating the boot exterior. |

| Extended Shaft Height | Shields the high-risk strike zone from foot to calf. |

| Integrated System | Combines material and structure for comprehensive defense. |

Need Durable, Protective Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear, including specialized snake boots. We offer the durability, protection, and design expertise that distributors, brand owners, and bulk clients require. Our production capabilities encompass all types of shoes and boots, ensuring you get the right product for your customers' needs.

Contact us today to discuss your manufacturing requirements and learn how we can bring value to your supply chain.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How are winter boot insulation ratings measured? A Guide to Warmth, Activity, and Fit

- How should hunting boots be stored during the off-season? Maximize Lifespan with Proper Care

- Is analyzing foot pronation or supination necessary when choosing walking shoes? Prioritize Comfort and Fit Instead

- What are the benefits of lightweight hunting boots? Maximize Mobility & Reduce Fatigue

- Why are counters sewn differently in cowboy boots? For Unmatched Strength in the Stirrup

- How often should tall boots be conditioned and polished? A Responsive Guide to Leather Care

- What are snake boots designed for? Ultimate Protection Against Snakebites & Outdoor Hazards

- What role does footwear with high support performance play in preventing falls in the elderly? Engineering Stability