In footwear production, side leather's primary distinction is its exceptional versatility, stemming from how it is processed. It refers to a cattle hide that has been split down the backbone into two large, manageable "sides," which then serve as a robust canvas for a vast array of finishes and textures.

Side leather is defined by its cut, not a specific finish. This makes it a foundational material that can be transformed to mimic other leathers or create unique styles, setting it apart from leathers like nubuck, which are defined by their specific surface treatment.

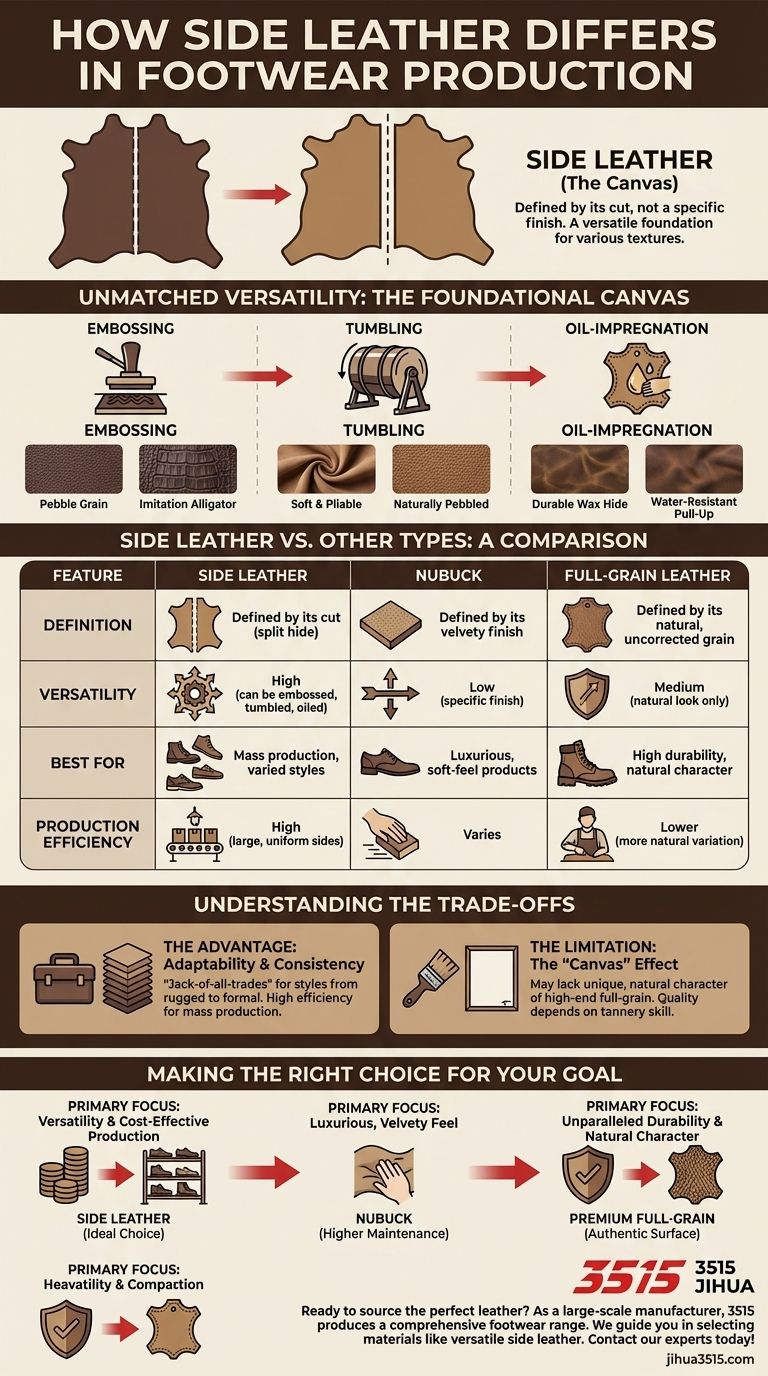

What Truly Defines Side Leather?

Side leather's identity is rooted in its origin as a large, practical portion of a hide. This starting point is what enables its widespread use and adaptability in the footwear industry.

The Cut: A Foundation for Manufacturing

A full cattle hide is large and difficult to handle. By splitting it down the middle, tanneries create two "sides" that are more uniform in thickness and easier for manufacturers to cut patterns from efficiently. This process maximizes yield and minimizes waste.

The Canvas: Unmatched Versatility

Once cut, a side of leather can undergo numerous finishing processes. This adaptability is its core strength.

- Embossing: Presses can stamp the surface with artificial grain patterns, such as pebble grain or even an imitation alligator texture.

- Tumbling: The leather can be tumbled in a large drum to soften the fibers, creating a more supple and pliable material with a naturally pebbled texture.

- Oil-Impregnation: The leather is treated with oils and waxes to create a durable, often water-resistant "wax hide" or pull-up leather that develops a unique patina over time.

How Side Leather Compares to Other Types

Understanding side leather requires comparing it to other common materials used in footwear, which are often defined by their finish or the part of the hide they come from.

Side Leather vs. Nubuck

Nubuck is a type of top-grain leather that has been sanded or buffed on the grain side to create a soft, velvety surface. Its definition is entirely based on this finish. A piece of side leather can be used as the base material to create nubuck.

Side Leather vs. Full-Grain

Full-grain leather refers to the outermost layer of the hide, with its natural grain and imperfections left intact. While a piece of side leather can be full-grain, the term "side leather" is more commonly associated with corrected-grain leather, where imperfections are buffed out and an artificial grain is applied.

Understanding the Trade-offs

Choosing side leather involves balancing its significant advantages against its inherent characteristics. It is a workhorse material, but not always the choice for every application.

The Advantage: Adaptability and Consistency

The primary benefit of side leather is its role as a "jack-of-all-trades." Its ability to take on different finishes makes it suitable for everything from rugged boots to formal dress shoes. Its large, consistent size makes it highly efficient for mass production.

The Limitation: The "Canvas" Effect

Because side leather is often corrected and embossed, it can sometimes lack the unique, natural character of a high-end full-grain leather. The final quality is entirely dependent on the skill of the tannery and the specific finishing processes applied.

Making the Right Choice for Your Goal

Your choice of leather should be directly informed by the intended function, aesthetic, and price point of the footwear.

- If your primary focus is versatility and cost-effective production: Side leather is the ideal choice, providing a reliable foundation for a wide range of styles.

- If your primary focus is a luxurious, velvety feel: A specialized material like Nubuck is the correct path, but you must account for its higher maintenance needs.

- If your primary focus is unparalleled durability and unique, natural character: Seek out premium full-grain leather, which proudly displays the authentic surface of the hide.

Ultimately, recognizing that side leather is a starting point, not an endpoint, is the key to leveraging its full potential in your design.

Summary Table:

| Feature | Side Leather | Nubuck | Full-Grain Leather |

|---|---|---|---|

| Definition | Defined by its cut (split hide) | Defined by its velvety finish | Defined by its natural, uncorrected grain |

| Versatility | High (can be embossed, tumbled, oiled) | Low (specific finish) | Medium (natural look only) |

| Best For | Mass production, varied styles | Luxurious, soft-feel products | High durability, natural character |

| Production Efficiency | High (large, uniform sides) | Varies | Lower (more natural variation) |

Ready to source the perfect leather for your footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can guide you in selecting the ideal materials—like versatile side leather—for your specific needs. Contact our experts today to discuss your project and benefit from our extensive manufacturing experience!

Visual Guide

Related Products

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Leather Business Casual Shoes with Dial Closure - Manufacturer of Comfort Dress Sneakers

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- How can you determine the correct boot size? A Step-by-Step Guide to a Perfect Fit

- How should insoles and laces be cleaned? Simple Steps for Fresher, Longer-Lasting Footwear

- What role does Carbon-nanofiller Polyethylene Film play within a piezoresistive sensor array for footwear?

- Why is it important for retail workers to choose the right shoes? Prevent Fatigue & Injury

- What is the primary function of electrospinning equipment? Elevate Flexible Footwear with Advanced Nanofiber Technology

- Why is the integration of electrospinning technology and 3D printing significant? Advanced Foot Ulcer Care Solutions

- What role does a force-plate treadmill play in validating the accuracy of wearable footwear sensors? The Gold Standard for Precision.

- How does reinforcing skill identity affect worker mutual assistance? Optimize Flexibility in Footwear Manufacturing