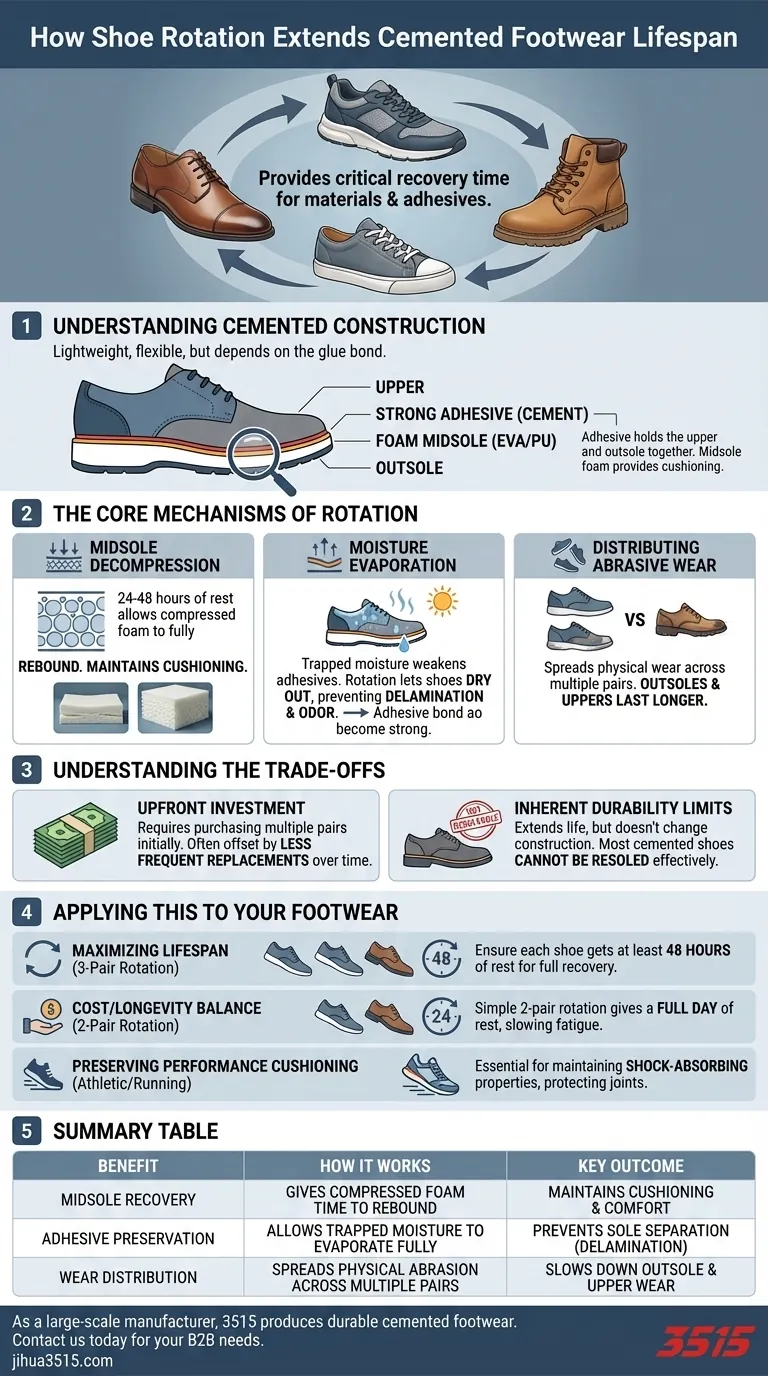

Yes, rotating your shoes absolutely extends the lifespan of cemented footwear. The primary reason is that it provides critical recovery time for the shoe’s materials, especially the cushioning and the adhesives that hold it together. This simple habit prevents the accelerated breakdown that occurs with daily, continuous use.

The core issue with cemented shoes isn't just outsole wear; it's the degradation of the foam midsole and the adhesive bond. Shoe rotation directly addresses this by allowing the compressed materials to decompress and trapped moisture to fully evaporate, preserving both comfort and structural integrity.

What "Cemented Construction" Means

The Role of Adhesives

In cemented construction, the shoe's outsole is attached directly to the upper using a strong adhesive or "cement." There is no stitching holding them together.

This method is lightweight, flexible, and cost-effective, which is why it's common in sneakers, casual shoes, and many dress shoes. However, the shoe's entire structure depends on the integrity of that glue bond.

The Critical Midsole Material

Most cemented shoes feature a midsole made of a foam compound like EVA (ethylene vinyl acetate) or polyurethane (PU).

This layer provides the essential cushioning and comfort but is susceptible to breaking down over time from repeated impact and compression.

The Core Mechanisms of Shoe Rotation

Midsole Decompression and Recovery

With every step you take, the foam cells in the midsole compress to absorb impact. Continuous daily wear doesn't give these cells enough time to expand back to their original shape.

Allowing a shoe to rest for at least 24-48 hours lets the foam fully decompress. This process, known as "rebound," is crucial for maintaining the shoe's cushioning and supportive properties over the long term.

Moisture Evaporation and Adhesive Integrity

Your feet release moisture throughout the day, which gets absorbed by the shoe's inner materials. This trapped moisture can weaken the adhesives used in cemented construction, leading to delamination—where the sole begins to separate from the upper.

Rotation gives a shoe ample time to dry out completely. This preserves the glue's bond and prevents the growth of odor-causing bacteria.

Distributing Abrasive Wear

The most obvious benefit is the simplest one: you are spreading out the physical wear and tear across multiple pairs.

Fewer steps in any single pair means the outsole rubber, upper materials, and inner lining last significantly longer before they are physically worn through.

Understanding the Trade-offs

The Upfront Investment

The most significant drawback is the need to purchase multiple pairs of shoes, which requires a higher initial financial outlay.

However, this cost is often offset over time, as you will replace all the shoes in your rotation far less frequently.

Inherent Durability Limits

Rotation extends a shoe's life, but it doesn't change its fundamental construction. Unlike Goodyear-welted shoes, most cemented shoes cannot be resoled effectively.

Once the outsole wears through or the adhesive bond fails permanently, the shoe has typically reached the end of its functional life.

How to Apply This to Your Footwear

- If your primary focus is maximizing lifespan: Implement a three-pair rotation to ensure each shoe gets at least 48 hours of rest, which is ideal for full material recovery.

- If your primary focus is balancing cost and longevity: A simple two-pair rotation is highly effective and guarantees a full day of rest, significantly slowing down material fatigue.

- If your primary focus is preserving performance cushioning: For athletic or running shoes, rotation is essential to maintain the shock-absorbing properties of the midsole, protecting both the shoe and your joints.

By treating shoe rotation as a fundamental part of footwear care, you protect your investment and ensure better comfort and performance from every pair you own.

Summary Table:

| Benefit of Rotation | How It Works | Key Outcome |

|---|---|---|

| Midsole Recovery | Gives compressed foam (EVA/PU) time to rebound. | Maintains cushioning and comfort. |

| Adhesive Preservation | Allows trapped moisture to evaporate fully. | Prevents sole separation (delamination). |

| Wear Distribution | Spreads physical abrasion across multiple pairs. | Slows down outsole and upper wear. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable cemented footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair is built with quality materials designed to last longer, especially when cared for properly. Looking for reliable, long-lasting footwear for your inventory? Contact us today to discuss your needs and explore our extensive catalog of shoes and boots.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- How can someone determine the appropriate business casual dress code for a new job? Get it Right from Day One

- What materials are suitable for a rugged, casual look in cowboy boots? Distressed & Oiled Leathers Are Key

- How did Clarks contribute to the popularity of desert boots? Masterful Refinement and Global Style

- How has the definition of business casual shoes evolved? From Rigid Rules to Modern Versatility

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- What are the characteristics of urban or casual motorcycle boots? Style Meets Safety for the Everyday Rider

- Which type of boot is considered more formal, Chukka or Desert boots? The Definitive Guide to Business & Casual Footwear

- What are Slip-Ons best used for? The Ultimate Guide to Effortless Casual Footwear