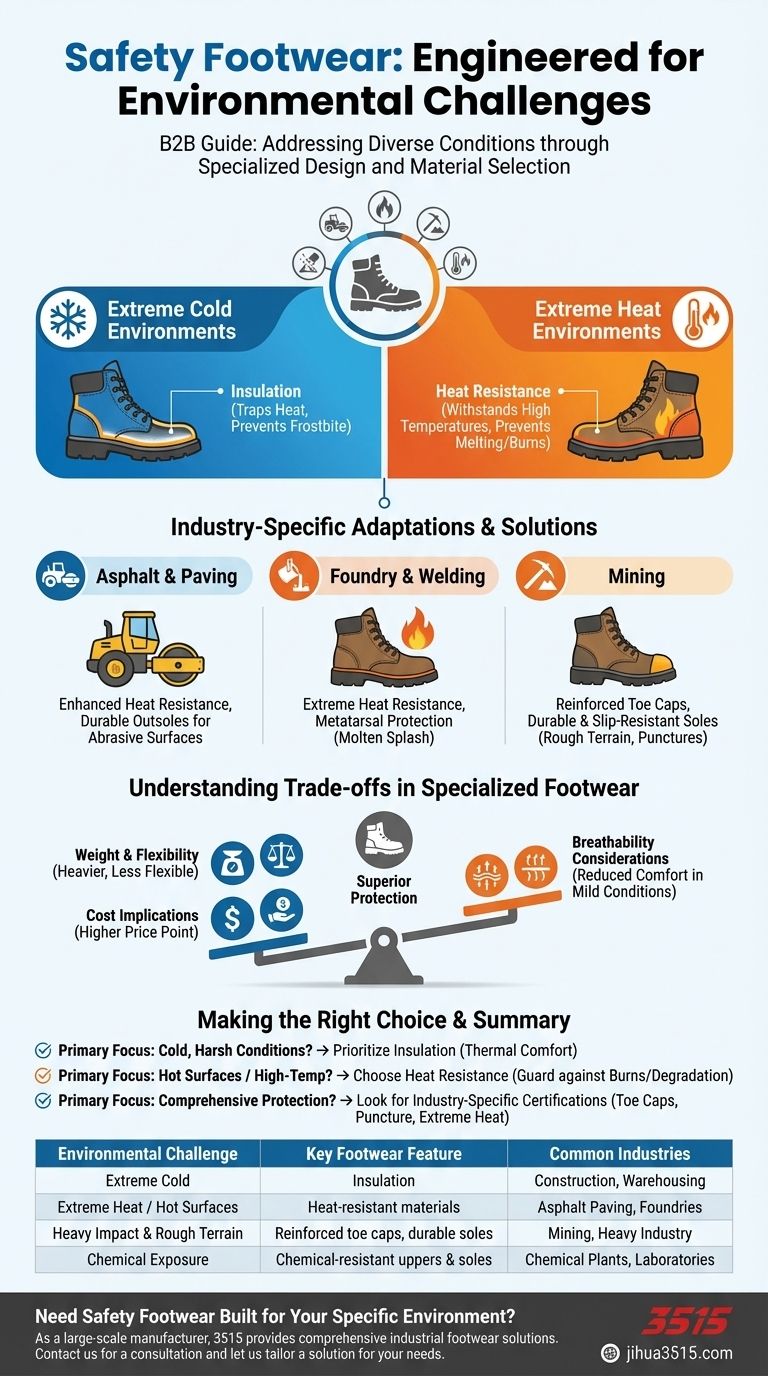

Safety footwear addresses diverse environmental conditions through specialized design and material selection, integrating features tailored to protect against specific hazards like extreme temperatures, impacts, and chemical exposures. This targeted engineering ensures both protection and comfort for workers in demanding environments.

Safety footwear is meticulously engineered to counter environmental challenges, incorporating specific features like insulation for cold and heat resistance for hot surfaces. This specialization provides optimal protection and comfort, adapting the footwear to the unique demands of various industries and conditions.

Specialized Design for Environmental Protection

Safety footwear is not a one-size-fits-all solution; its effectiveness stems from deliberate design choices that cater to the unique demands of various work environments. These designs integrate materials and construction methods to mitigate specific environmental risks.

Responding to Extreme Temperatures

Footwear is specifically engineered to protect against both extreme heat and cold. This is crucial for maintaining worker safety and performance in harsh conditions.

Features for Cold Environments

Footwear designed for cold conditions incorporates insulation. This feature helps to trap heat, preventing significant heat loss from the feet and reducing the risk of frostbite and discomfort. Insulation layers are often integrated into the boot's construction.

Features for Hot Environments

For hot surfaces or environments, safety footwear includes heat resistance. This involves using materials that can withstand high temperatures without degrading, melting, or transferring excessive heat to the wearer's foot. This is vital in fields like asphalt paving or foundries.

Industry-Specific Adaptations

Different industries present unique environmental challenges that require specific footwear features. These adaptations go beyond temperature control to ensure comprehensive protection.

Asphalt/Paving Footwear

Footwear for asphalt and paving work often features enhanced heat resistance for hot surfaces. Durable outsoles are also common to withstand abrasive materials and provide stability.

Foundry and Welding Footwear

In foundry and welding environments, footwear is designed with extreme heat resistance and often includes metatarsal protection. This guards against molten metal splash and high-temperature contact.

Mining Footwear

Mining operations require robust footwear that can withstand rough terrain, potential punctures, and impacts. Features like reinforced toe caps and durable, slip-resistant soles are paramount.

Understanding the Trade-offs

While specialized safety footwear offers superior protection, its specific features can introduce certain trade-offs that users should consider. These are inherent to optimizing for extreme conditions.

Weight and Flexibility

Specialized materials like heavy-duty insulation or heat-resistant compounds can increase the overall weight of the footwear. This might reduce flexibility compared to general-purpose safety boots.

Cost Implications

Advanced features and specialized materials often lead to a higher manufacturing cost. This translates to a greater purchase price for highly specialized environmental footwear.

Breathability Considerations

Footwear with extensive insulation or water-resistant barriers, while protective, might sometimes have reduced breathability. This can affect comfort in less extreme conditions or during extended wear.

Making the Right Choice for Your Goal

Selecting appropriate safety footwear requires a clear understanding of the specific environmental hazards present in your work. Matching the footwear's features to these conditions is paramount.

- If your primary focus is protection in cold, harsh conditions: Prioritize footwear with robust insulation to maintain thermal comfort and prevent cold-related injuries.

- If your primary focus is protection on hot surfaces or in high-temperature environments: Choose footwear specifically rated for heat resistance to guard against burns and material degradation.

- If your primary focus is comprehensive protection across demanding industrial settings (e.g., mining, foundry): Look for footwear with industry-specific certifications that include features like reinforced toe caps, puncture resistance, and extreme heat protection.

Understanding the specific environmental challenges and the corresponding specialized features of safety footwear ensures optimal protection and comfort for every worker.

Summary Table:

| Environmental Challenge | Key Footwear Feature | Common Industries |

|---|---|---|

| Extreme Cold | Insulation for heat retention | Construction, Warehousing |

| Extreme Heat / Hot Surfaces | Heat-resistant materials | Asphalt Paving, Foundries |

| Heavy Impact & Rough Terrain | Reinforced toe caps, durable soles | Mining, Heavy Industry |

| Chemical Exposure | Chemical-resistant uppers & soles | Chemical Plants, Laboratories |

Need Safety Footwear Built for Your Specific Environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including insulated models for cold storage, heat-resistant boots for foundries, and rugged footwear for mining operations.

We help you ensure worker safety and compliance by providing footwear engineered to address your unique environmental challenges. Contact us today for a consultation and let us tailor a solution for your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the main components of safety shoes? A Guide to Protective Footwear Design

- What protection does puncture-resistant (PR) footwear provide? A Shield Against Hidden Hazards

- How do steel, aluminium, and composite toe caps compare? Choose the Right Safety Toe for Your Job

- What role does a virtual last play within a customized safety shoe production system? The Digital DNA of Footwear Design

- What is the primary role of an industrial-grade automated electrical performance testing machine for safety shoes?

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What is the importance of understanding OSHA safety shoe standards? Ensure Compliance and Protect Your Workforce

- Why do industrial-grade pressure-sensing insoles use a three-zone layout? Optimize Biomechanical Data Accuracy