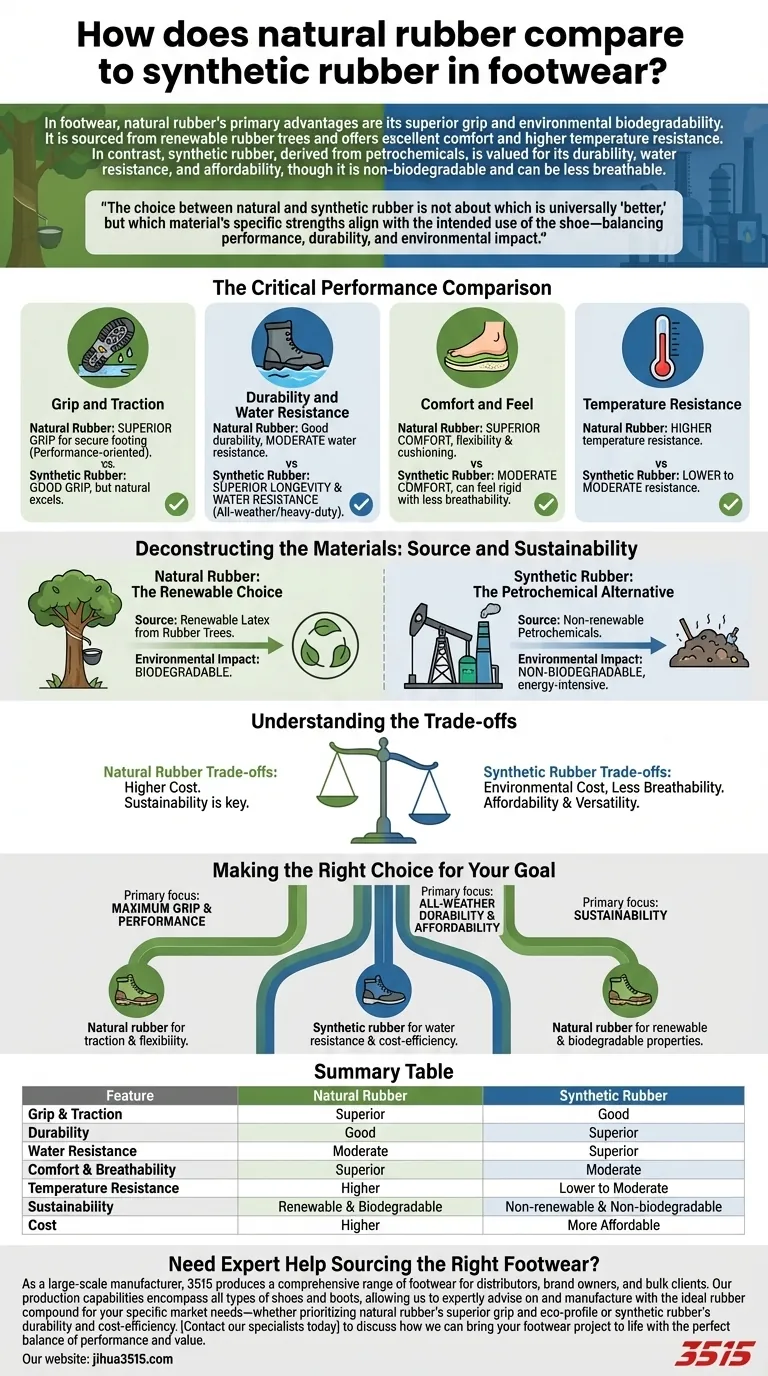

In footwear, natural rubber's primary advantages are its superior grip and environmental biodegradability. It is sourced from renewable rubber trees and offers excellent comfort and higher temperature resistance. In contrast, synthetic rubber, derived from petrochemicals, is valued for its durability, water resistance, and affordability, though it is non-biodegradable and can be less breathable.

The choice between natural and synthetic rubber is not about which is universally "better," but which material's specific strengths align with the intended use of the shoe—balancing performance, durability, and environmental impact.

The Critical Performance Comparison

Understanding how each material performs in real-world conditions is essential for choosing the right footwear. The differences in their physical properties directly translate to your experience with grip, comfort, and longevity.

Grip and Traction

Natural rubber has a molecular structure that provides superior grip and traction on various surfaces. This makes it a preferred material for performance-oriented footwear where secure footing is critical.

Durability and Water Resistance

Synthetic rubber is engineered for longevity and resistance. It often outperforms natural rubber in terms of abrasion resistance and is inherently more water-resistant, making it a common choice for all-weather boots and heavy-duty work shoes.

Comfort and Feel

Natural rubber is known for providing excellent comfort due to its inherent flexibility and cushioning properties. While modern synthetics have improved, they can sometimes feel more rigid and may offer less breathability, potentially reducing comfort over extended wear.

Temperature Resistance

A key technical difference is heat tolerance. Natural rubber has a higher temperature resistance, maintaining its integrity and performance in hotter conditions. Synthetic rubbers typically have a low to moderate temperature resistance.

Deconstructing the Materials: Source and Sustainability

The origin of these materials dictates their environmental footprint and renewability. This is an increasingly important factor for many consumers and manufacturers.

Natural Rubber: The Renewable Choice

Natural rubber is a renewable resource harvested as latex from the Hevea brasiliensis, or rubber tree. Because it is a plant-based polymer, it is also biodegradable, allowing it to break down naturally at the end of its life cycle.

Synthetic Rubber: The Petrochemical Alternative

Synthetic rubber is a polymer created from petrochemicals, a non-renewable resource. This manufacturing process is energy-intensive, and the final product is non-biodegradable, contributing to long-term landfill waste.

Understanding the Trade-offs

Neither material is a perfect solution. The decision to use one over the other involves balancing performance benefits against practical and environmental costs.

The Environmental Cost

The most significant trade-off is sustainability. Natural rubber offers a "cradle-to-grave" solution that is renewable and biodegradable. Synthetic rubber's reliance on fossil fuels and its persistence in the environment present a clear ecological downside.

The Price and Versatility Factor

Synthetic materials are often more affordable and easier to manufacture in a wide variety of colors, textures, and styles. This versatility makes them a staple in modern sports shoes and cost-effective footwear.

The Breathability Dilemma

While not always the case, many synthetic materials, especially those designed for water resistance, offer less breathability than their natural counterparts. This can impact foot comfort, particularly in warm conditions or during strenuous activity.

Making the Right Choice for Your Goal

To select the appropriate footwear, align the material's core strengths with your primary needs.

- If your primary focus is maximum grip and performance: Natural rubber offers the superior traction and flexibility required for demanding activities.

- If your primary focus is all-weather durability and affordability: Synthetic rubber provides a reliable, water-resistant, and cost-effective solution for everyday and rugged use.

- If your primary focus is sustainability: Natural rubber is the clear choice for its renewable sourcing and biodegradability.

Ultimately, understanding these material properties empowers you to choose footwear that truly serves its intended purpose.

Summary Table:

| Feature | Natural Rubber | Synthetic Rubber |

|---|---|---|

| Grip & Traction | Superior | Good |

| Durability | Good | Superior |

| Water Resistance | Moderate | Superior |

| Comfort & Breathability | Superior | Moderate |

| Temperature Resistance | Higher | Lower to Moderate |

| Sustainability | Renewable & Biodegradable | Non-renewable & Non-biodegradable |

| Cost | Higher | More Affordable |

Need Expert Help Sourcing the Right Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to expertly advise on and manufacture with the ideal rubber compound for your specific market needs—whether prioritizing natural rubber's superior grip and eco-profile or synthetic rubber's durability and cost-efficiency.

Contact our specialists today to discuss how we can bring your footwear project to life with the perfect balance of performance and value.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Wholesale Durable Camouflage Canvas Shoes with High-Traction Cleated Rubber Sole

People Also Ask

- How does natural rubber contribute to shock absorption in footwear? Unlock Superior Comfort & Durability

- How does the execution of a 44-point trajectory by a robot arm ensure high-quality shoe sole gluing? 1.2mm Precision

- Why is 60 Shore A hardness rubber used for turf friction tests? Mastering Industry Footwear Standards

- What is a vulcanized sole? Discover the Secret to Superior Flexibility and Grip

- How does a friction coefficient test rig facilitate the assessment of slip resistance in rubber footwear soles?

- What is the best way to clean rubber soles? Restore Your Shoes with Simple Household Items

- Why is a specific lateral bevel machined onto the leading edge of rubber sliders? Ensure Friction Testing Accuracy

- Can hunters wear all brown or green rubber pull-on boots instead of camo boots? Yes, and Here’s Why.